Full-spandex fitting double-sided cloth

A double-sided, all-spandex laminating technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of insufficient recovery force, low spandex content, and poor recovery of the cloth surface, and achieve non-slip and skin-friendly performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

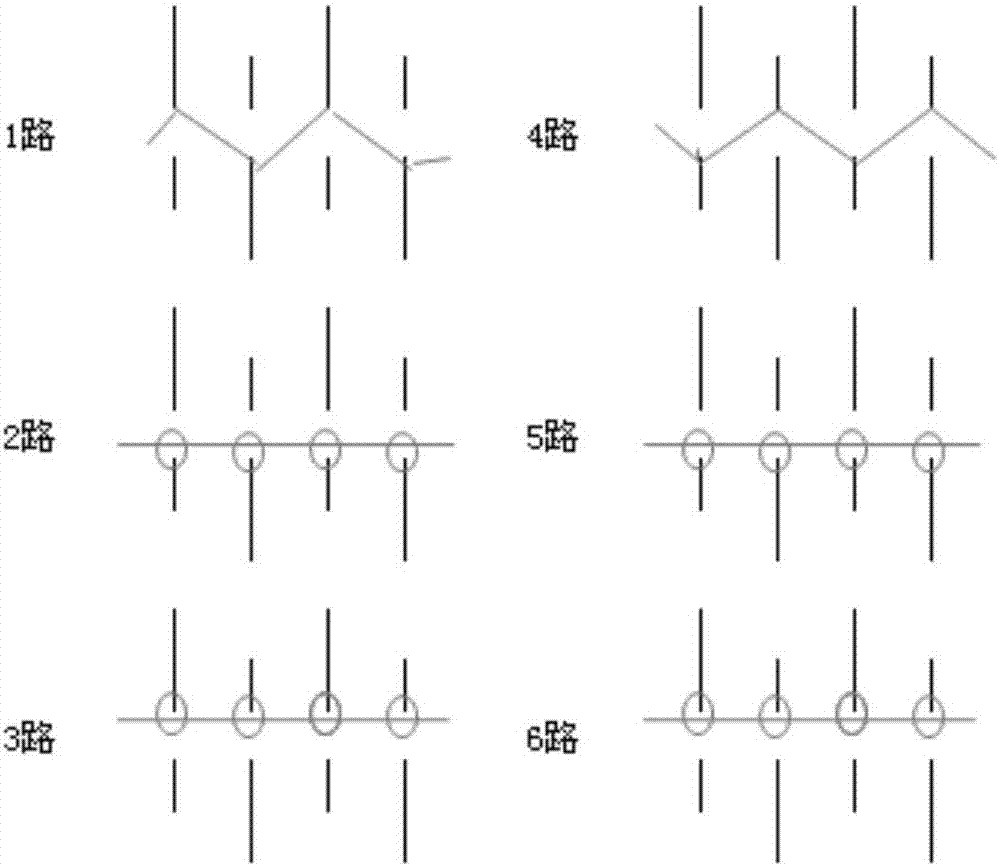

[0017] see Figure 1-Figure 3 , the present invention provides a kind of technical scheme: a kind of all-spandex laminating double-sided cloth, comprises the steps:

[0018] S1: Double needle bed machine is used for weaving, and the number of lines entering the machine is 72;

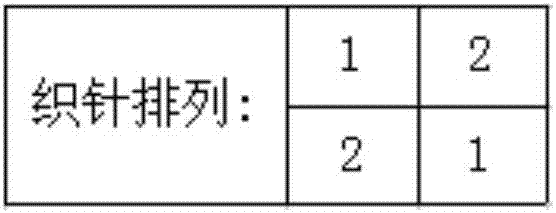

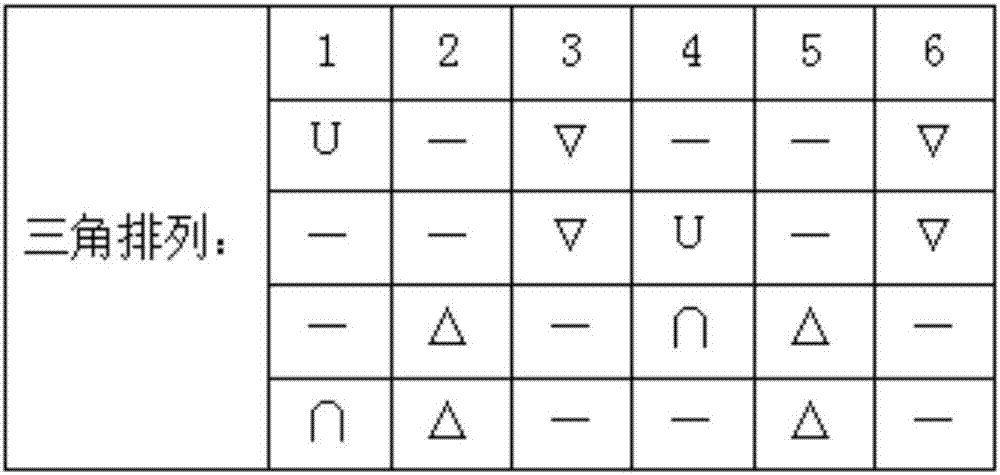

[0019] S2: Among the 72 routes, each 6-way incoming line is a cycle. In this process, one and four-way and a half lines are woven with PU 20D, and the second, third, fifth and sixth lines are woven with PU 70D on one side;

[0020] S3: The rolling cloth seal on the double-needle bed machine is controlled at 96CM, the warp density on the double-needle bed machine is 40 threads / CM, and the machine speed of the double-needle bed machine is controlled at 15 rpm.

[0021] Incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yarn length | aaaaa | aaaaa |

| Yarn length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com