Novel shell body valve seat for quick connector

A shell and valve seat technology, which is applied in the field of shell valve seats for new quick connectors, can solve problems such as inability to complete non-stop operations, and achieve the effects of good durability, avoiding damage to joints, and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

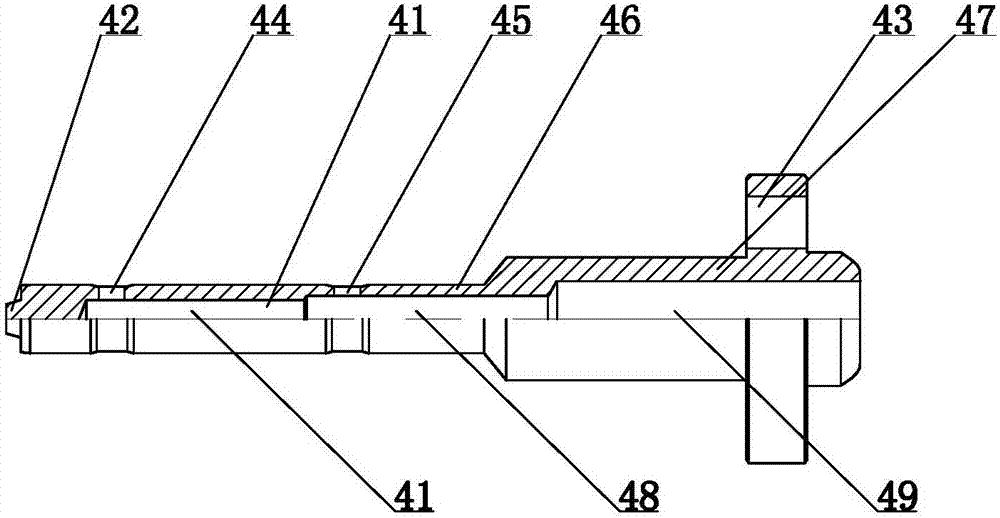

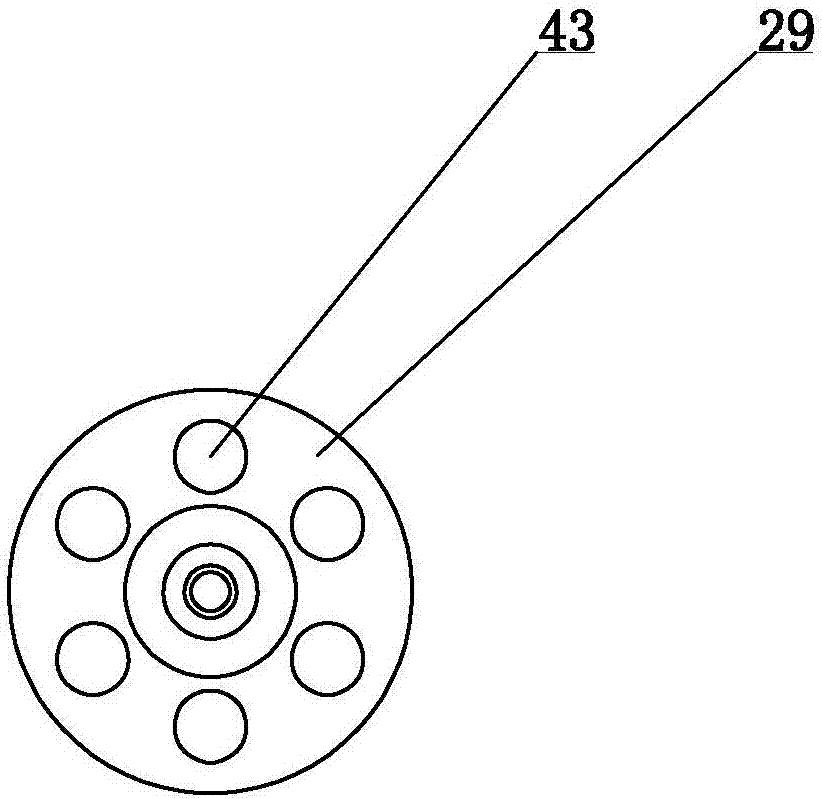

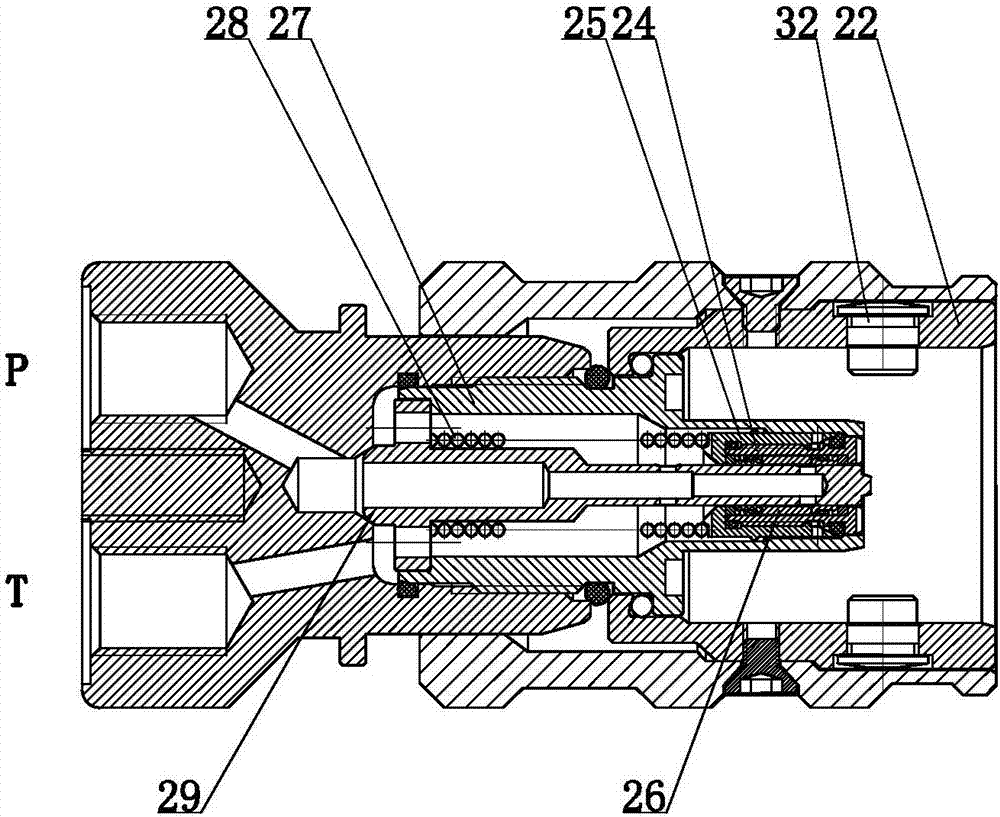

[0012] Such as figure 1 , 2 , 3, 4, and 5 show the housing valve seat for the new quick connector, including the housing valve seat main body 29, the housing valve seat main body 29 including the annular body A46 and the annular body B47, and the annular body A46 and the annular body B47 are integrated Forming, the annular body A46 is in the front, and the outer diameter of the annular body A46 is smaller than the outer diameter of the annular body B47. The hole B45 and the through hole A44 are located in front of the through hole B45, the outer wall of the rear part of the annular body B47 protrudes outwards to form an annular body A, and the annular body A is horizontally provided with a through hole C43, and the annular body A is in contact with the slot, and The inner wall of the through hole C43 is not smaller than the inner wall of the ring body D to avoid the impact and wear of the medium. The rear end of the ring body B47 opens to form a flow channel, which extends to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com