Punching die for processing oil storage barrel

A technology of oil storage tanks and dies, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increasing production costs, reducing production efficiency, and heavy labor, and achieves reducing labor intensity, improving processing efficiency, The effect of quick separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

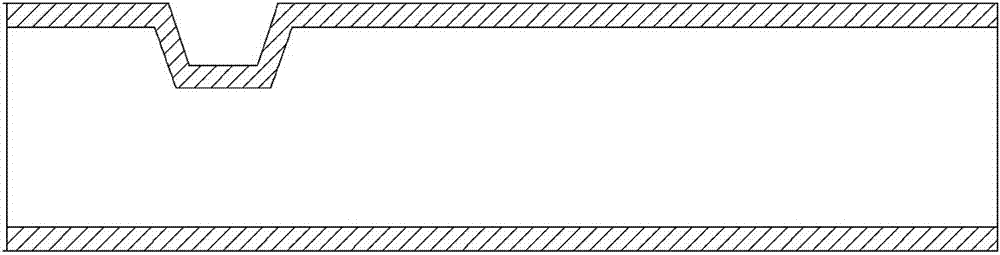

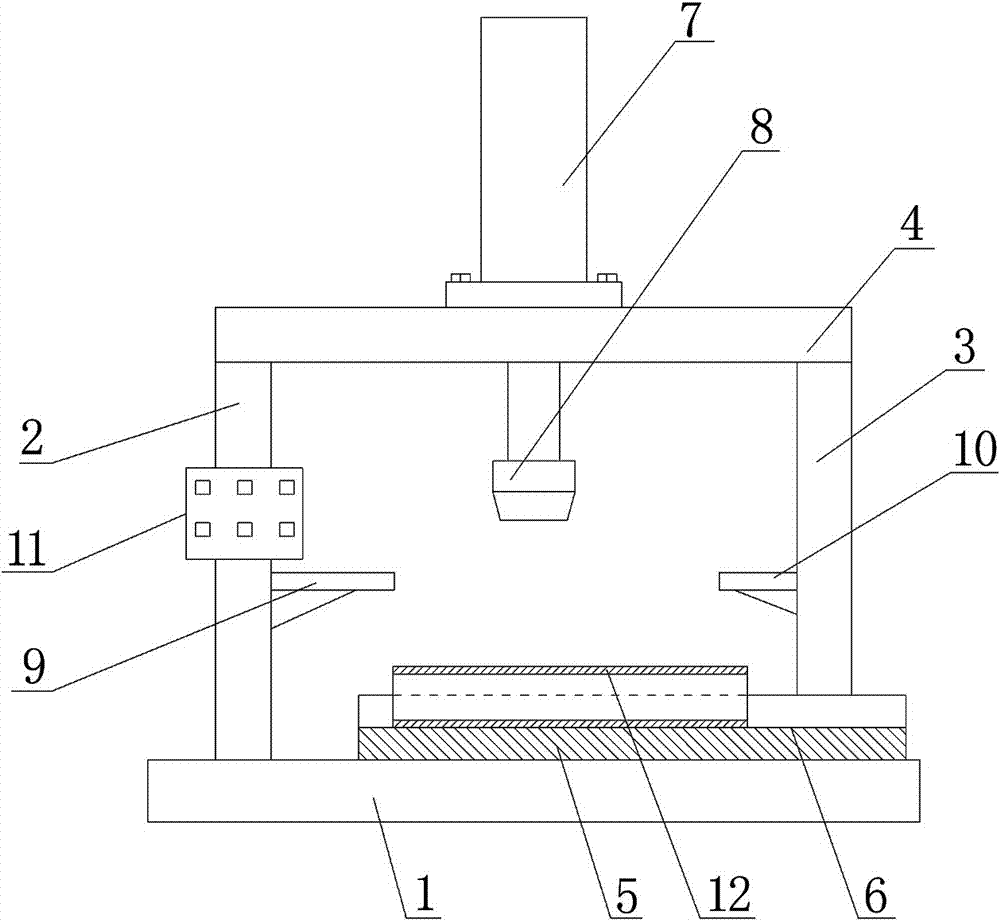

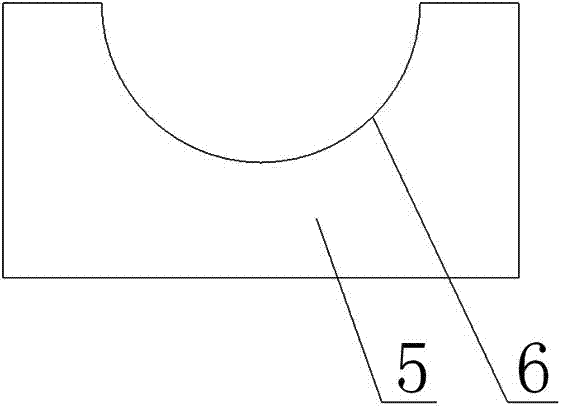

[0017] Such as Figure 2~3 As shown, a punching die for processing an oil storage tank includes a workbench 1, a column A2 and a column B3 arranged on the workbench 1, the column A2 and the column B3 are arranged perpendicular to the workbench 1, and the distance between the column A2 and the column B3 is A crossbeam 4 is arranged between them, and the workbench 1 is provided with a bearing platform 5 below the beam 4. The top of the bearing platform 5 is provided with a semicircular groove 6 matching the shape of the blank, and the blank can be placed in the semicircular groove. 6, the right end of the carrying platform 5 extends outside the column B3.

[0018] Also fixedly installed on the crossbeam 4 is a vertically arranged hydraulic cylinder 7, the piston rod of the hydraulic cylinder 7 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com