Method for measuring diffusion process and diffusion coefficient of CO2 between oil-water two-phase

A diffusion coefficient and diffusion process technology, which is applied in the field of measuring the diffusion process and diffusion coefficient of CO2 between oil and water phases, can solve the problems of pressure drop curve fluctuation, complicated measurement process, and processing error, so as to avoid large fluctuations in pressure and improve calculation accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

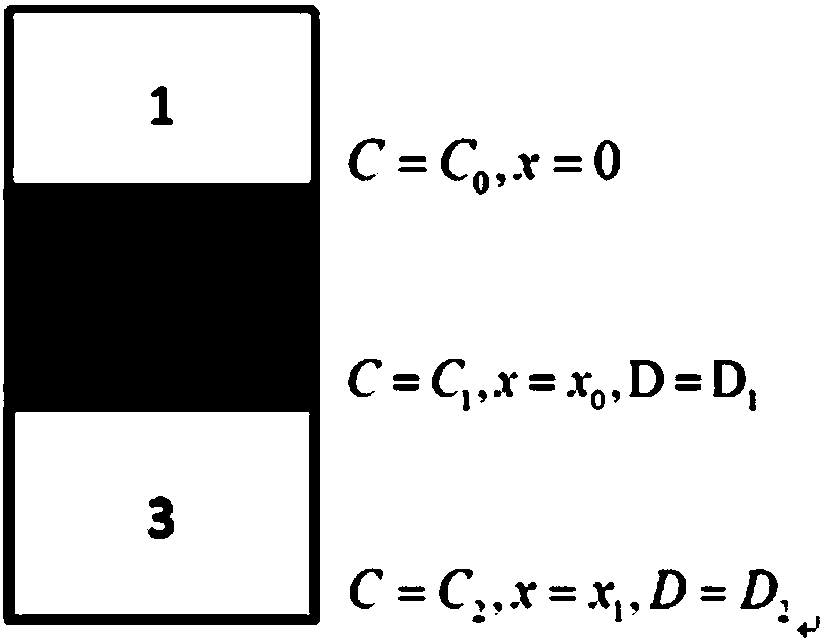

[0061] A predictive CO 2 Through the oil phase to the water phase diffusion process and the method of diffusion coefficient, the implementation steps are as follows:

[0062] (1) Measure the cross-sectional area of the diffusion vessel to be 20cm 2 and the volume V of the diffusion vessel 1 250mL, wash and dry the diffusion vessel and vacuumize it;

[0063] (2) CO 2 Fill the diffusion vessel and increase the pressure to the test pressure of 14.60MPa, the diffusion vessel is externally connected to the back pressure, and the back pressure is equal to the test pressure;

[0064] (3) Inject 92mL of pure water at a temperature of 323.15K from the lower part of the diffusion vessel at a rate of 20mL / min. The injection process is connected to the back pressure to keep the pressure of the diffusion vessel system constant. The height of the water phase is z 0 1.3cm;

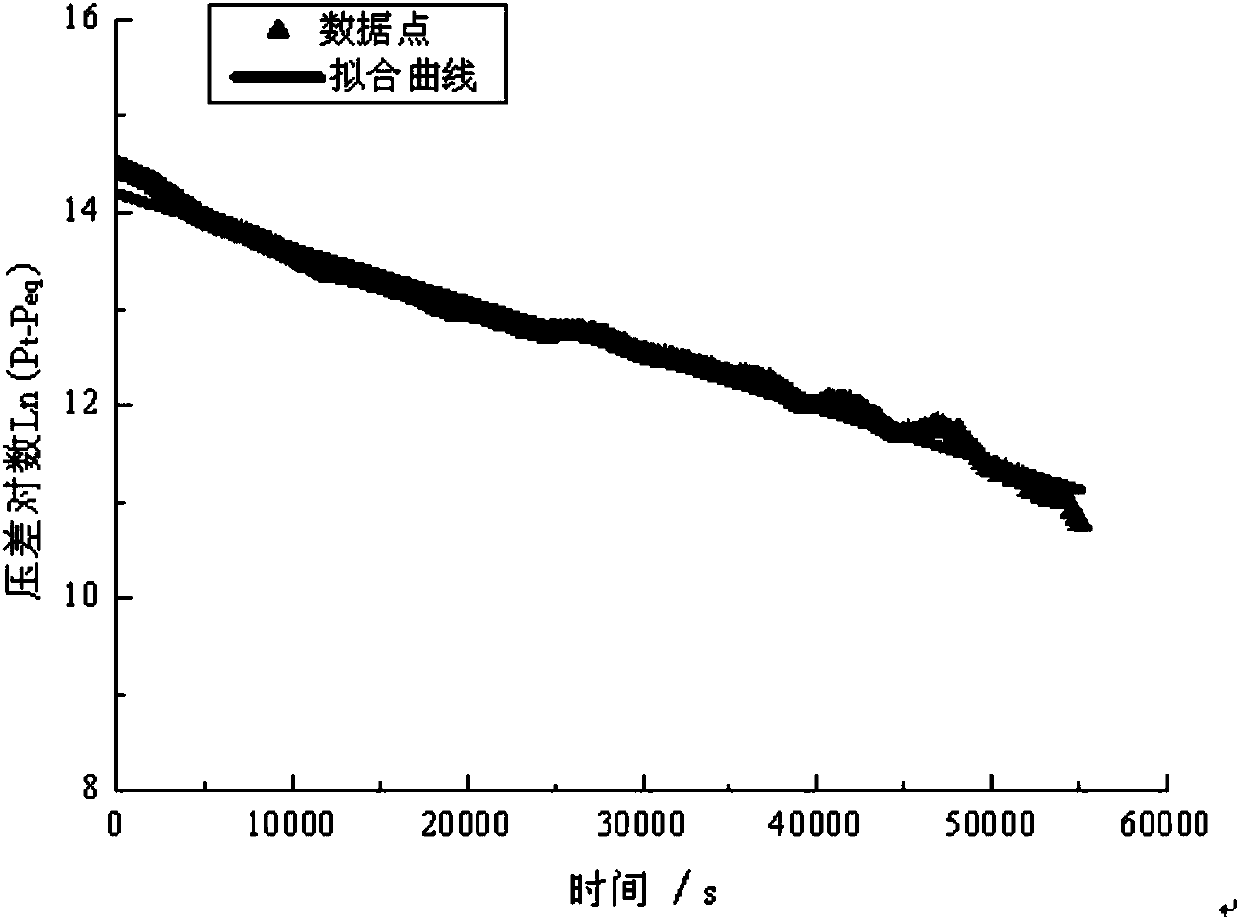

[0065] (4) After the pure water is injected, close the diffusion container, and use the pressure acquisition sy...

Embodiment 2

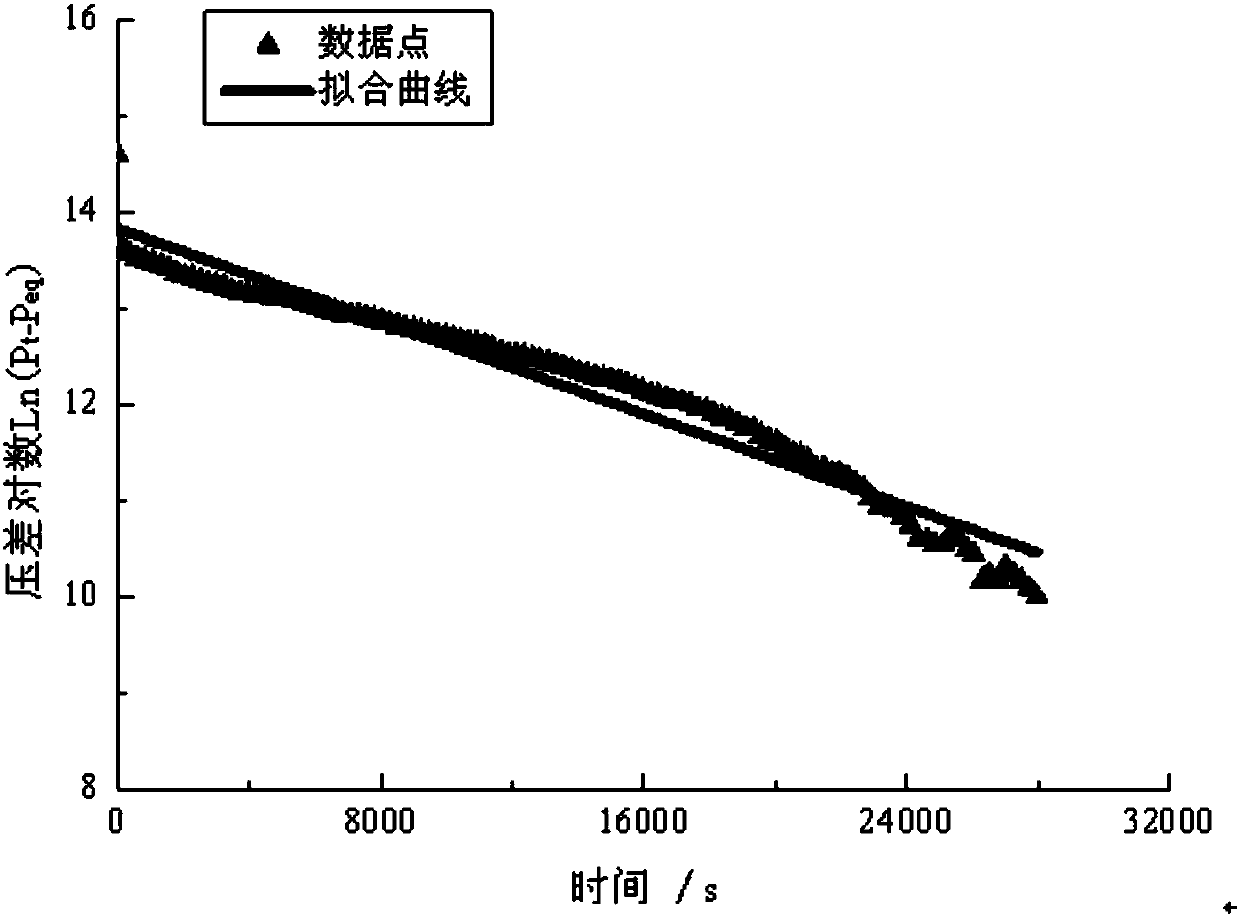

[0097] A measure of CO 2 The method of diffusion process and diffusion coefficient between oil and water two phases, as shown in embodiment 1, difference is:

[0098] The positions of the oil phase and the water phase in the diffusion vessel are exchanged, and the diffusion process is CO 2 The diffusion coefficient can also be measured by this method through the diffusion of the water phase to the oil phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com