Automobile drier leak detection device

A dryer and leak detection technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of inconvenient clamping, low work efficiency, high labor intensity, etc. , to achieve the effect of preventing poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

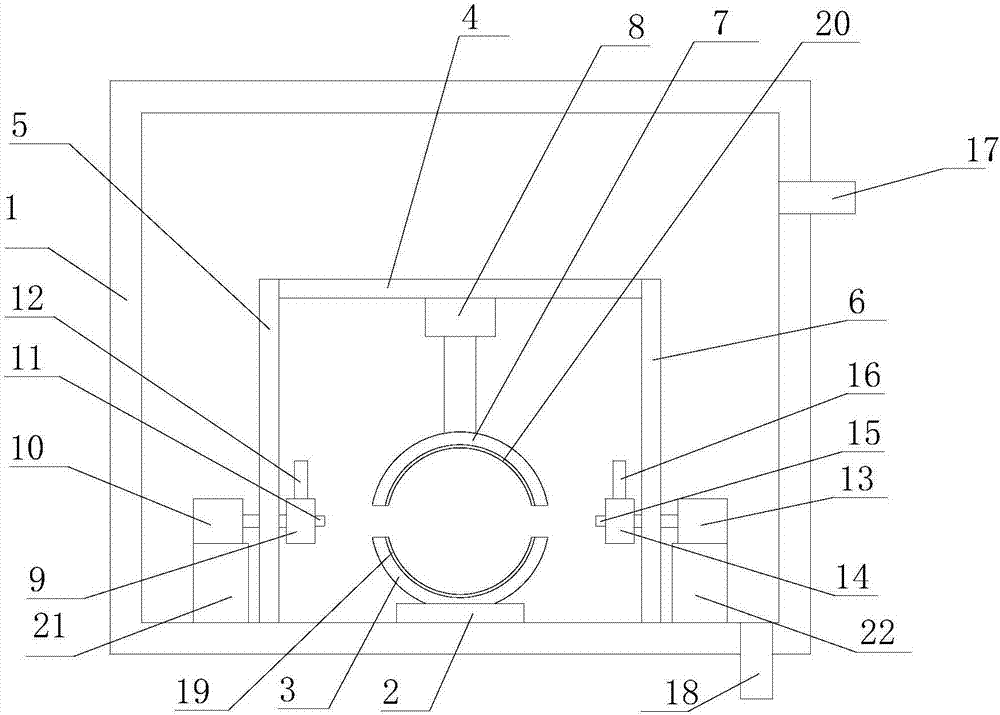

[0017] like figure 1 as shown, figure 1 It is a structural schematic diagram of a leak detection device for an automobile dryer proposed by the present invention.

[0018] refer to figure 1 , the present invention proposes a leak detection device for an automobile dryer, which is used for leak detection of an automobile dryer, including a water tank 1, a clamping member, a first inflatable component, a second inflatable component, an inflatable device, a water filling device and a pumping device ,,in:

[0019] The inner side of the bottom plate of the water tank 1 is provided with a workpiece placement platform 2, and a first arc-shaped supporting plate 3 is installed on the workpiece placing platform 2. The arc-shaped opening of the first arc-shaped supporting plate 3 faces the opening end of the water tank 1. The inner side is provided with a first protective layer 19, a mounting beam 4 is provided above the first arc-shaped supporting plate 3, and first side frames 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com