Supporting structure for fabricated structure beam plate connection and mounting method

A technology of supporting structures and structural beams, which is applied in the direction of building construction and construction, can solve the problems of cumbersome installation and removal of under-slab supports, insufficient beam lap length, etc., to meet construction safety requirements, reduce the difficulty of formwork support, and facilitate on-site operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

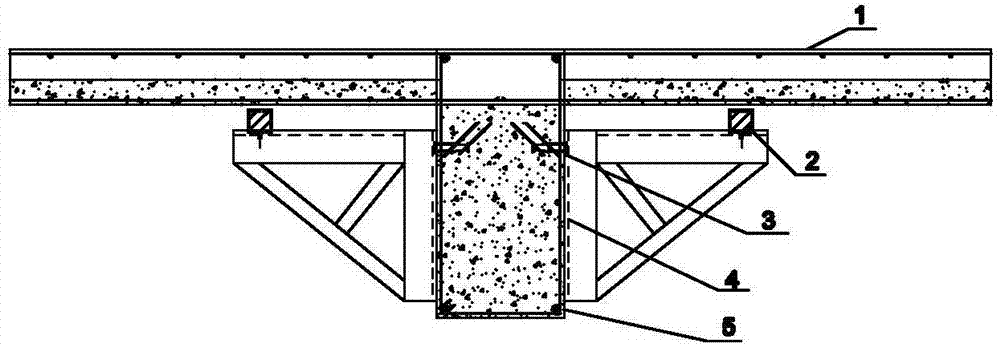

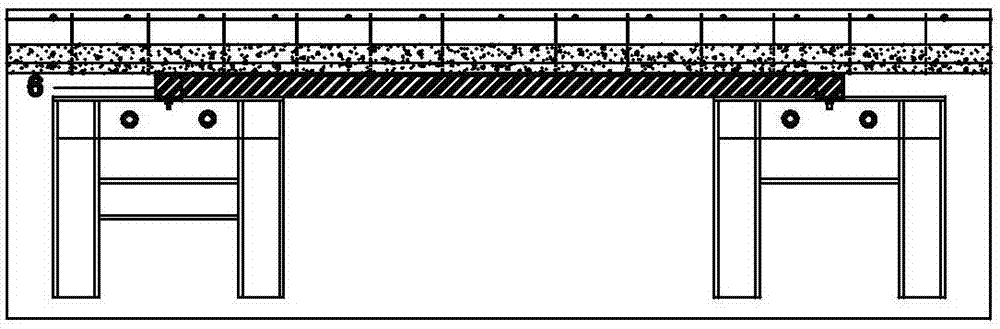

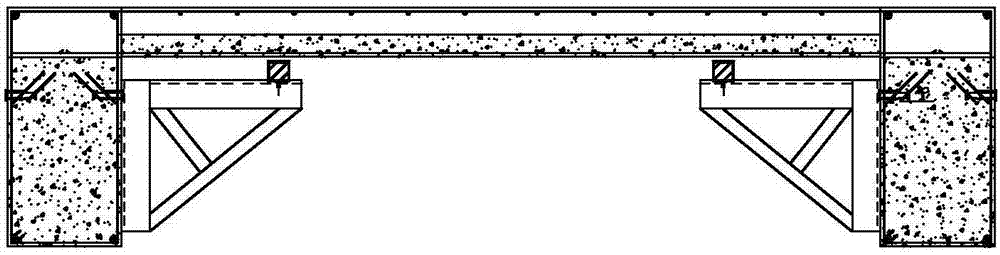

[0043] Example: such as Figure 1-Figure 6 As shown, the present invention is a supporting structure for the connection of assembled structural beams and slabs, including the support frame 4 symmetrically arranged on both sides of the composite beam 5, the adjustment frame 2 and the support plate arranged between the support frame 4 and the composite plate 1 6. Two support frames 4 are arranged side by side along each side of the laminated beam 5. The cross section of the support frame 4 is a triangular frame structure, and its right-angled sides correspond to the laminated beam 5 and the laminated plate 1 respectively, and the opposite side of the laminated beam 5 Bolt connection holes are provided on the right-angled side of the composite beam 5, which are connected to the embedded nut 3 provided on the side of the composite beam 5; The adjustment frame 2 on the support frame 6 is connected with a support plate 6, and the laminated plate 1 is placed above the support plate 6...

Embodiment 2

[0058] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the outer periphery of the embedded nut 3 provided on the composite beam 5 in this embodiment is provided with U-shaped ribs, and the angle α inclined relative to the horizontal plane is 30°. What this example support plate 6 adopted is the wooden side. like Figure 9 , Figure 10 As shown, there is a stopper 8 at the end of the embedded nut 3 not connected to the bolt in this example, and the stopper 8 is arranged in a cross-shaped structure along the circumference of the end, which is convenient for installation and fixation.

Embodiment 3

[0059] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the embedded nut 3 provided on the composite beam 5 in this embodiment is provided with a U-shaped rib on the outer periphery, and the angle α inclined relative to the horizontal plane is 40°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com