Method of using square-recess embedded substrate support to inhibit growth of polycrystalline diamond

A technology of polycrystalline diamond and single crystal diamond, which is applied in the field of preparation of single crystal diamond materials, can solve problems such as uneven temperature on the surface of single crystal diamond substrate, affecting the surface quality and crystal size of single crystal diamond, and edge polycrystalline growth, etc. , to achieve the effect of avoiding polycrystalline growth, optimizing temperature uniformity, and suppressing edge polycrystalline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] (1) Making a square groove mosaic substrate holder

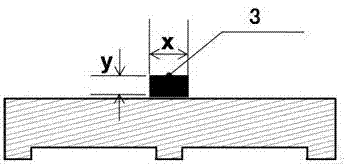

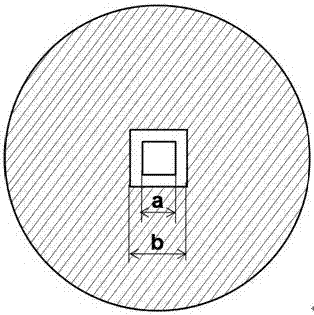

[0040] a) According to the specifications of the single crystal diamond substrate, the MPCVD substrate holder is made according to the design drawings, and two concentric square grooves are opened in the center of the surface of the substrate holder; the specification of the square single crystal diamond substrate 3 in this embodiment: side length x is 5mm; the thickness y is 1mm, and the square groove mosaic substrate molybdenum holder is made, the side length a of the bottom square groove 1 is 5.2mm; the side length b of the upper square groove 2 is 6.2mm; the sum of the depth c of the two square grooves is 1.5mm; the depth d of the bottom square groove 1 is 0.5mm.

[0041] b) The surface of the substrate holder and the inside of the groove must be ground and polished.

[0042] c) Ultrasonic cleaning was performed on the surface of the substrate holder with absolute ethanol, and a short-term (10 min) surface plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com