Pipeline sleeper used for reinforced concrete drainage pipeline

A technology for reinforced concrete and drainage pipes, which is applied in the directions of pipe supports, pipes/pipe joints/pipes, mechanical equipment, etc. It can solve the problems of complicated construction, difficult to control the elevation and straightness of pipes, etc., so as to reduce the construction period and improve the construction. The effect of production safety and improved load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

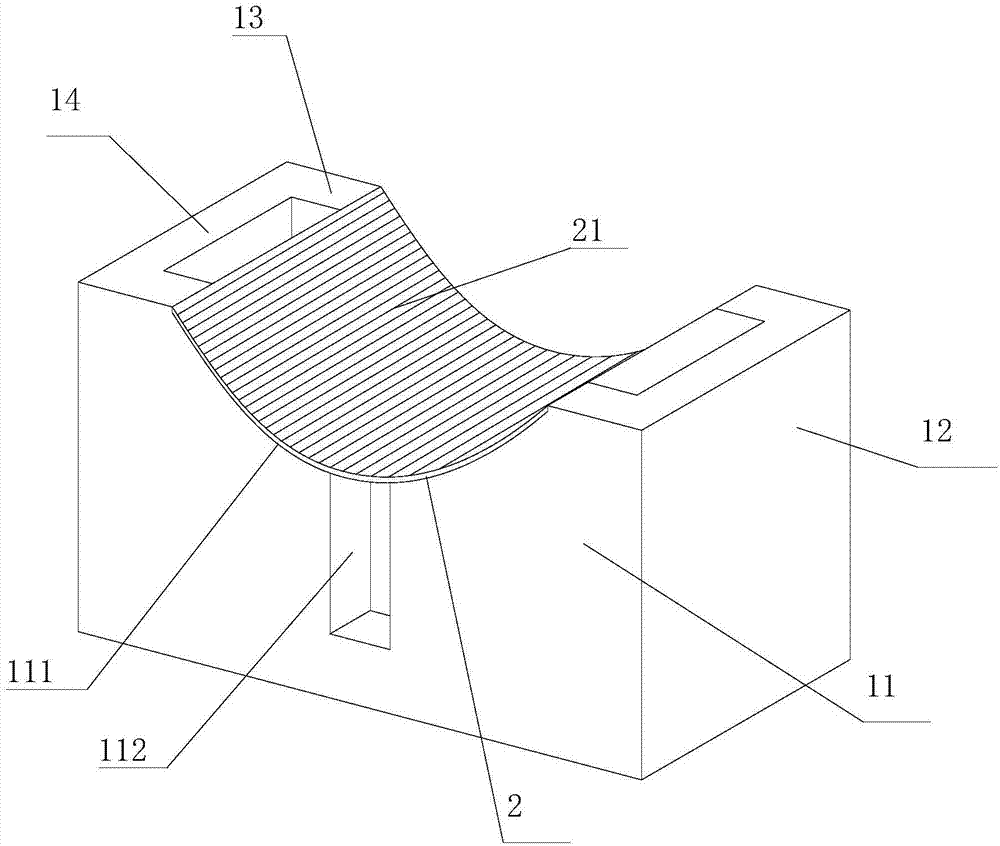

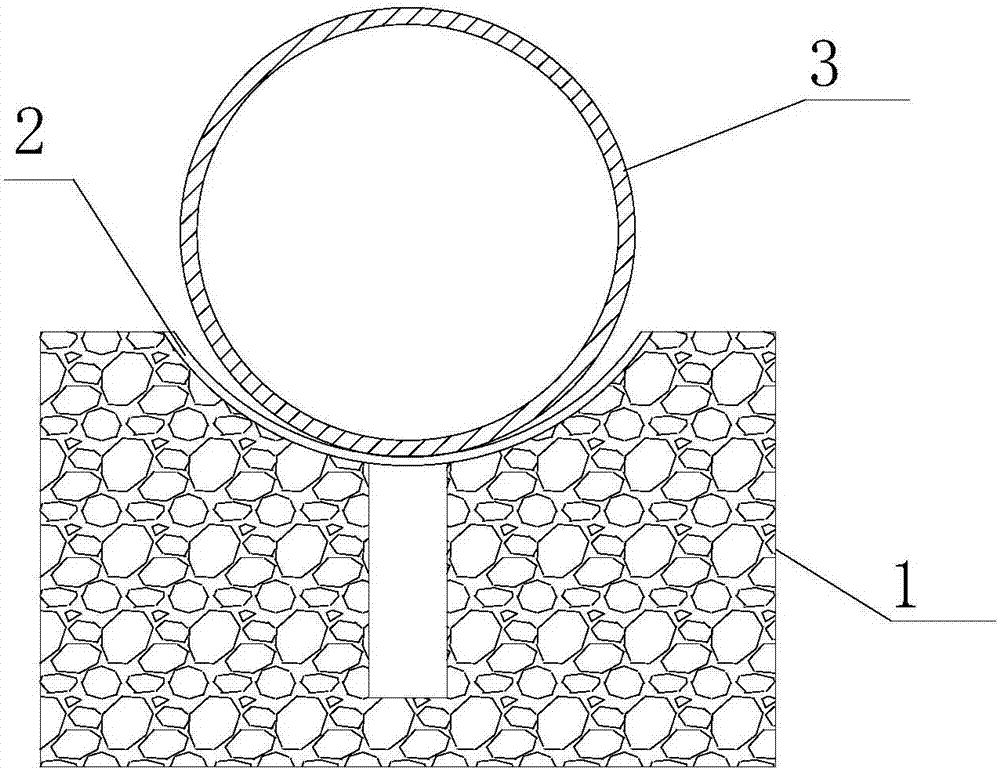

[0022] refer to figure 1 , figure 2 , image 3 , the present invention proposes a pipe pillow for reinforced concrete drainage pipes, including a pillow body 1 in a frame structure and a load-bearing plate 2 for installing the pipe. The pillow body 1 is made of reinforced concrete, and the pillow body 1 includes end-to-end connections in sequence The first side plate 11, the second side plate 12, the third side plate 13, the fourth side plate 14, the first side plate 11, the second side plate 12, the third side plate 13, and the fourth side plate 14 are integrally formed, The first side plate 11 is arranged opposite to the third side plate 13 , and the second side plate 12 is arranged opposite to the fourth side plate 14 . The upper end surfaces of the first side plate 11 and the third side plate 13 are respectively provided with a first groove 111 and a second groove 131 for installing pipes; the first groove 111 and the second groove 131 are arc-shaped, and The central a...

Embodiment 2

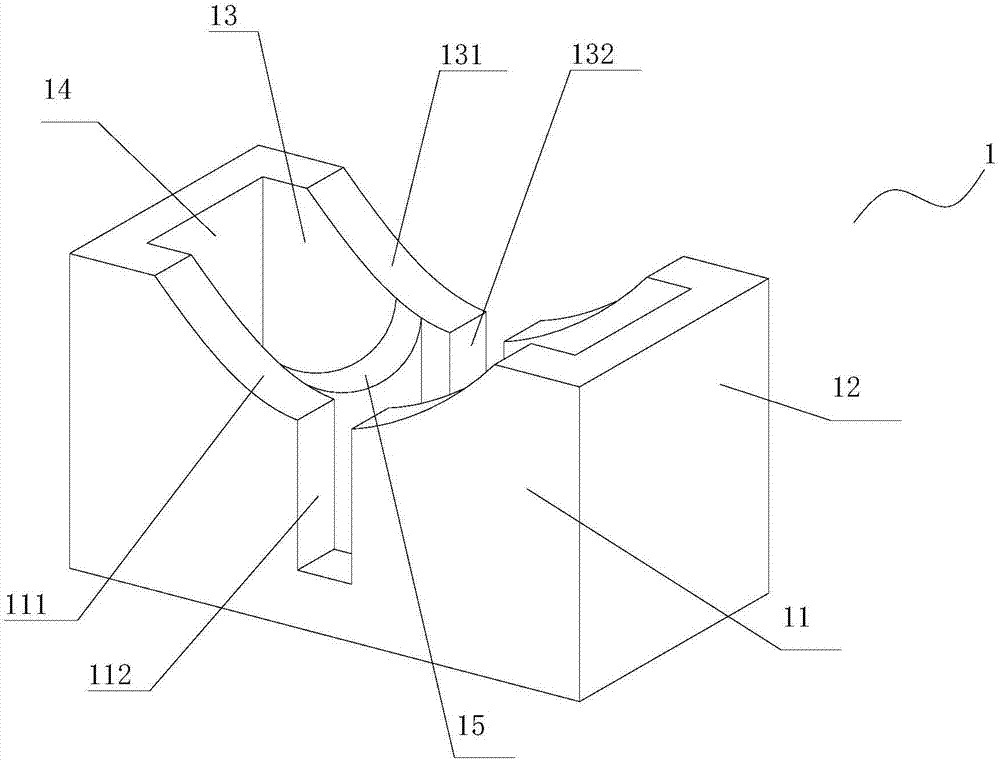

[0024] refer to Figure 4 , Figure 5 , Figure 6 , the present invention proposes a pipe sleeper for reinforced concrete drainage pipes, which includes a pillow body 1 in a frame structure and a load-bearing plate 2 for installing the pipe. The pillow body 1 is made of reinforced concrete, and the pillow body 1 includes a first side plate 11, a second side plate 12, a third side plate 13, a fourth side plate 14 connected end to end in sequence, the first side plate 11, the second side plate The board 12 , the third side board 13 and the fourth side board 14 are integrally formed, the first side board 11 is arranged opposite to the third side board 13 , and the second side board 12 is arranged opposite to the fourth side board 14 . The upper end surfaces of the first side plate 11 and the third side plate 13 are respectively provided with a first groove 111 and a second groove 131 for installing pipes, the first groove 111 and the second groove 131 are V-shaped, and The V-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com