A vertical eddy current sorting device

An eddy current sorting, vertical technology, applied in the field of machinery, can solve the problems of unfavorable material separation, large device volume, short action time, etc., and achieve the effect of reducing belt transmission device, increasing action area, and increasing action time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

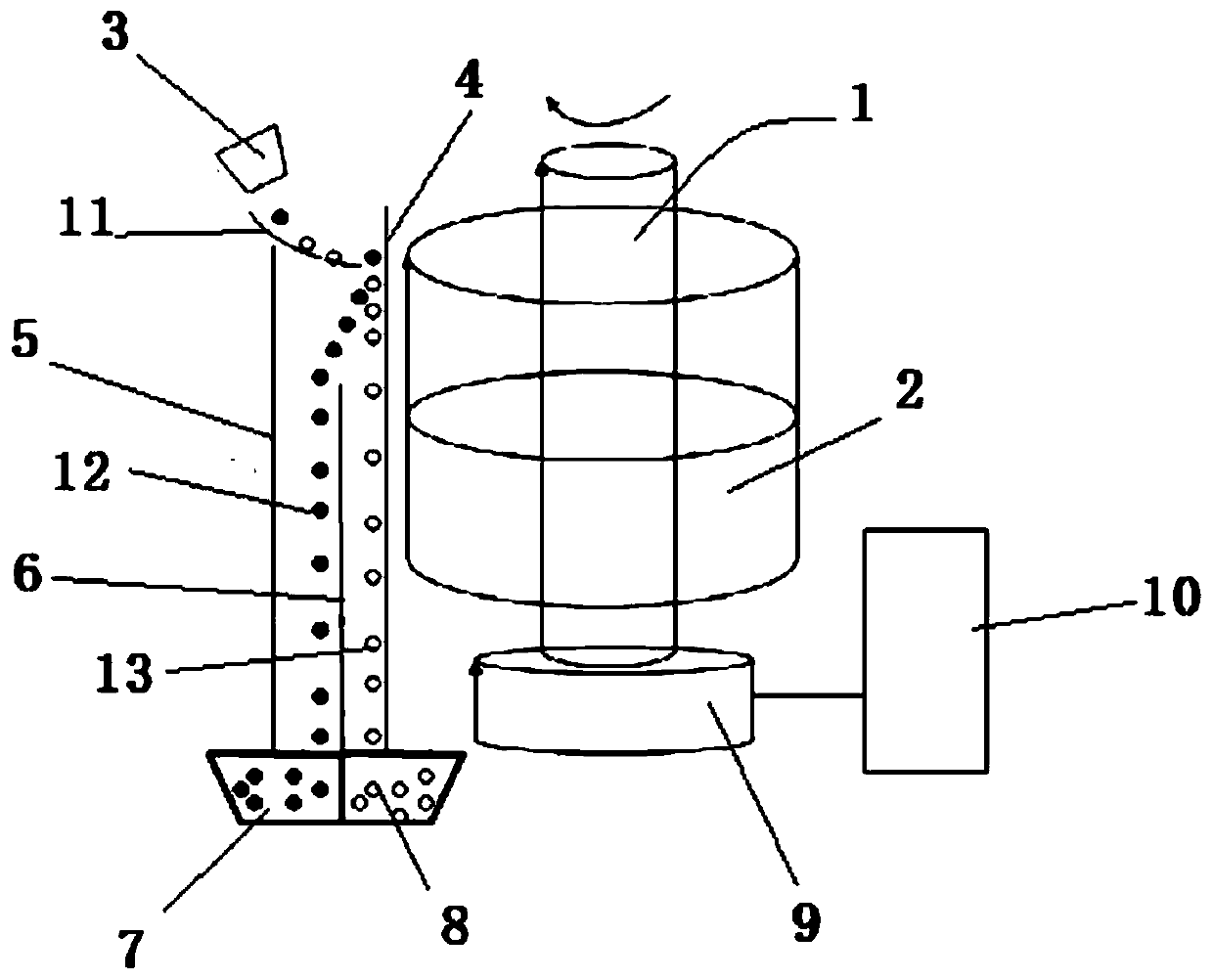

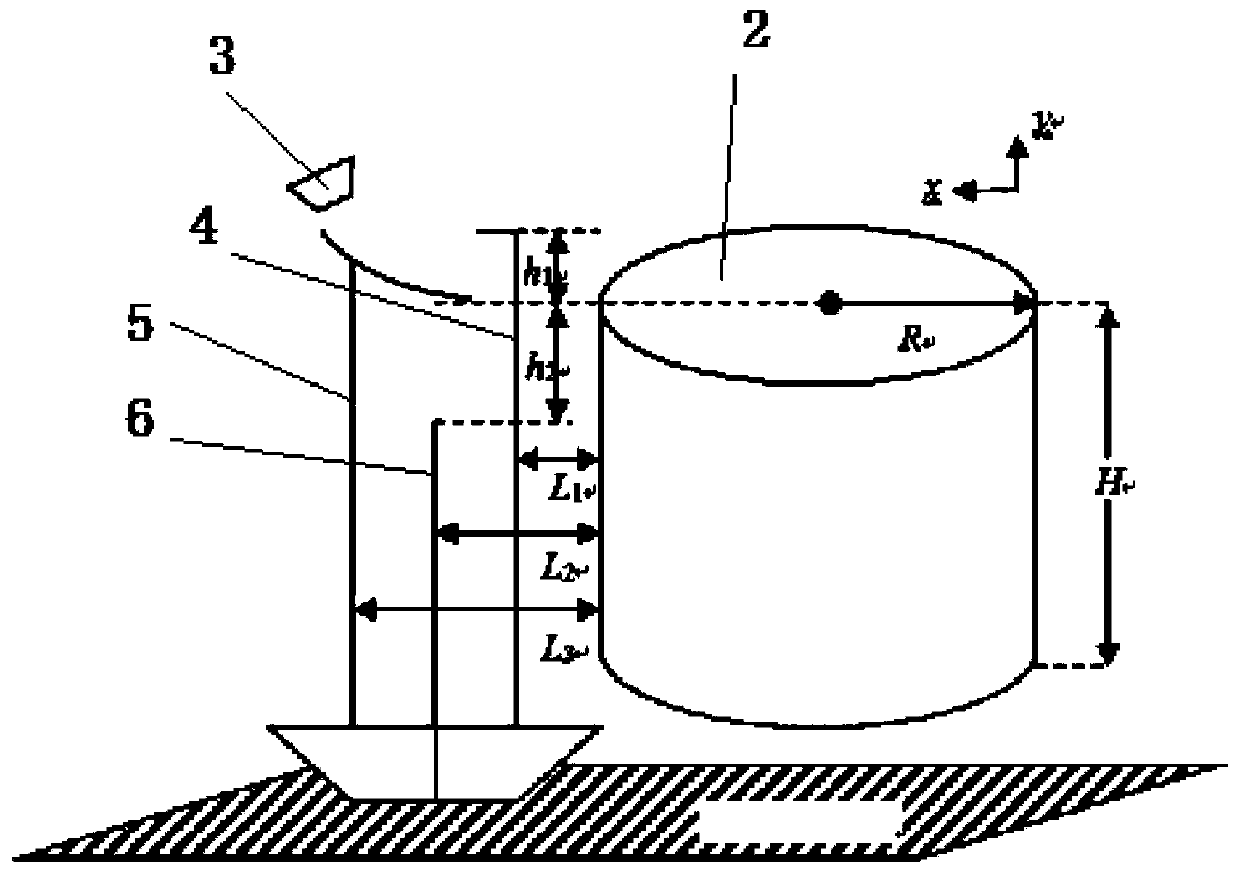

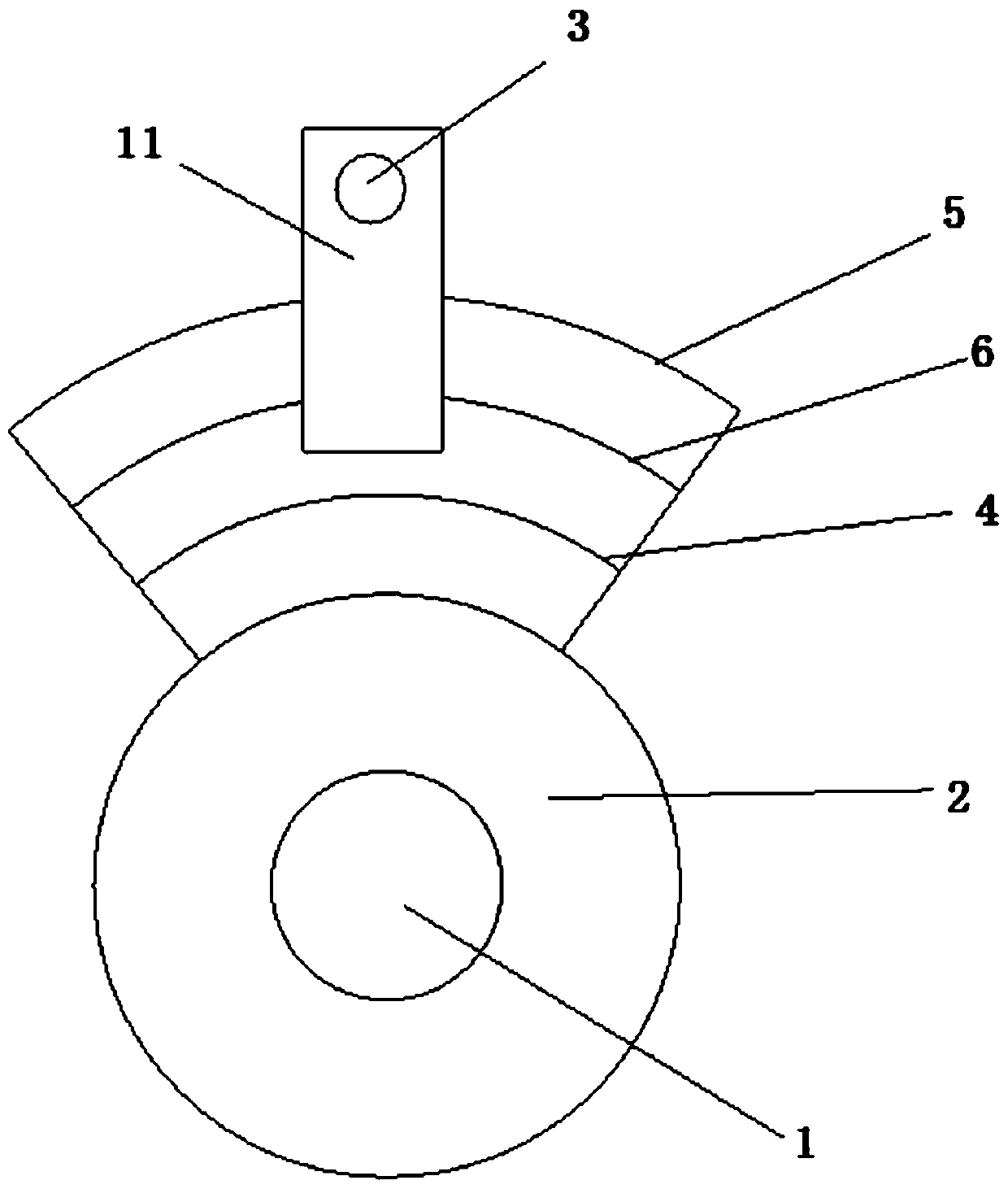

[0041] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1As shown, the present invention includes a rotating shaft 1 arranged in a vertical direction, a magnetic roller 2 is fixed on the rotating shaft 1, and a rotating shaft driving device is arranged below the rotating shaft 1. The rotating shaft driving device includes a motor 9 and a control box 10, and a control chip is arranged in the control box. To control each electrical component; the outside of the magnetic roller 2 is provided with a separation device, which includes an inner separation plate 4, an outer separation plate 5 and a separation plate 6 arranged in a vertical direction, and a feed inlet is arranged above the outer separation plate 5 3. An arc-shaped plate 11 is set under the feed port 3, one end of the arc-shaped plate 11 is set under the feed port 3, and the other end is set between the partition plate 6 and the inner separation plate 4; the arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com