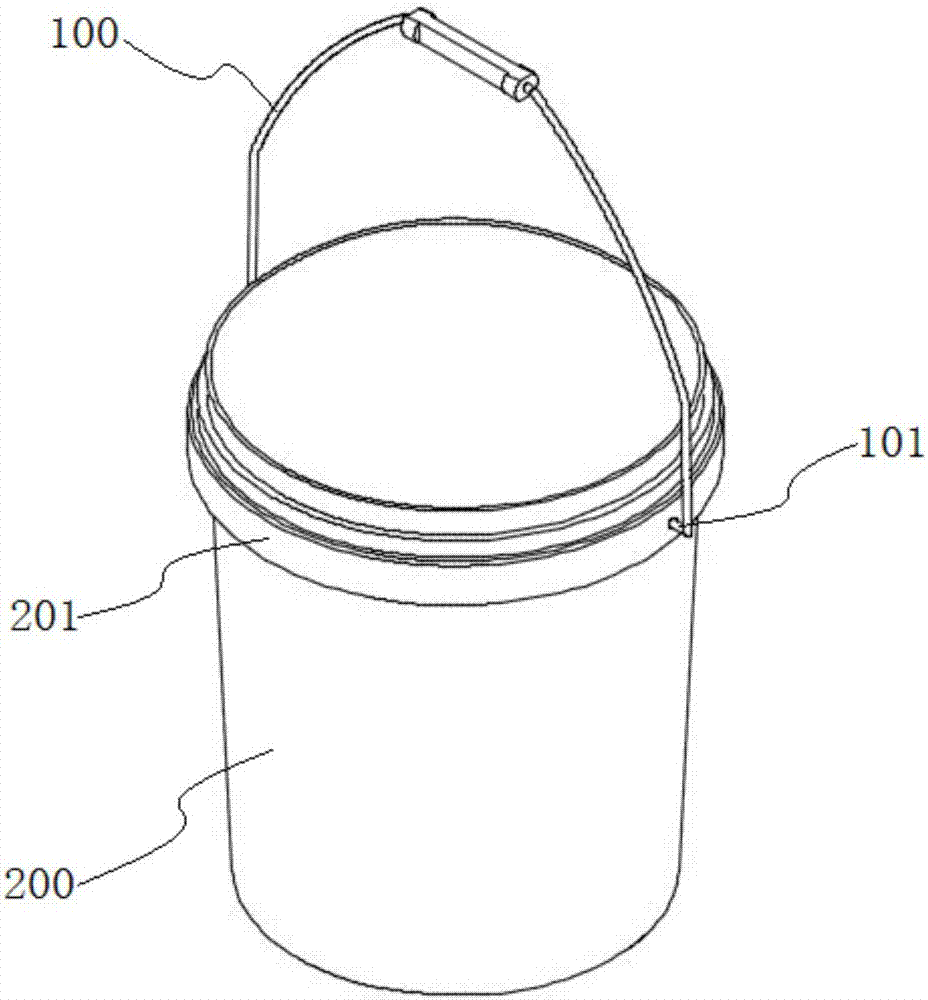

Positioning assembling device for barrel handle and container barrel

A technology of assembling device and positioning device, applied in workpiece clamping device, metal processing, metal processing equipment and other directions, can solve problems such as not simple, and achieve the effect of improving accuracy and success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

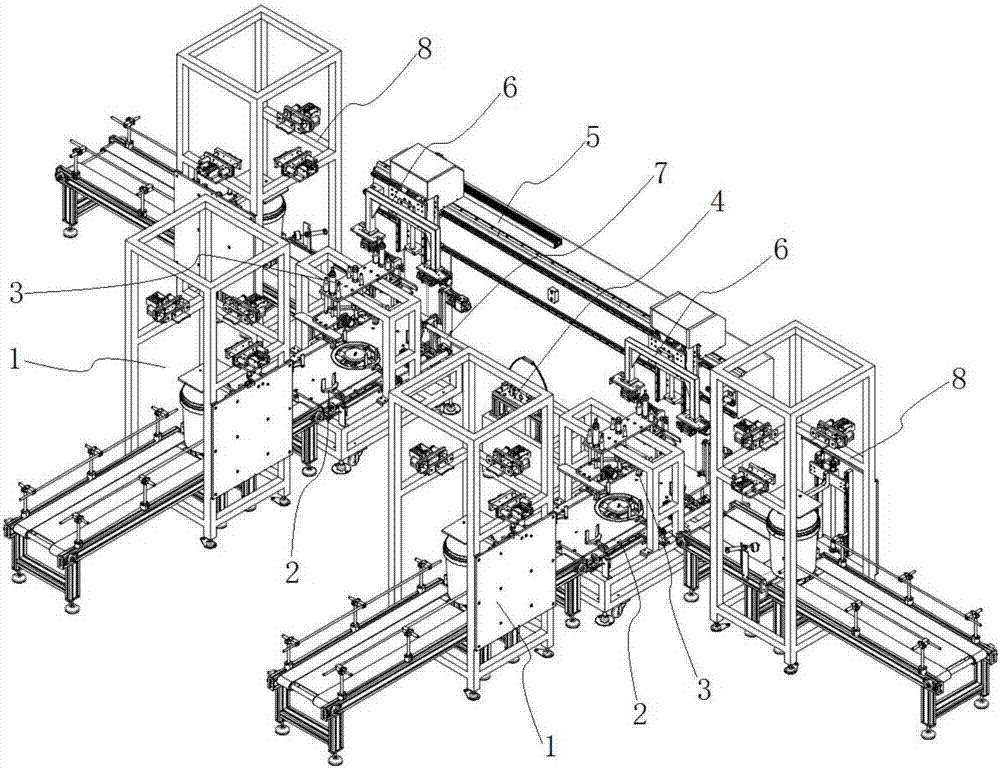

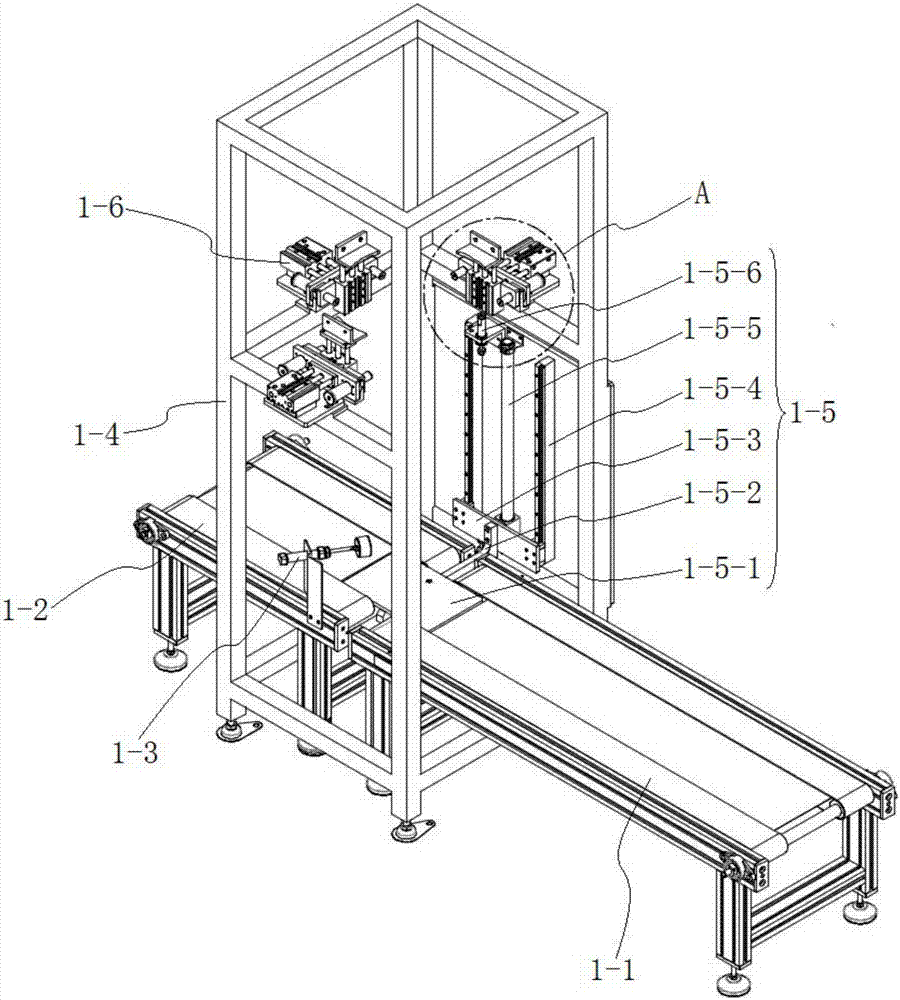

[0055] combine figure 2 As shown, the automatic assembly line of a barrel handle and container barrel in this embodiment includes a container barrel feeding device 1, a container barrel conveying device 2, a container barrel positioning device 3, a barrel handle positioning device 4, and a barrel handle grabbing beam 5. The bucket handle grabbing assembly device 6 and the finished product unloading device 8. The container barrel conveying device 2 has at least a positioning station and a pressing assembly station. The container barrel conveying device 2 is used to move the container barrel from the positioning station to the pressing Tight assembly station conveying; the container barrel feeding device 1 is set before the positioning station of the container barrel conveying device 2, and is used to transport the separated container barrels to the front of the container barrel conveying device 2 one by one, and the container barrel conveying device 2 transported to the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com