Magneto-mechanical resonator sensor with absorption material

A resonator, receiver technology used in the analysis of materials, the use of mechanical devices, the use of sonic emission technology for material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] MMR Sensor Assembly - Patterned Capillary Action Rope

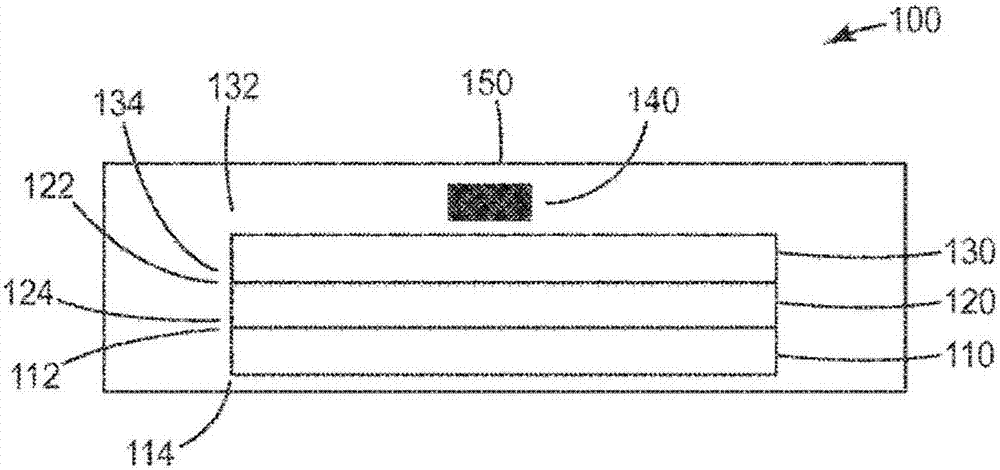

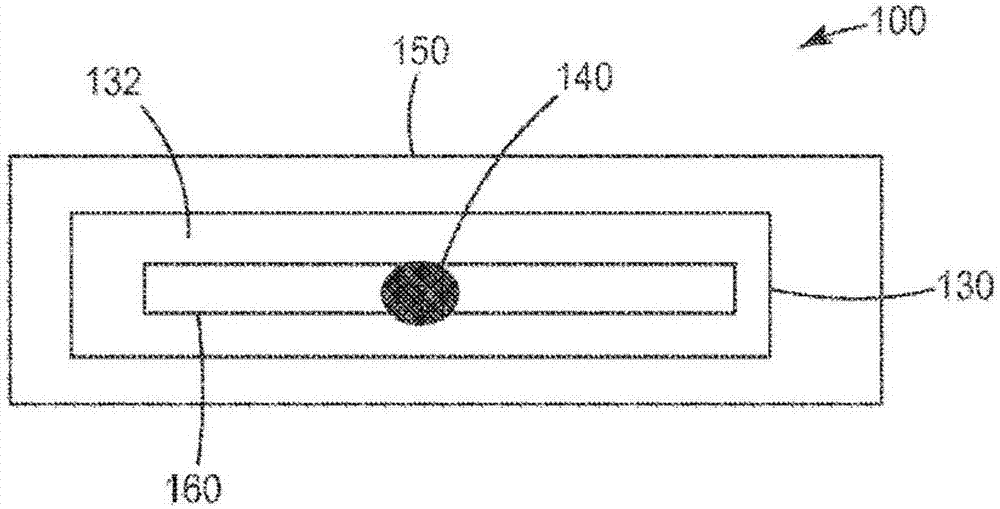

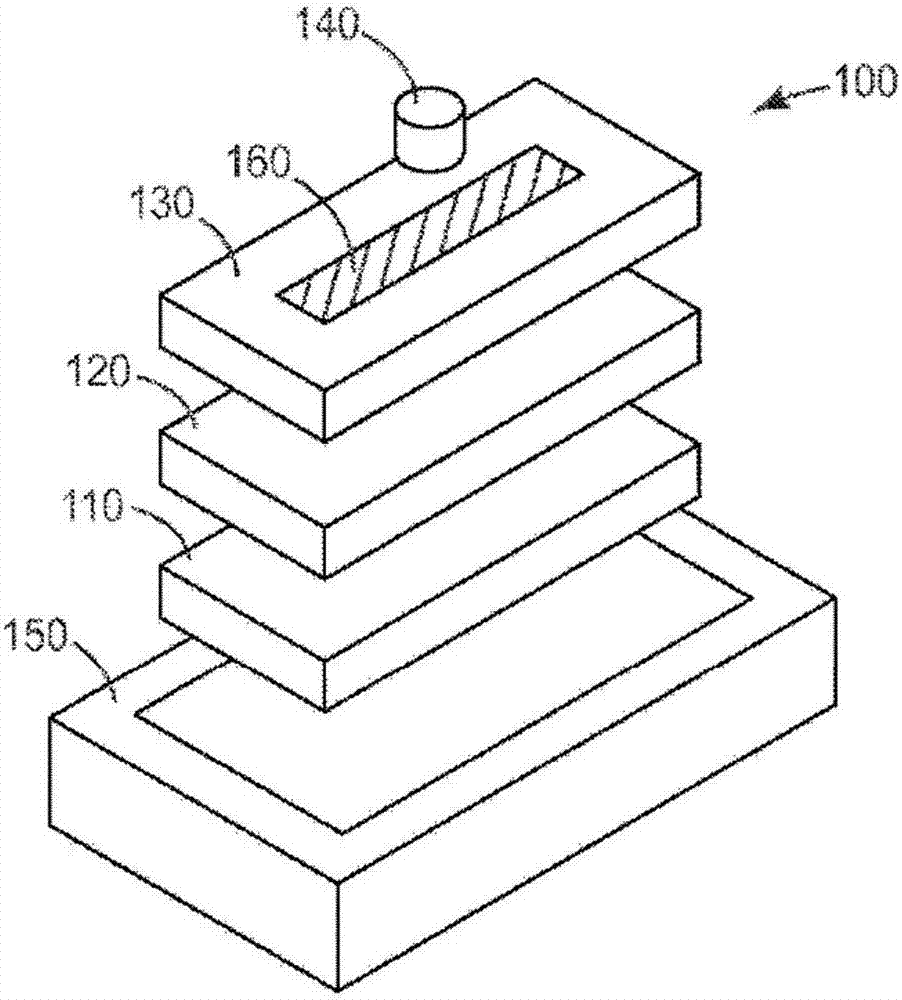

[0121] refer to Figure 1A As well as the change of the position of the environmental change receiver 140, the MMR sensor 100 is assembled in the following manner. Channel 160 is created on first resonator major surface 132 of resonator 130 using physical techniques. A 3.5 cm (1.4 inch) long and 4.7E-2 cm (1.9E-2 inch) diameter tube obtained from Excell Mills, Inc., Mount Holly, NC, USA was used. Capillary action ropes to create channels 160 . by Figure 4B The pattern was adhered to the long axis of the first resonator major surface 132 with Scotch 467MP adhesive from 3M Company, St Paul, MN. Selected from Conway, South Carolina, USA company( of Conway, South Carolina) with a size of 3.7cm (1.5 inches) × 6.2E-1cm (2.4E-1 inches) × 3.0E-3mm (1.2E-3 inches) 2826MB magnetic alloy ( 2826MB Magnetic Alloy) to manufacture the resonator 130. Spacer 120 with dimensions 3.7cm (1.5 inches) x 6.2E-lcm (2.4E-1 i...

Embodiment 3

[0128] MMR Sensor Components - Patterned Wicking Paper

[0129] refer to Figure 1A As well as the change of the position of the environmental change receiver 140, the MMR sensor 100 is assembled in the following manner. Channel 160 is created on first resonator major surface 132 of resonator 130 using physical techniques. Using multiple sheets of 3.7cm (1.5 inches) x 3.6E-1 to 4.1E-1cm (1.4E-1 to 1.6E-1 inches) x 2.0E-2cm (7.9E-3 inches) from St. Paul, Minnesota, USA Channel 160 was created with Nexcare First Aid Gentile Paper Tape obtained from 3M Company, St. Paul, MN. by Figure 4B The described pattern adheres the wicking paper to the long axis of the first resonator major surface 132 . Selected from Conway, South Carolina, USA company( of Conway, South Carolina) obtained Metglas measuring 3.7 cm (1.5 in) x 6.2E-1 cm (2.4E-1 in) x 3.0E-3 cm (1.2E-3 in) TM 2826MB magnetic alloy (Metglas TM 2826MB Magnetic Alloy) to manufacture the resonator 130. Spacer 120 wi...

Embodiment 6

[0136] MMR Sensor Components - Digital Cleaning

[0137] refer to Figure 1A As well as the change of the position of the environmental change receiver 140, the MMR sensor 100 is assembled in the following manner. A resonator 130 with a size of 3.7cm (1.5 inches) × 6.2E-1cm (2.4E-1 inches) × 3.0E-3cm (1.2E-3 inches) 2826 magnetic alloy ( 2826 Magnetic Alloy) was commercially available from Conway, South Carolina, USA. Spacer 120 with dimensions 3.7 cm (1.5 inches) x 6.2E-1 cm (2.4E-1 inches) x 1.0E-2 cm (3.9E-3 inches) is constructed of acrylonitrile butadiene styrene (ABS), The ABS was obtained from Plastics International, Eden Prairie, MN. Spacers 120 are accommodated by a magnetic bias layer 110 commercially available as ArnoKrome™ III from The Arnold Engineering Company of Marengo, Illinois, USA, measuring 2.77 cm ( 1.09 inches) x 6.0E-1cm (2.4E-1 inches) x 6.0E-3cm (2.4E-3 inches). Housing 150 enclosing the three layers of magnetic bias 110, spacer 120, and reson...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com