Slope Cutting Method of Shallow Hole Step Controlled Blasting in Road Cutting in Complex Environment

A technology for controlling blasting and complex environments, which is applied in the fields of highway engineering, engineering blasting and rock mechanics, and slope engineering. High operational reliability, reduced risk, and high practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

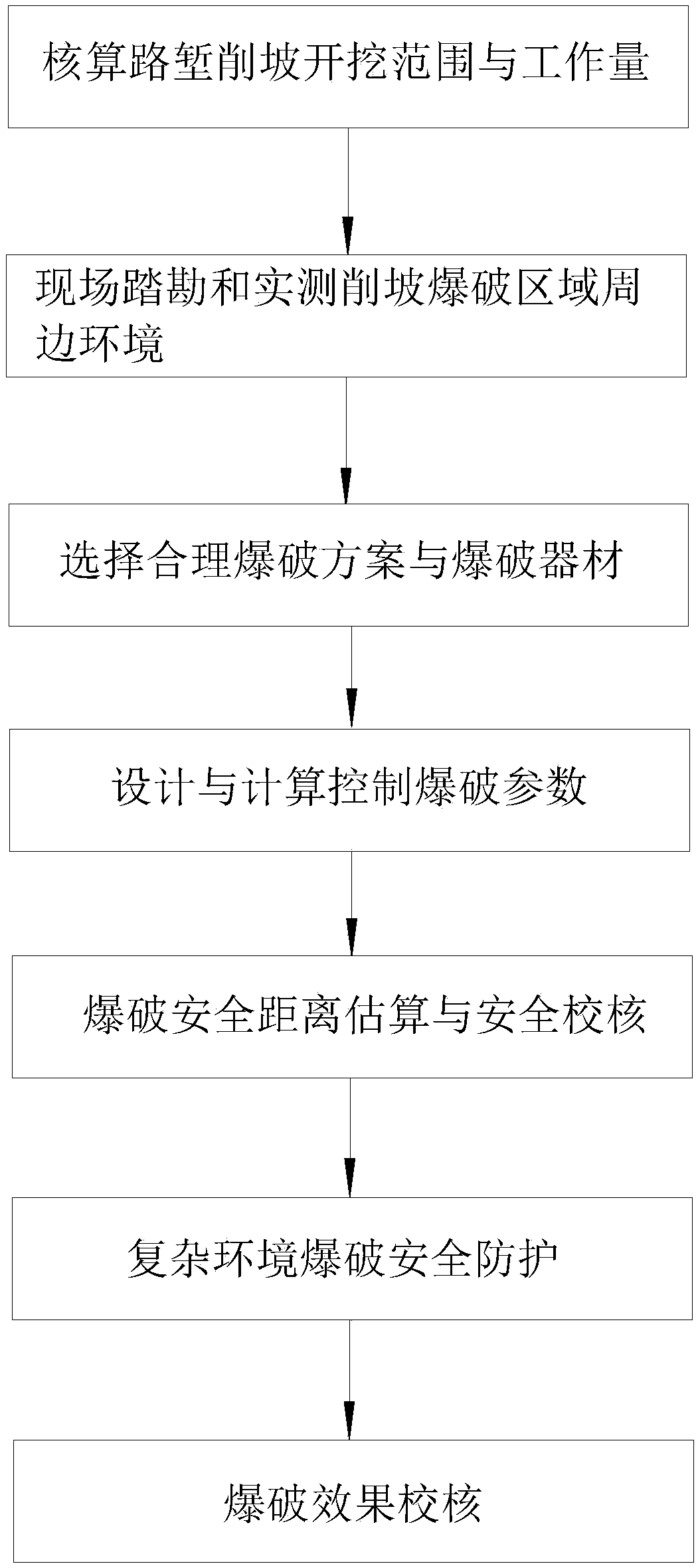

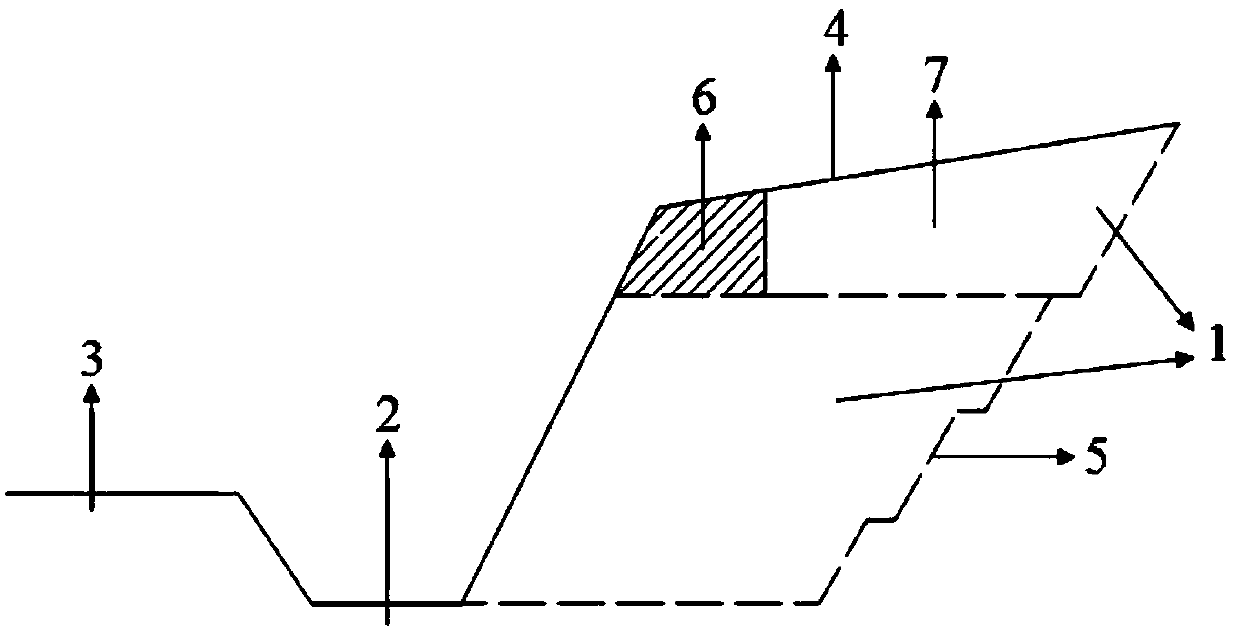

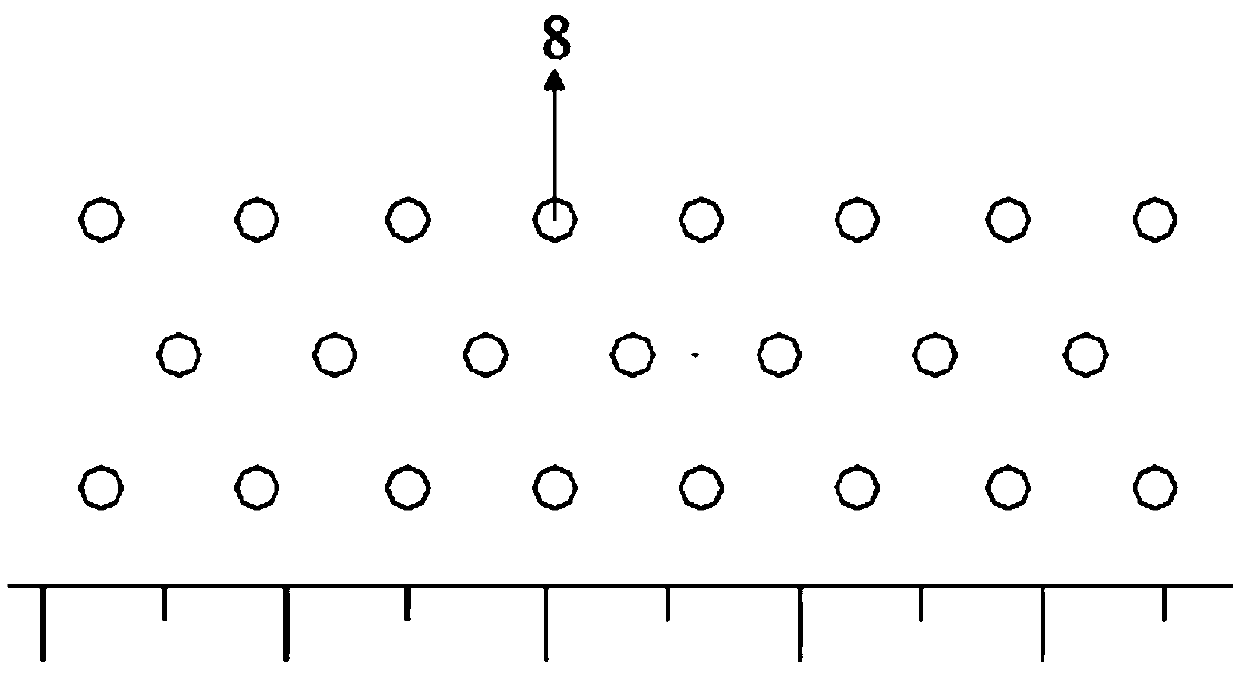

[0060] see figure 1 , the embodiment of the present invention includes:

[0061] A slope cutting method by controlled blasting of shallow hole steps in road cuttings in a complex environment, comprising the following steps:

[0062] (1) Calculating the excavation scope and workload of cutting and slope cutting, including the start and end pile numbers of the excavation section, excavation elevation, excavation height difference, length and volume;

[0063] (2) On-site survey and actual measurement of the surrounding environment of the slope-cutting blasting area, including the location and distance of mountains, buildings or structures, and road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com