Method and device for applying a decorative layer

A decorative layer and coating technology, applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of affecting the production cycle, high energy consumption of mold heating, slow mold heating, etc., to improve the cooling effect and improve the cooling effect effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

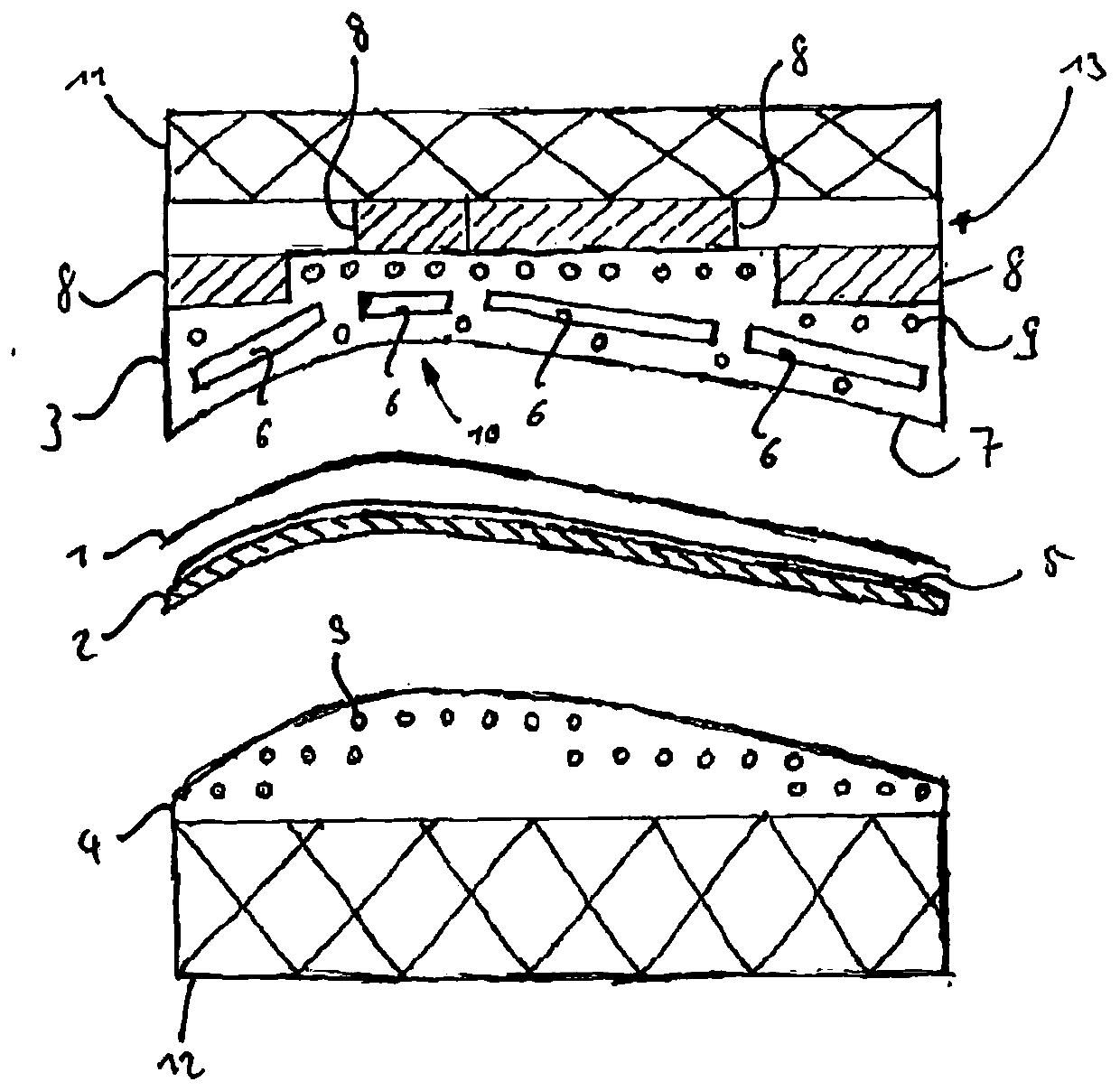

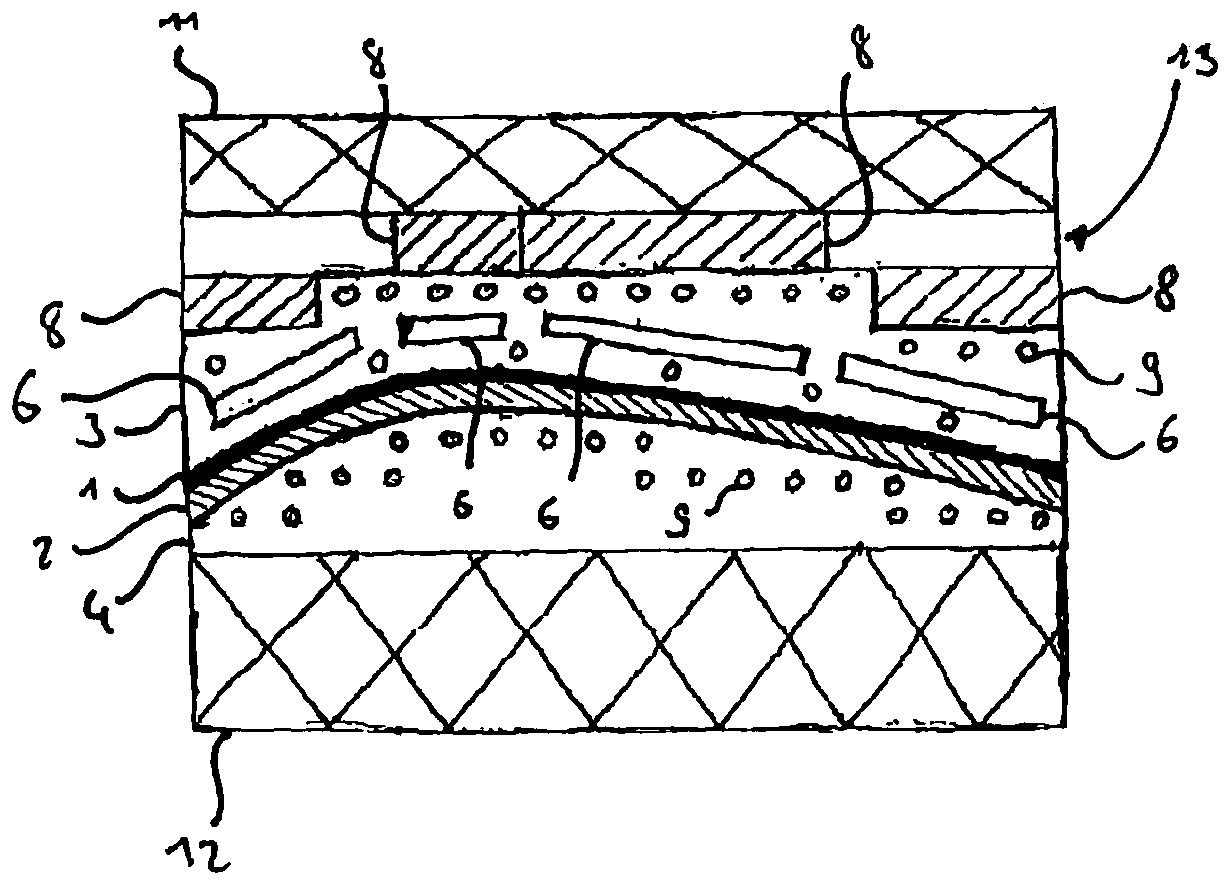

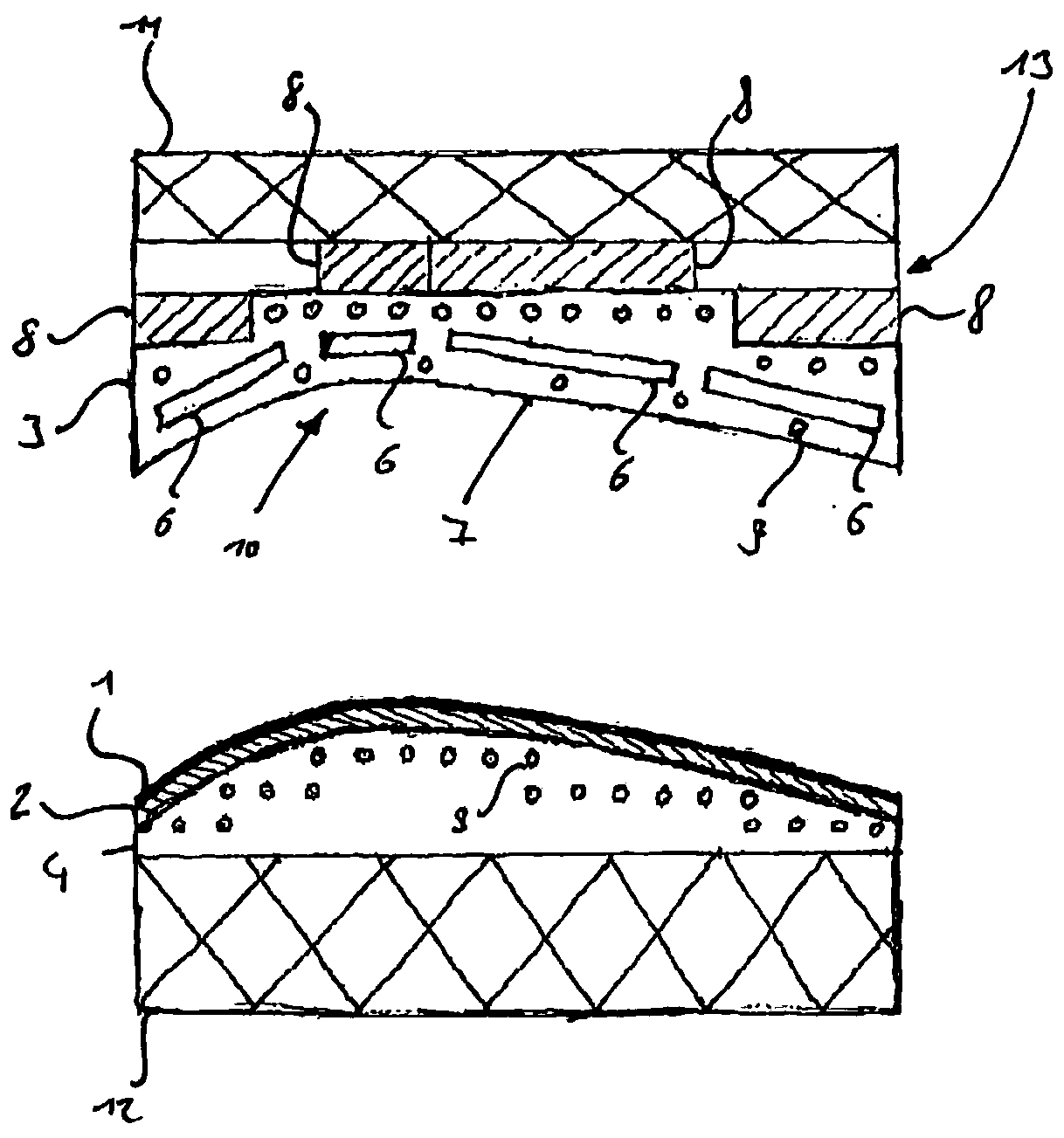

[0050] Figures 1 to 3 The production method according to the invention is shown in a device according to the invention. The device according to the invention comprises a first mold half 3 and a second mold half 4 . A decorative part 2 and a decorative layer 1 are embedded between the half-mold 3 and the half-mold 4 . Furthermore, a heat-activated adhesive 5 is applied between the decorative layer 1 and the decorative part 2 . Here, the first mold half 3 and the second mold half 4 have a contour corresponding to the outer contour of the decorative part 2 . Both the first half-mold 3 and the second half-mold 4 are provided with cooling channels 9 throughout. Here, the cooling channels 9 are mainly arranged on the side of the mold half facing the decoration 2 and the decoration layer 1 . An inductively heatable insert 6 is also introduced into the first mold half 3 . In this embodiment, the insert 6 is completely enclosed by the remaining area of the first mold half 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com