Support system and assembly method for large-sized oblique woven gusset plate lattice shell structure

A technology of support system and gusset plate, which is applied in the direction of arch structure, dome roof structure, building components, etc., can solve the problems of complex structure and construction difficulty of woven gusset plate reticulated shell, and achieve improved civilized construction and convenient operation. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below through specific embodiments and accompanying drawings. The embodiments of the present invention are for better understanding of the present invention by those skilled in the art, and do not limit the present invention in any way.

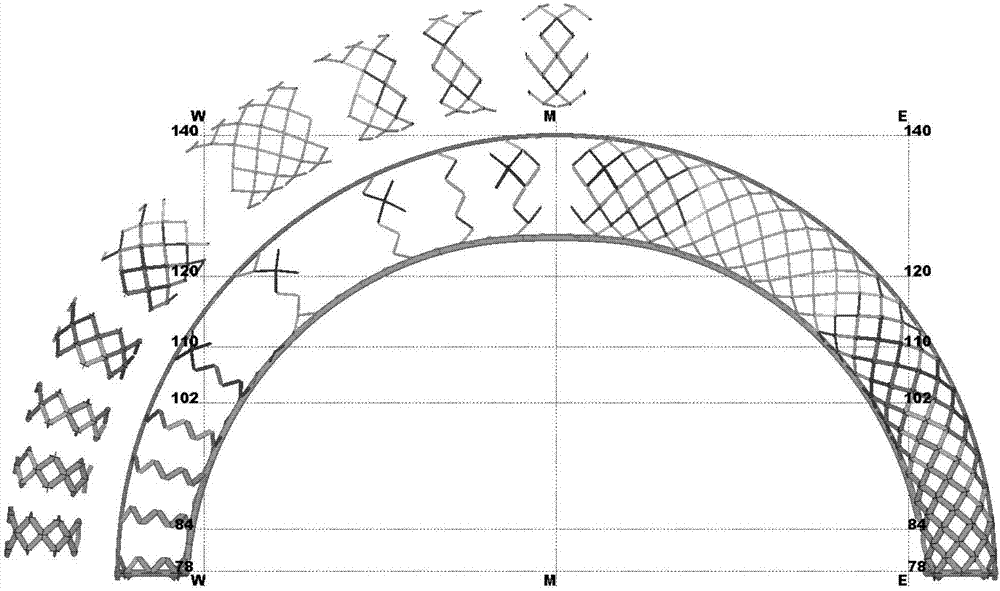

[0035] The support system of the large-scale diagonal braided gusset plate reticulated shell structure of the present invention includes a foundation treatment part, a main support structure installed on the foundation treatment part, and chord positioning steel pipes located on both sides of the main support structure:

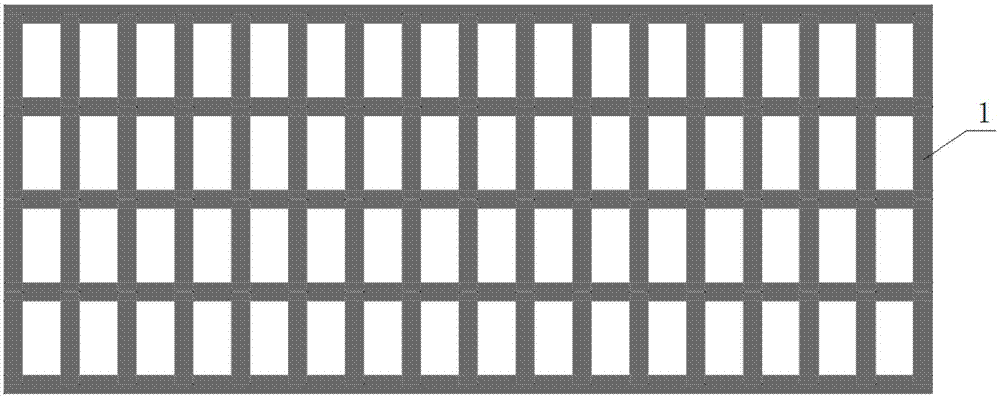

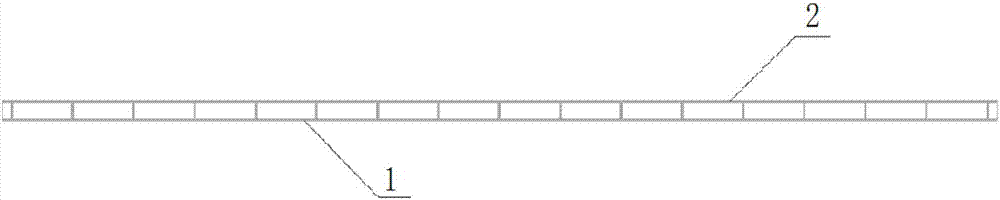

[0036] (a), foundation treatment part: consists of a base concrete platform and a steel platform installed on the base concrete platform, such as figure 1 As shown, the steel platform is composed of a well-shaped keel 1 and a steel plate 2 covered thereon; the steel plate 2 is punched and spot-welded with the keel 1, and the upper part of the steel plate 2 is super flat;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com