Printing mechanism of cloth printing assembly line

A printing mechanism and assembly line technology, applied in the direction of printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problems that affect the efficiency of ink filling, the ink scraping device cannot effectively scrape ink, and the printing is not accurate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

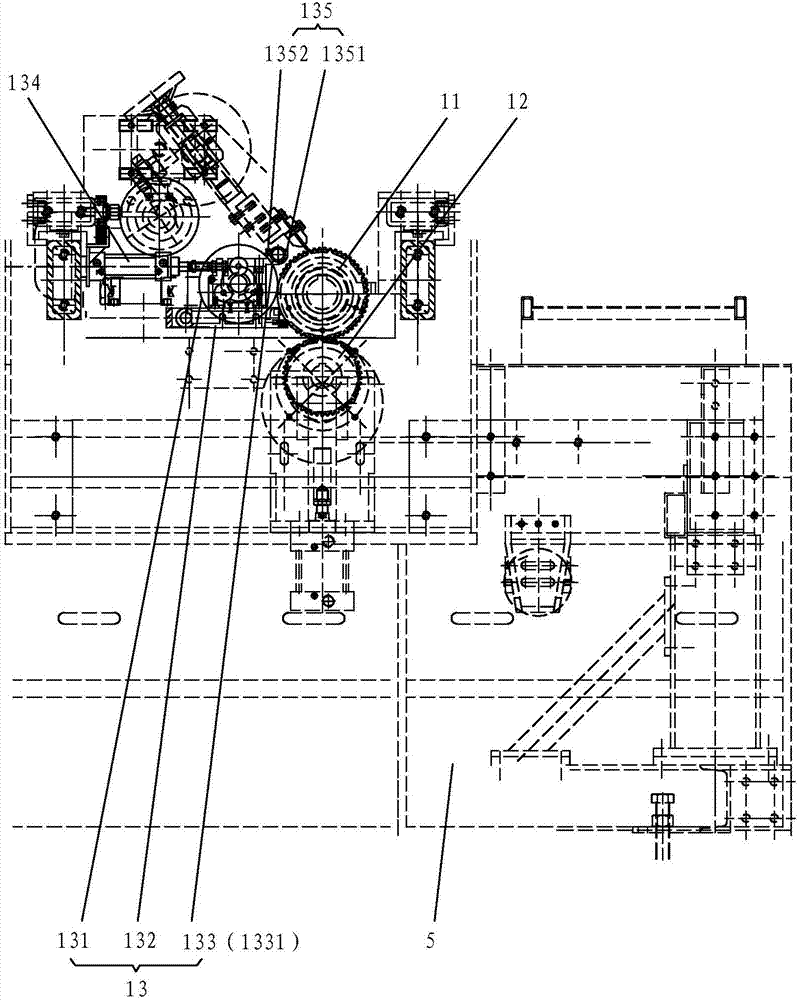

[0075] The printing mechanism of a kind of cloth printing assembly line of the present invention, as Figure 1-11 As shown, it includes a printing device, a printing support corresponding to the printing device and carrying part of the printing device, a printing correction device for correcting the printing device, and a scraper device for scraping the ink.

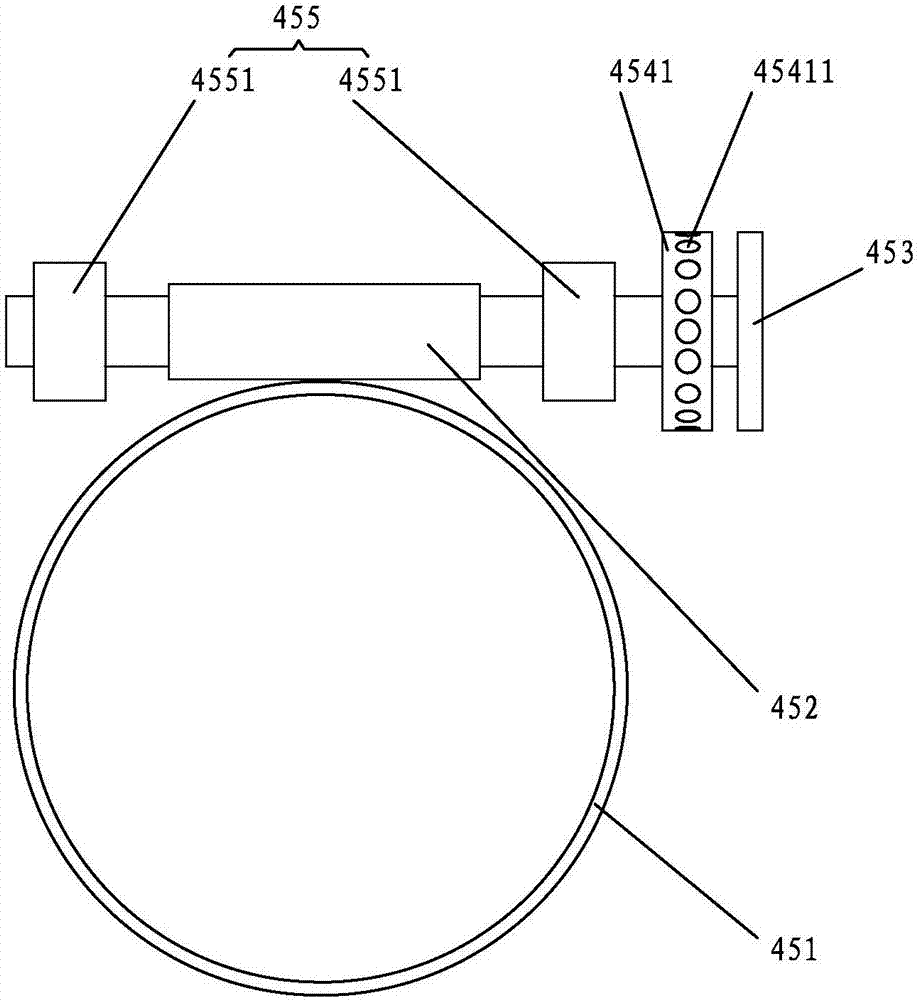

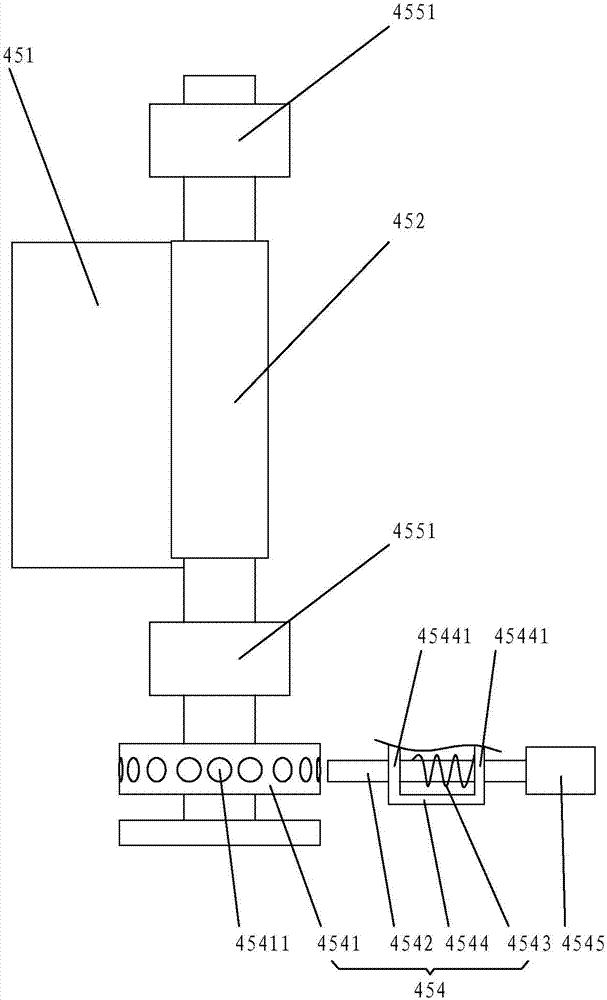

[0076]The printing device includes a printing roller 11 above which directly prints the cloth and a resisting roller 12 which is below the conveyor belt (the conveyor belt for conveying the cloth, not shown in the figure); the printing roller 11 is equipped with a Inking device 13; Inking device 13 comprises the inking roller 131 that directly contacts with printing roller 11 and carries out inking, the ink groove 132 that is used to hold ink below the inking roller 131, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com