Inkjet recording method and inkjet recording medium

An inkjet recording method, inkjet recording medium technology, applied in the direction of copying/marking method, ink, coating, etc., can solve the problems of time-consuming, poor fixability, slow absorption of liquid components, etc., and achieve excellent dryness, high ink The effect of liquid discharge and high printing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0243] Hereinafter, the present invention will be more specifically described using examples and the like. In the following examples and the like, various physical properties were measured by the following methods. In addition, "parts" and "%" are "parts by mass" and "% by mass" unless otherwise indicated.

[0244] (1) Determination of the weight-average molecular weight of the water-insoluble polymer

[0245] With N,N-dimethylformamide respectively according to the concentration of 60mmol / L and 50mmol / L dissolved in the solution of phosphoric acid and lithium bromide as the eluent, using gel permeation chromatography [GPA device manufactured by Tosoh Co., Ltd. ( HLA-8120GPA), Tosoh Corporation column (TSK-GEL, α-M×2 pieces), flow rate: 1 mL / min] The molecular weight of the water-insoluble polymer was measured. In addition, as a standard substance, the monodisperse polystyrene of known molecular weight was used.

[0246] (2) Determination of solid content concentration of a...

manufacture example I

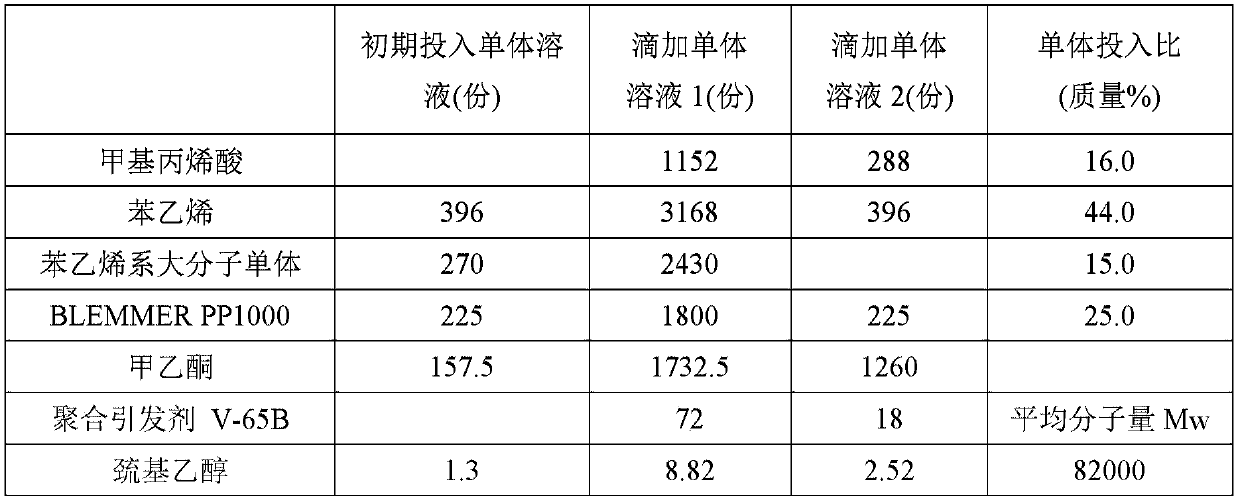

[0253] Production example 1 (production of water-insoluble polymer (a-1) solution)

[0254] In the reaction vessel that possesses 2 dropping funnels 1 and 2, add the monomer, solvent, polymerization initiator (2,2'-azobis(2,4 -Dimethylvaleronitrile)) (manufactured by Wako Pure Chemical Industries, Ltd., trade name: V-65B) and polymer chain transfer agent (2-mercaptoethanol) (manufactured by Kishida Chemical Co., Ltd.) were mixed and replaced with nitrogen to obtain Initially put into the monomer solution.

[0255] Next, the monomer, solvent, polymerization initiator, and polymerization chain transfer agent shown in the "dropping monomer solution 1" of Table 1 are mixed to obtain the dropping monomer solution 1, which is added to the dropping funnel 1, Nitrogen replacement was performed. In addition, the monomer, solvent, polymerization initiator, and polymerization chain transfer agent shown in the "dropping monomer solution 2" of Table 1 were mixed to obtain the dropping mo...

manufacture example II

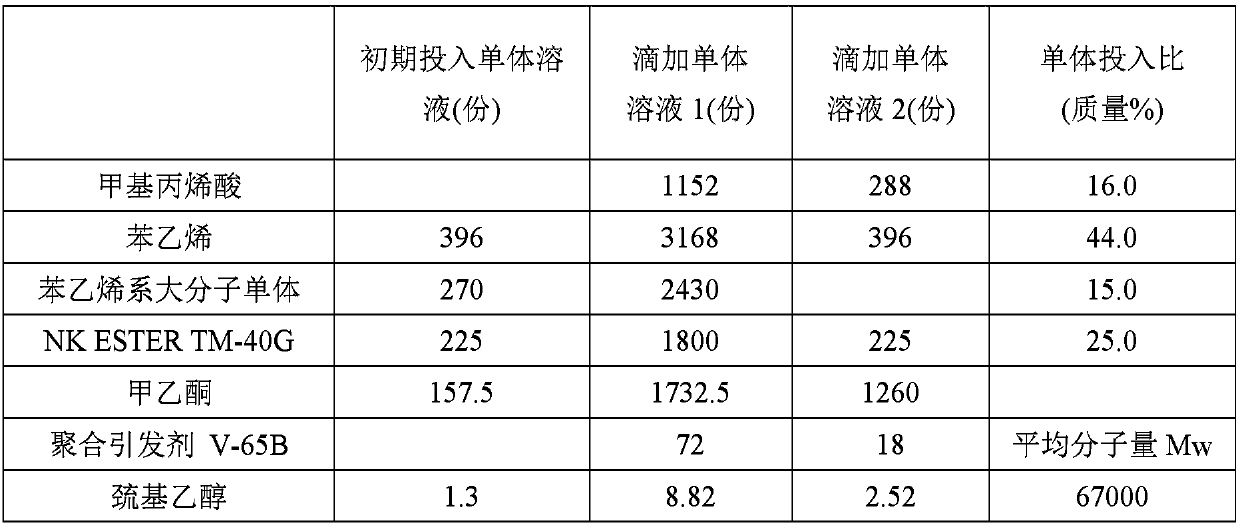

[0263]Production example II (production of water-insoluble polymer a-2 solution)

[0264] In the "Initial Input Monomer Solution" described in Table 1 of Production Example 1 above, except that BLEMMER PP1000 was replaced by NKESTER TM-40G, water was obtained as shown in Table 2 according to the production method described in Production Example 1. Insoluble polymer (a-2) solution (polymer solid content concentration: 36%). The weight average molecular weight of the water-insoluble polymer (a-2) was 67,000.

[0265] 【Table 2】

[0266]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap