Spring-clip-limited dustproof rolling bearing

A kind of rolling bearing and dustproof technology, applied in rolling contact bearings, rotating bearings, bearings, etc., can solve the problems of limited dustproof capacity, unbearable, large axial force, etc., to improve the dustproof sealing effect, improve Structural stability, good effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

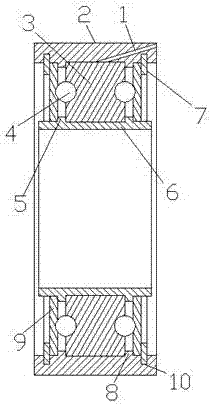

[0016] Combine below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0017] A dust-proof rolling bearing with a spring clamp position, comprising: a bearing outer ring 2 and a bearing inner ring 6, the bearing inner ring 6 is concentrically arranged in the bearing outer ring 2, the inner wall of the bearing outer ring 2 and the bearing inner ring A circle of cylindrical rotating body 3 is arranged between 6 for rolling connection, and the radial support effect is good.

[0018] The bearing outer ring 2 is provided with sealing rings 9 located on both sides of the cylindrical rotating body 3 for dust-proof sealing, and balls 4 are respectively arranged between the inner surface of the sealing ring 9 and the end of the cylindrical rotating body 3 for rolling. connected to increase the axial support strength of the cylindrical swivel 3, the bearing outer ring 2 is respectively provided with spring clips 7 located outsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com