Horizontal pneumatic optical effect simulation device

A technology of aero-optics and simulation devices, applied in the field of aero-optics, can solve problems that are not directly simulated, achieve uniform airflow, improve simulation effects, and facilitate miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

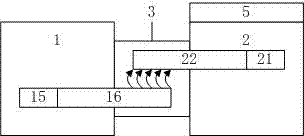

[0030] The horizontal aero-optical effect simulator of this embodiment has a schematic structural diagram as shown in figure 1 shown. The horizontal aero-optical effect simulation device includes a black body 1 and a tank body 2 arranged in sequence horizontally, the opening of the black body 1 is opposite to the opening of the tank body 2, and the black body 1 and the tank body 2 are connected through a connecting structure 3;

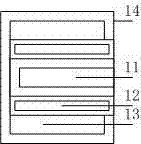

[0031] The black body 1 includes a ceramic layer 11, an intermediate layer 12, a cooling layer 13 and an outer shell 14 from the inside to the outside; the middle layer 12 is provided with a resistance wire, and the inner wall is provided with a temperature sensor, and the cooling layer 13 is filled with water. ; The schematic diagram of the structure of Heibody 1 is as follows: figure 2 shown;

[0032] The top of the tank body 2 is provided with an opening, and a cover 5 is provided on the opening;

[0033] A first air pump 15 is also arranged in...

specific Embodiment 2

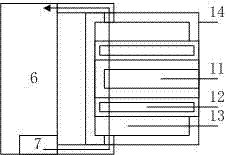

[0037] The horizontal aero-optical effect simulation device of this embodiment is further defined on the basis of the specific embodiment 1 to include a water tank 6 and a water pump 7. The top and bottom of the cooling layer 13 each have an outlet, and the water pump 7 pumps the water tank 6 The water pumped into the outlet at the bottom of the cooling layer 13, and the water flows back to the water tank from the outlet at the top of the cooling layer 13, such as image 3 shown.

[0038] This structural design, utilizing the slow thermal conductivity of water, not only realizes the heat preservation of the ceramic layer 11 and the middle layer 12, ensures the stability of the aero-optical effect simulated by the aero-optical effect simulation device, but also realizes the cooling of the outer shell 14, Ensure experimental safety.

specific Embodiment 3

[0040] The horizontal aero-optical effect simulation device of this embodiment, on the basis of the specific embodiment 1, further defines that the cover 5 is a furnace ring structure, including a plurality of annular rings with different diameters, nested in sequence, and with a stepped cross-section. Such as Figure 4 as shown, Figure 4 Shown is a schematic diagram of the superposition of three annular rings and the structure of the furnace ring after the superposition.

[0041] This structural design can adjust the opening size of the cover 5 by adjusting the number of annular rings, and then change the simulation effect of the aero-optical effect without changing other structures, parameters and technical indicators, thereby increasing the aero-optical effect of the present invention. The simulation range of the effect simulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com