Motor stator and rotor iron core stamping progressive die adopting dispensing lamination and dispensing process

A technology of stator and rotor adopting points, which is applied in the field of stamping progressive die and dispensing technology of motor stator and rotor iron core, which can solve the problems of reducing the quality of the iron core, affecting the magnetic performance of the iron core, reducing the stamping production efficiency, etc., and achieving the improvement of solidification Effects of speed, improved magnetic performance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

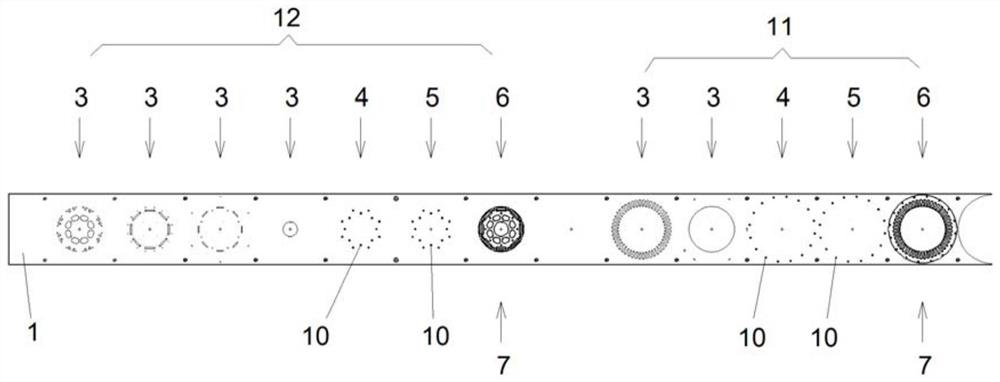

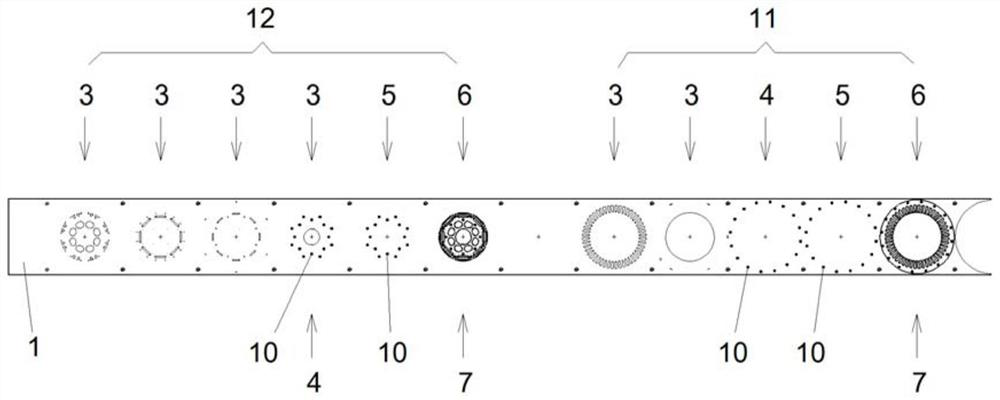

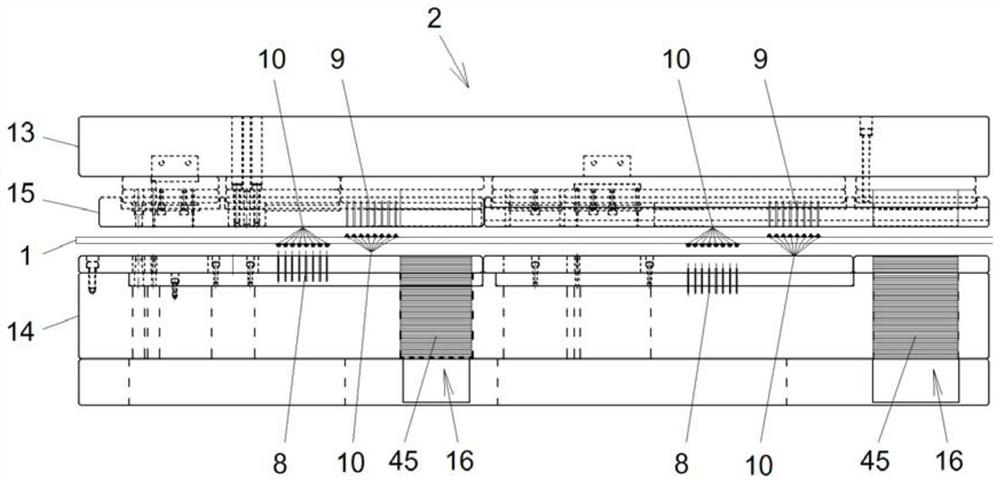

[0094] like Figures 1 to 8 Shown is an embodiment of a stamping progressive die for the stator and rotor iron core of a motor using glue-dispensing lamination, including the progressive die 2 for the stator and rotor iron core stamping of the motor sequentially arranged in accordance with the moving direction of the material strip 1. Stamping station 3, first component glue dispensing station 4, second component glue dispensing station 5 and blanking station 6, the iron core punching sheet is arranged below the blanking station 6 The automatic stacking mechanism 7, and one of the glue dispensing stations of the first component glue dispensing station 4 and the second component glue dispensing station 5 is located above the material belt 1, The other glue dispensing station is located below the material belt 1; wherein, the first component glue dispensing station 4 is provided with a device for dispersing the first component glue material to the material belt The first compon...

Embodiment 2

[0146] A glue dispensing lamination process for a stator and rotor iron core of a motor, comprising the following steps:

[0147](1) Dispensing station setting: On the stator and rotor iron core stamping progressive die 2 of the motor, according to the moving direction of the material belt 1, the stamping station 3, the first component glue dispensing station 4, and the second group are set in order. The glue dispensing station 5 and the blanking station 6 are divided, the iron core punching automatic stacking mechanism 7 is arranged below the blanking station 6, and the first component glue dispensing station 4 And one of the glue dispensing stations of the second component glue dispensing station 5 is located at the upper position of the material belt 1, and the other glue material dispensing station is located at the lower position of the material belt 1; The first-component glue dispensing station 4 is provided with a first-component glue dispensing device 8 for distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com