Fully-automatic microscopic scanner

A fully automatic, scanner technology, applied in the field of microscopic scanning, can solve the problems of low microscopic scanning efficiency and inability to scan liquids, etc., and achieve the effects of easy implementation, improved scanning speed, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

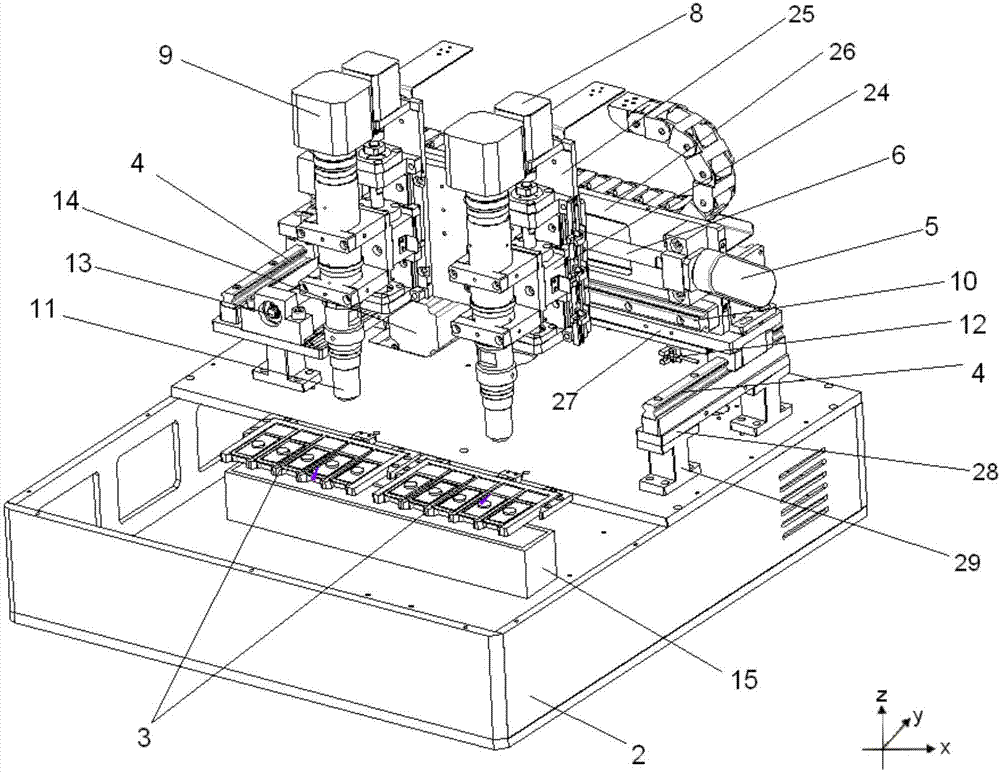

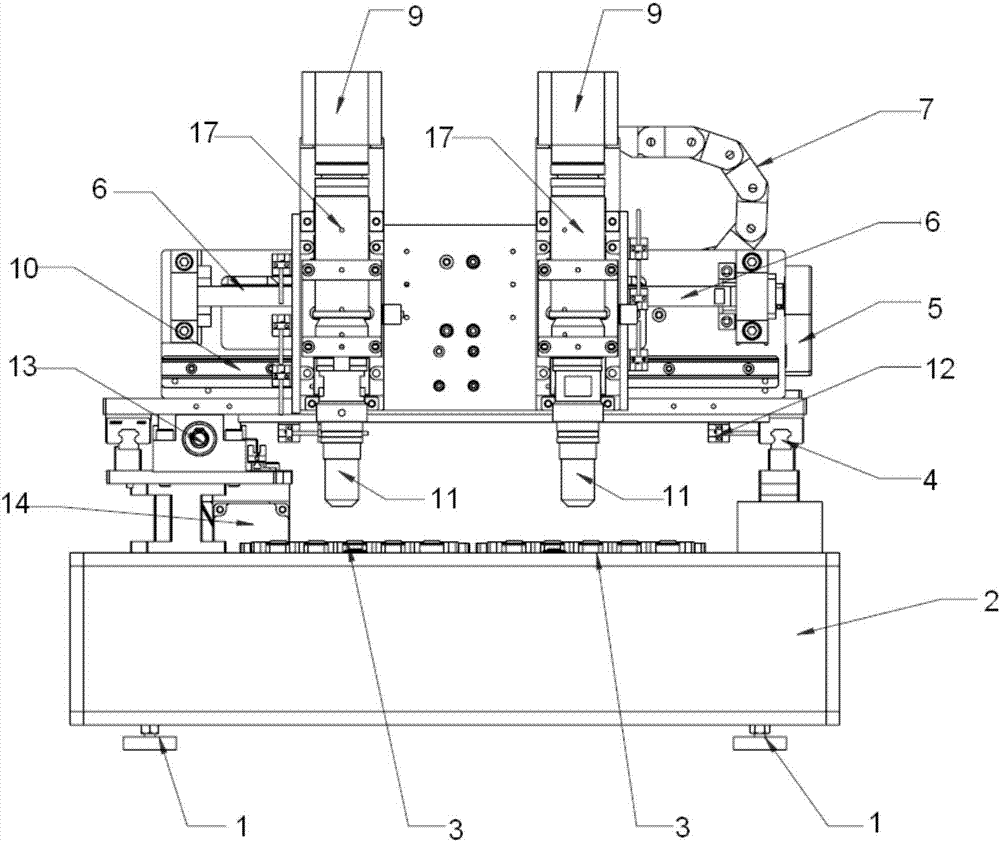

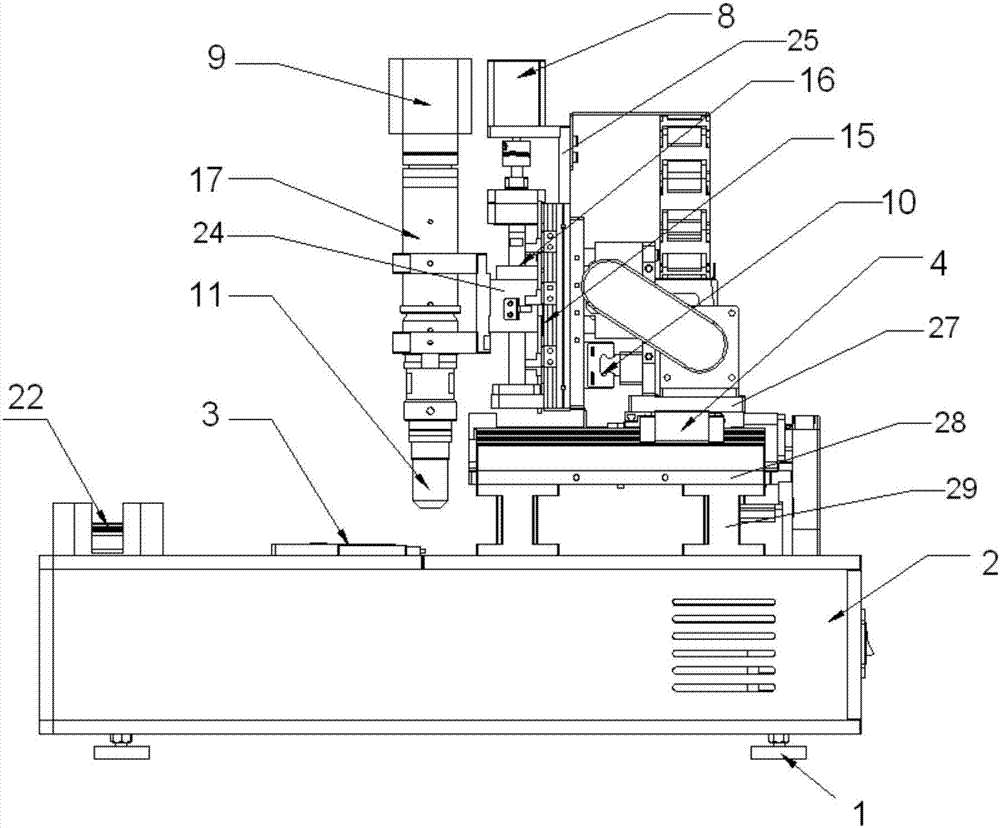

[0042] Refer to attached Figures 1 to 4 As shown, the fully automatic microscopic scanner in this embodiment includes an image acquisition mechanism 9 , a microscopic scanning mechanism, an object loading platform mechanism 3 and a light source mechanism 15 arranged in sequence from top to bottom. The micro scanning mechanism includes an adjustable optical lens barrel 17 and a replaceable lens 11, the image acquisition mechanism 9 is connected with the lens barrel 17, the lens 11 is positioned above the object-carrying platform mechanism 3, and the light source mechanism 15 is positioned at the object-carrying platform Directly below body 3.

[0043] In the present invention, the object-carrying platform mechanism 3 and the light source mechanism 15 are fixedly arranged, and the microscopic scanning mechanism and the image acquisition mechanism 9 can realize movement in the X-axis, Y-axis, and Z-axis directions under the action of the power control mechanism, that is, realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com