Fuel storing and conveying assembly achieving low noise

A fuel and component technology, applied in the field of low-noise fuel storage and transportation components, can solve the problems of high shaking noise of automobile fuel tanks and unstable connection between fuel pipes and fuel tanks, and achieves solutions such as excessive shaking noise, prolonging life, reducing The effect of activity gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

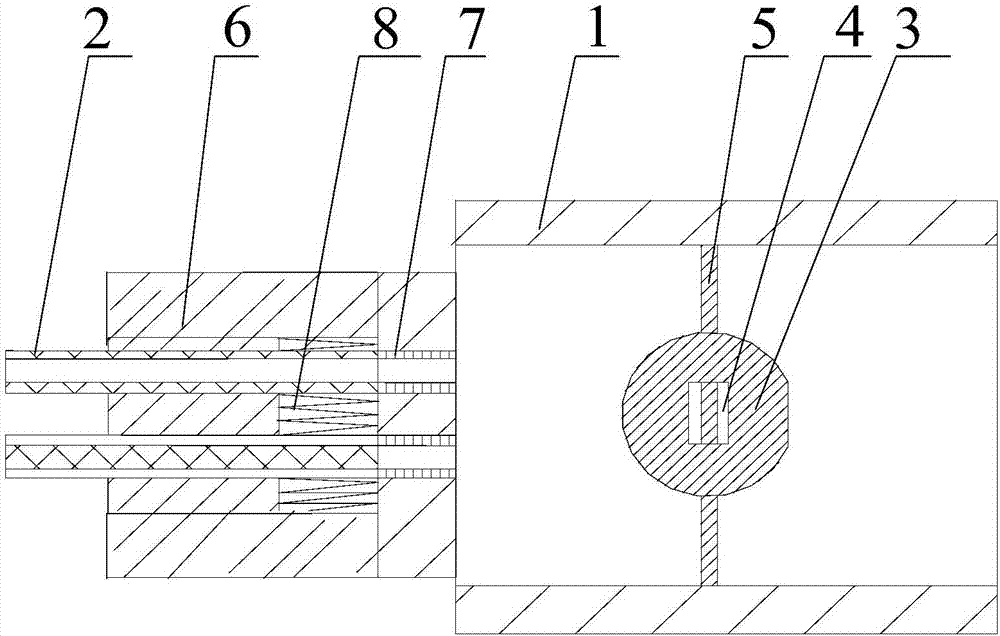

[0020] Such as figure 1 As shown, a low-noise fuel storage and delivery assembly of the present invention includes a fuel tank 1 and a fuel pipe 2. A hollow sphere 3 made of stainless steel is arranged inside the fuel tank 1, and two holes are formed on the surface of the hollow sphere 3. A diversion port 4, the diversion port 4 communicates with the hollow sphere 3 internal cavity, the hollow sphere 3 is also provided with a rotating shaft 5, the rotating shaft 5 passes through the center of the hollow sphere 3 and the two ends are connected with the fuel tank respectively The inner wall of the body 1 is fixed; a support plate 6 is provided on the side of the fuel tank body 1, and a plurality of through holes are opened in the support plate 6, and the through holes communicate with the internal cavity of the fuel tank body 1. An internal thread is also provided inside; one end of the fuel pipe 2 is a metal joint 7, and an external thread is arranged on the metal joint 7, and ...

Embodiment 2

[0022] Such as figure 1 As shown, the present invention is a low-noise fuel storage and delivery assembly. On the basis of Embodiment 1, the lines connecting the center points of the two diversion openings 4 and the center of the hollow sphere 3 are perpendicular to each other.

Embodiment 3

[0024] Such as figure 1 As shown, the present invention is a low-noise fuel storage and delivery assembly. On the basis of Embodiment 1, the thickness of the support plate 6 in the direction where the fuel pipe 2 points to the fuel tank 1 is 10 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com