Valve device for a motor vehicle

A valve device, motor vehicle technology, applied in valve devices, machines/engines, lift valves, etc., can solve problems such as increased cost and complex shell design, and achieve the effects of reducing the risk of damage, high adjustment quality, and increased sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

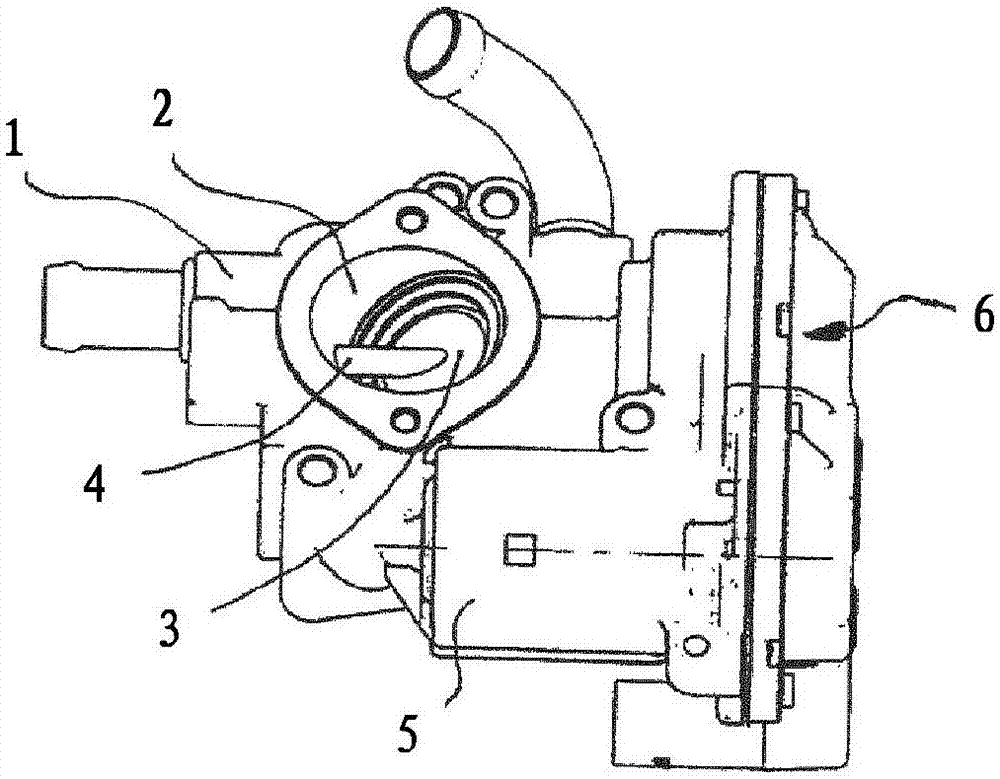

[0024] figure 1 The figure shows a throttle nozzle as a valve arrangement, with a housing 1 , a flow channel 2 in the housing, in which a disk-shaped flap 3 is arranged. The valve flap 3 is fixedly connected to a shaft 4 and the shaft 4 is rotatably mounted in the housing 1 . The electric motor 5 drives the shaft 4 via a transmission 6 .

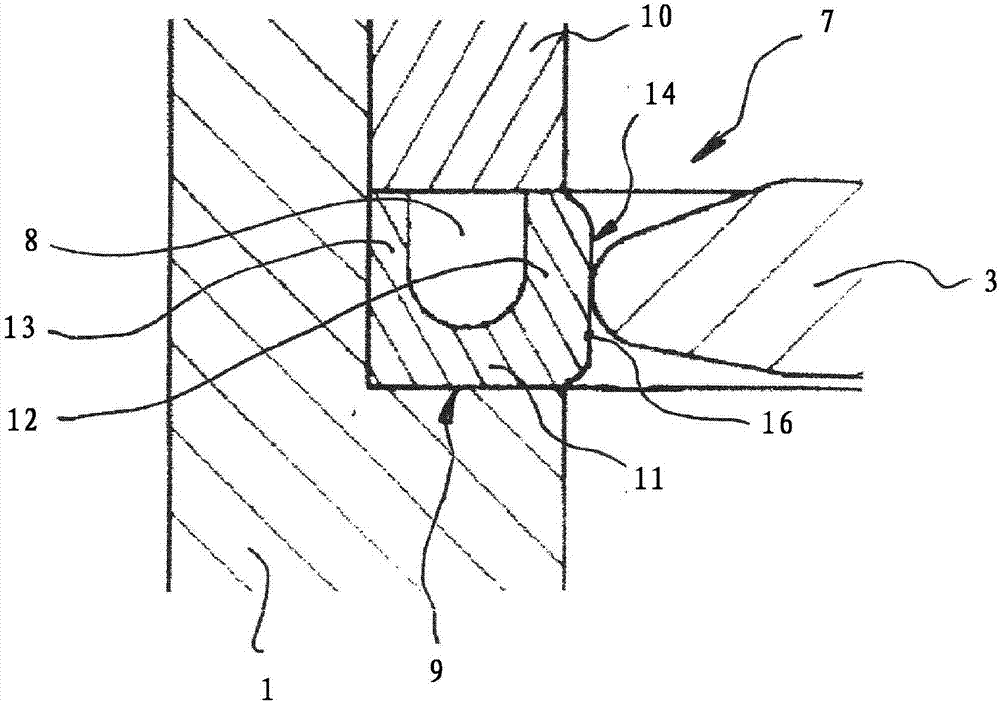

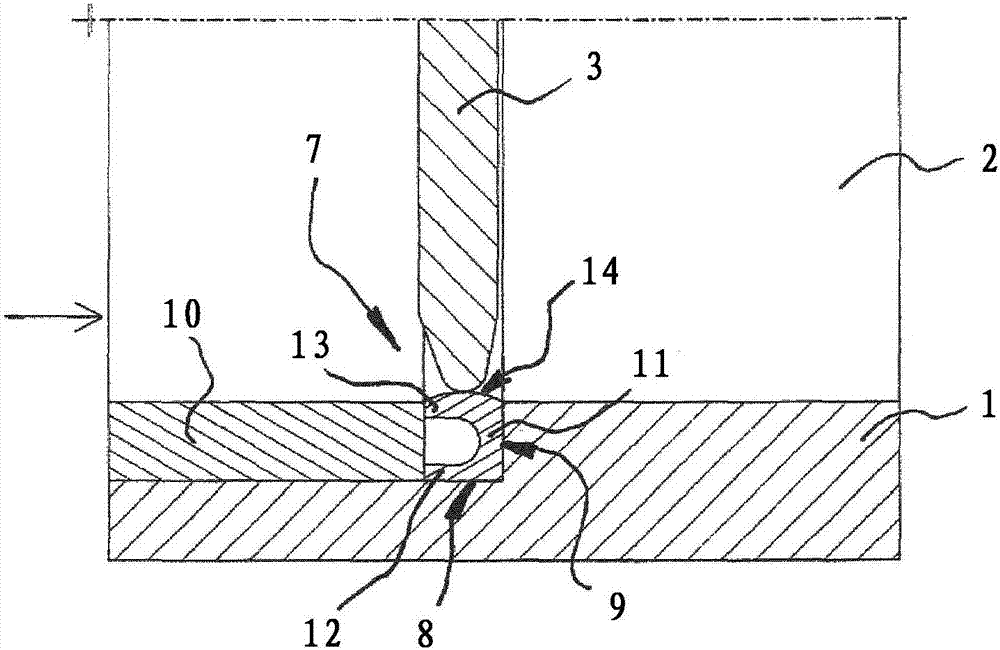

[0025] The cylindrical region in which the valve flap 3 seals the flow channel 2 is the valve seat 7 . The direction of flow in flow channel 2 is indicated by arrows. figure 2 The flap 3 is shown in the closed position in the flow channel 2 . For this purpose, the valve flap 3 bears against the seal 8 . The seal 8 rests against a shoulder of the flow channel 2 designed as a receptacle 9 and is held in this position by a locking ring 10 . The seal 8 has a U-shaped cross-section, wherein the corner top 11 and the leg 12 of the seal 8 rest on the shoulder 9 , and the leg 13 is in contact with the valve flap 3 . The leg 13 facing the flap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com