A powder spraying machine for alloy workpieces

A powder sprayer and metal workpiece technology, applied in the direction of pressure inorganic powder coating, can solve the problems of low work efficiency, rework, scattered powder, etc., to save labor costs, improve work efficiency, and avoid waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

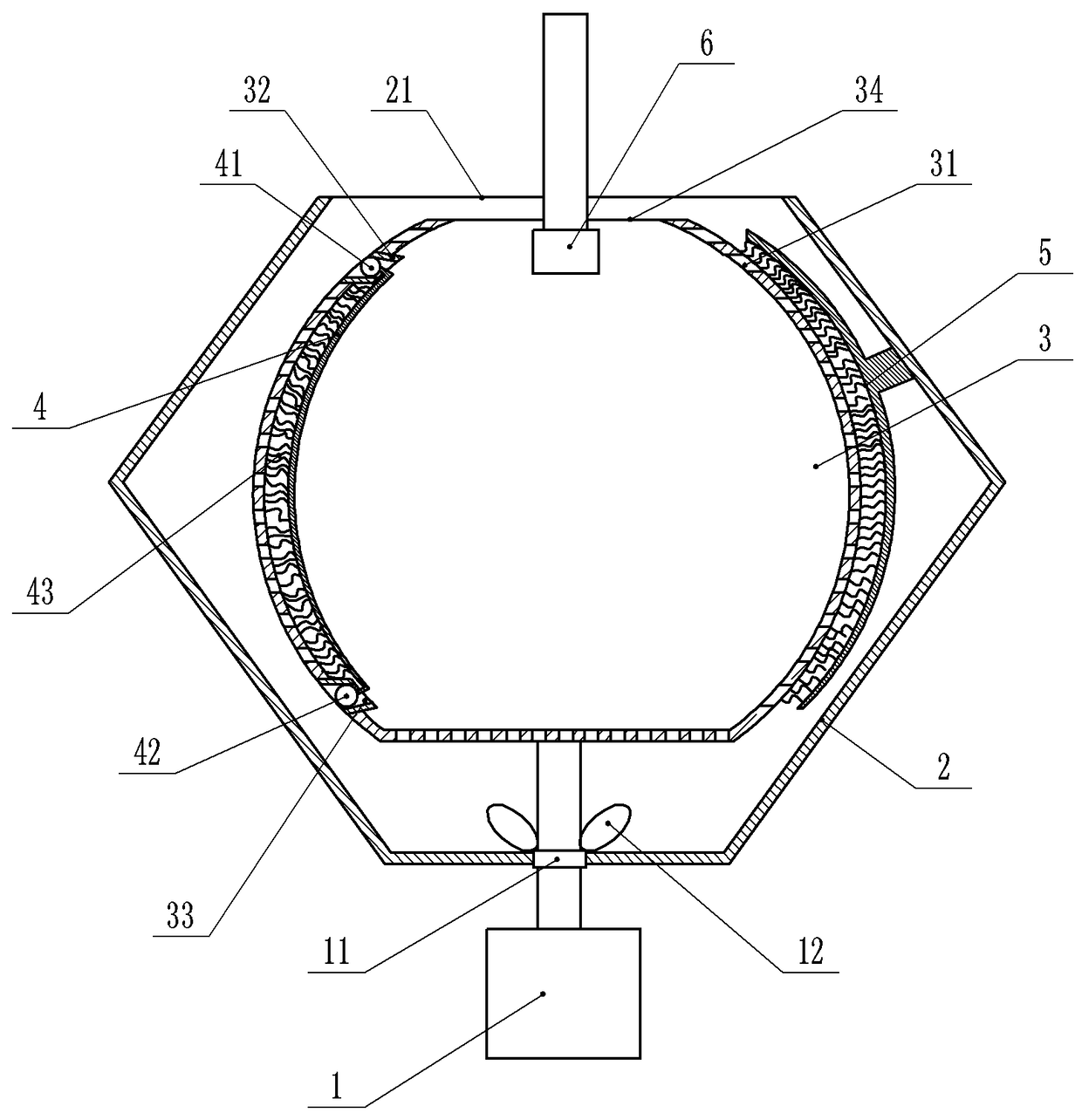

[0018] The reference signs in the accompanying drawings of the specification include: motor 1, bearing 11, blade 12, casing 2, exhaust port 21, liner 3, feed port 31, upper annular groove 32, lower annular groove 33, through hole 34, Brush rod 4, upper ball 41, lower ball 42, bristle 43, brush handle 5, nozzle 6.

[0019] Such as figure 1 As shown, a powder spraying machine for metal workpieces includes a nozzle 6, an inner tank 3, a cleaning brush, a casing 2 and a motor 1 from top to bottom, and the nozzle 6 is used to spray powder coated on the surface of a metal workpiece. The surface of the inner container 3 is provided with a plurality of through holes 34 , and the upper part of the inner container 3 is provided with a feeding port 31 through which metal workpieces are placed in the inner container 3 . The lower part of the housing 2 is conical, and the upper part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com