Method for calibrating inertial platform system gyroscope torquer coefficient

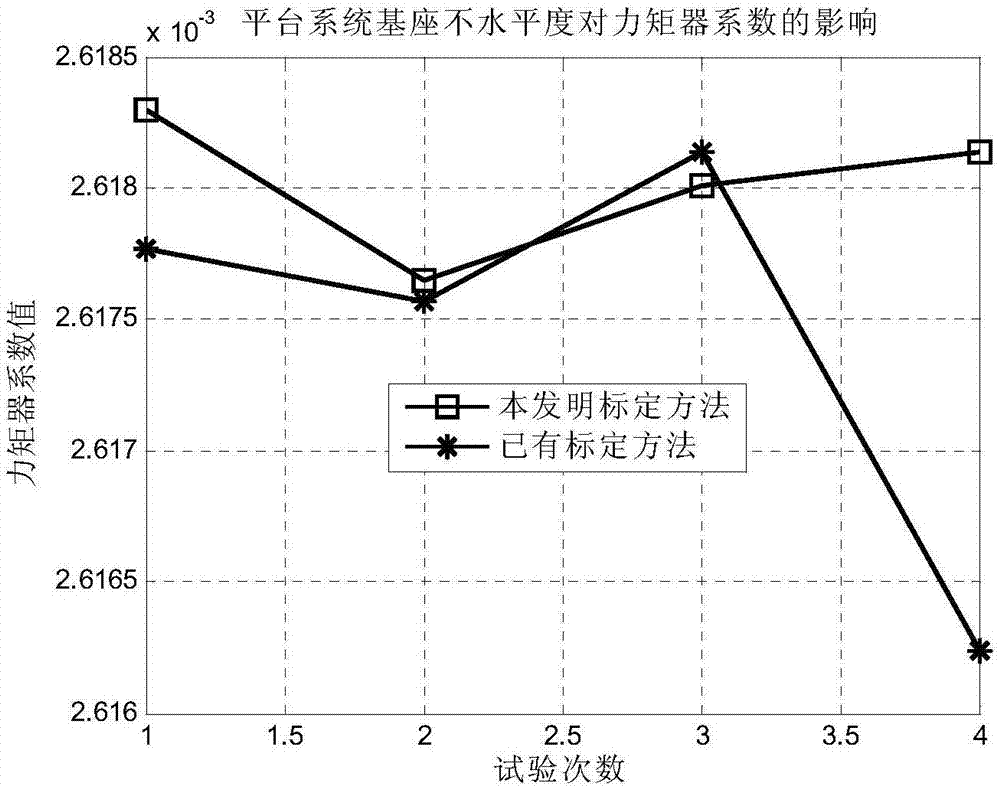

An inertial platform and calibration method technology, which is applied in the field of inertial platform system calibration, can solve the problems of inability to correctly respond to the rotation angle of the vertical gyroscope, high requirements for the levelness of the platform system base, and torque device calibration errors, etc., to improve environmental adaptation Sex, reduce measurement error, reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

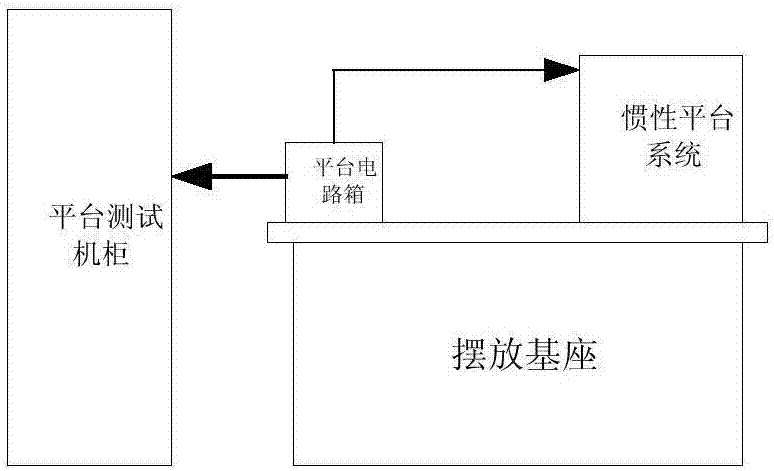

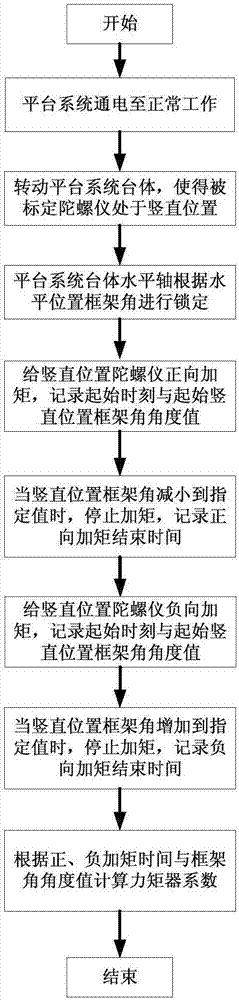

[0021] Such as figure 1 As shown, the inertial platform system torque device calibration system adopted in the present invention includes an inertial platform system 1, a platform circuit box 3, a platform test cabinet 4 and a placement base 2, wherein the inertial platform system 1 includes a table body, a base, Gyroscope and frame angle sensor; the frame angle sensor adopts a dual-channel multi-pole resolver, and the number of pole pairs is generally 32, 64, etc.; place the inertial platform system 1 and the platform circuit box 3 on the placement base 2, and the platform circuit box 3 is connected with the inertial platform system 1, the platform circuit box 3 is used to supply power to the inertial platform system 1 and control and monitor the normal operation of the platform body, the platform test cabinet 4 is connected to the platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com