Corrugated carton forming technology

A corrugated box and forming process technology, applied in papermaking, paper/cardboard containers, machining/deformation, etc., can solve the problems of increased paper consumption, increased carton manufacturing cost, low utilization rate of carton materials, etc., and improved structural strength. , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

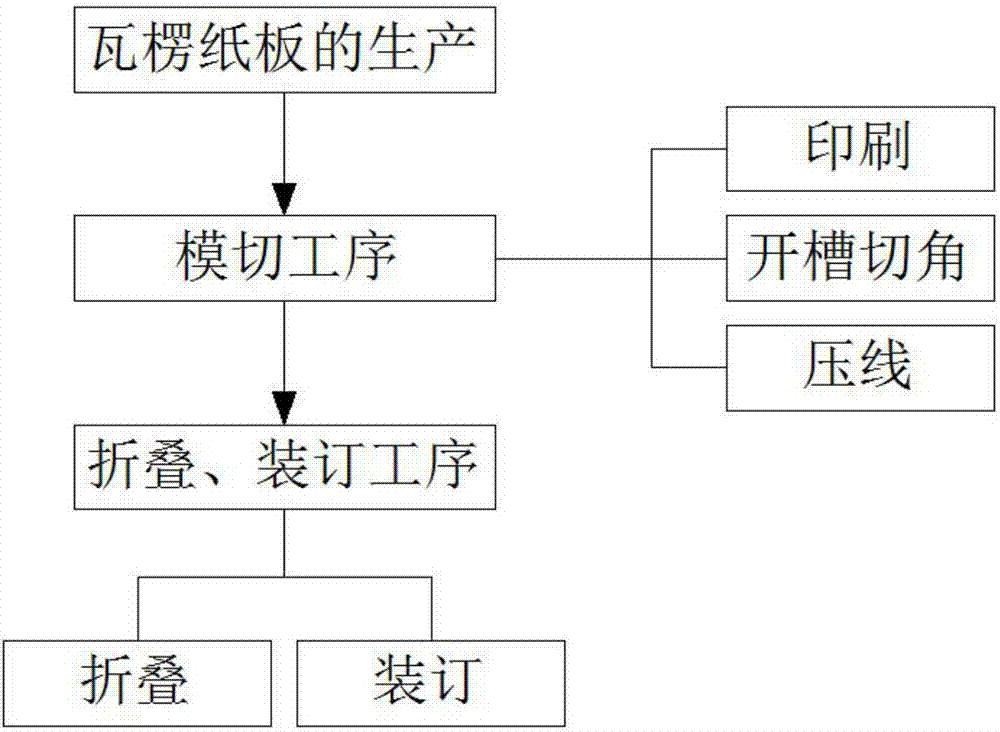

[0018] Example 1: Please refer to figure 1 , the present invention provides a technical solution: a corrugated box molding process, the corrugated box molding process includes the following steps:

[0019] Production of corrugated cardboard: corrugated base paper is corrugated and veneered;

[0020] Die-cutting process: the corrugated cardboard is printed in a predetermined shape, slotted and corner-cut, and crimped;

[0021] Folding and binding process: the corrugated cardboard is glued by folding box gluer and binding machine, and bound into shape.

[0022] Among them, the paper feeding device sends the corrugated cardboard to the printing cylinder and impression cylinder of the flexographic printing device, the printing cylinder prints ink on the surface of the corrugated cardboard, and the protruding part of the impression cylinder embosses the surface of the corrugated cardboard to form Pattern shape, the corner cutting knife and slotting knife are clamped on the corner...

Embodiment 2

[0023] Embodiment 2: This embodiment is further limited on the basis of Embodiment 1. In the die-cutting process, steel knives and steel wires can be installed on the pre-designed template, and the template can be installed on the die-cutting cylinder. The corrugated cardboard sent between the die-cut board and the press board is cut into a predetermined shape and creasing by steel wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com