Multi-channel precision sample feeding injection pump module

A multi-channel, syringe pump technology for mechanical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

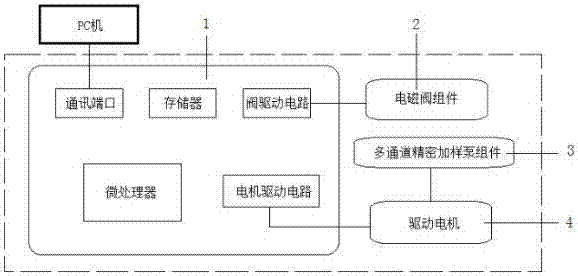

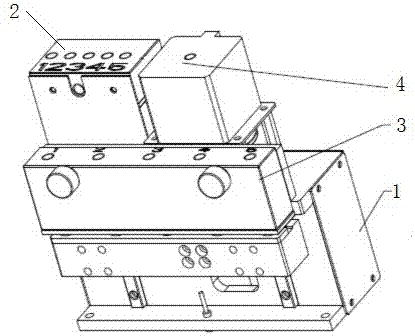

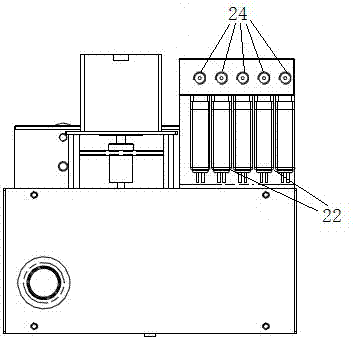

[0018] A multi-channel precision sampling injection pump module, including a control system 1, a solenoid valve assembly 2, a multi-channel precision sampling pump assembly 3, and a drive motor 4; the control system 1 includes a microprocessor, a valve drive circuit, a motor drive circuit and Memory, control system 3 is also provided with communication port; Solenoid valve assembly 2 comprises solenoid valve substrate 21, a plurality of solenoid valves 22 installed on solenoid valve substrate 21 and a solenoid valve In port 23, according to the quantity of solenoid valve 22, solenoid valve The substrate 21 corresponds to a plurality of solenoid valve Out ports 24 and a plurality of solenoid valve Com ports 25; the multi-channel precision sampling pump assembly 3 includes a precision linear drive assembly 31 and a multi-channel plunger pump body assembly 32; the multi-channel plunger pump The body assembly 32 includes a pump body base 320, and the pump body base 320 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com