A method to enhance the rigidity and self-healing properties of tough hydrogels

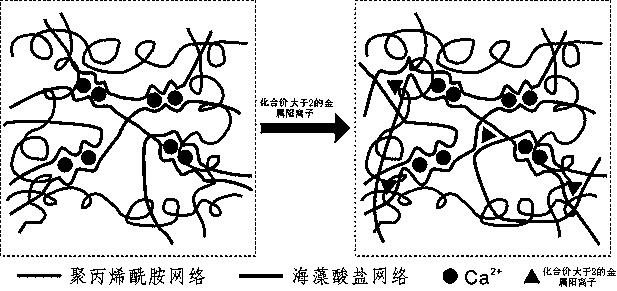

A hydrogel rigidity and hydrogel technology, which is applied in the chemical industry, can solve the problems of non-self-healing, insufficient rigidity and mechanical strength of tough gel, and achieve simple and convenient operation, improved rigidity and mechanical strength, and improved mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

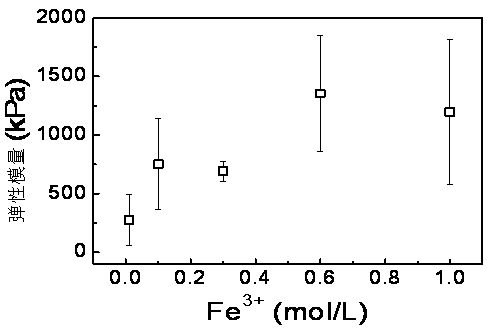

Embodiment 1

[0030] Immerse the stretched bowl-shaped ductile hydrogel in Fe 3+ Concentration is the aqueous solution of 0.05mol / L, and stand for 50min, the flexible hydrogel stretched into the bowl shape becomes the very rigid bowl shape structure. Align the interface of two tough hydrogel fragments and apply 3 drops of Fe 3+ An aqueous solution with a concentration of 0.2 mol / L was applied to the interface and left to stand for 20s. The two tough hydrogel segments were successfully spliced together. The total length after splicing and the sum of the lengths of the two tough hydrogel segments At the same time, the toughness of the spliced flexible hydrogel is very good, stretched to 7 times its own length, and still no fracture occurs, indicating that Fe 3+ The solution enables efficient self-healing of the tough hydrogel.

Embodiment 2

[0032] Immersion of ductile hydrogel stretched into a helical shape in Ni 3+ In an aqueous solution with a concentration of 0.3 mol / L and standing for 20 minutes, the tough hydrogel stretched into a bowl shape becomes a helical structure with very good rigidity. Align the interface of the two tough hydrogel fragments and place 5 drops of Ni 3+ An aqueous solution with a concentration of 0.8mol / L was applied to the interface, and left to stand for 40s. The two tough hydrogel segments were successfully spliced together. The total length after splicing and the sum of the lengths of the two tough hydrogel segments The difference is not big, and at the same time, the toughness of the tough hydrogel after splicing is very good, stretched to 7 times its own length, and no fracture has occurred, indicating that Ni 3+ The solution enables efficient self-healing of the tough hydrogel.

Embodiment 3

[0034] Immerse the tough hydrogel stretched into an L-shape in Mn 4+ In an aqueous solution with a concentration of 1.3 mol / L and standing for 100 min, the tough hydrogel stretched into a bowl shape becomes an L-shaped structure with very good rigidity. Align the interface of the two tough hydrogel fragments and place 4 drops of Mn 4+ An aqueous solution with a concentration of 1.8mol / L was applied to the interface and left to stand for 70s. The two tough hydrogel segments were successfully spliced together. The total length after splicing and the sum of the lengths of the two tough hydrogel segments At the same time, the toughness of the spliced flexible hydrogel is very good, stretched to 7 times its own length, and no fracture occurs, indicating that the Mn 4+ The solution enables efficient self-healing of the tough hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com