Inlet water control method of washing machine and washing machine

A water inflow control and washing machine technology, applied in the field of washing machines, can solve the problems of water flow to the floor and poor user experience, and achieve the effects of preventing dripping of window mats, reducing maintenance frequency, and reducing research and development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

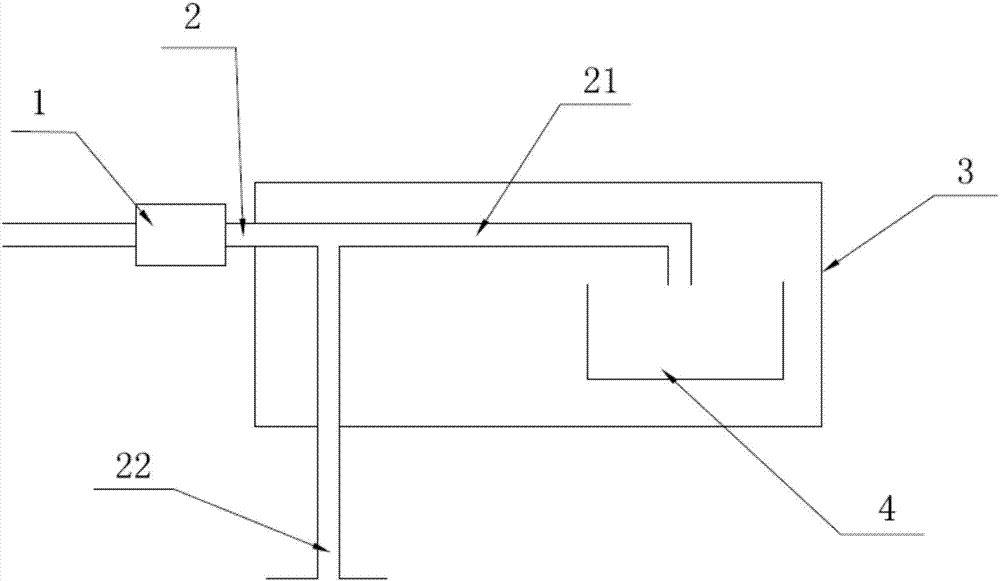

[0050] A washing machine, comprising a feeding device 3, a single water inlet valve 1, a plurality of pipelines branched from the water outlet of the same single water inlet valve 1 to the inside of the feeding device 3, including a first feeding device for detergent and / or additives A pipeline 21, a second pipeline 22 for spraying the observation window glass door and / or glass sealing window gasket.

[0051] In the prior art, the washing machine with the functions of spraying and washing additives needs to control the water intake through at least two solenoid valves, increasing the internal components of the washing machine, and the procedure is complicated and easily disordered when multiple solenoid valves are used to control the water intake, and the production and manufacturing high cost.

[0052] In addition, the increase of the solenoid valve will also increase the probability of failure of the washing machine, which is not conducive to the stability of the overall per...

Embodiment 2

[0085] The difference between this embodiment and the first embodiment is that the single water inlet valve 1 is arranged inside the dispensing device 3 , and no drawings are shown in this application.

[0086] A washing machine, comprising a feeding device 3, a single water inlet valve 1, a plurality of pipelines branched from the water outlet of the same single water inlet valve 1 to the inside of the feeding device 3, including a first feeding device for detergent and / or additives A pipeline 21, a second pipeline 22 for spraying the observation window glass door and / or glass sealing window gasket.

[0087]In the prior art, the washing machine with the functions of spraying and washing additives needs to control the water intake through at least two solenoid valves, increasing the internal components of the washing machine, and the procedure is complicated and easily disordered when multiple solenoid valves are used to control the water intake, and the production and manufact...

Embodiment 3

[0114] The difference between this embodiment and Embodiment 1 is:

[0115] The water inflow control method of the washing machine is different. In this embodiment, the washing machine is controlled to continue to inflow water for a time period of M, and then continue to inflow water after an interruption of a time period of N. Taking the time period of M+N as a cycle, water inflows for S periods, and S is Natural number and S>1.

[0116] The single water inlet valve 1 of the washing machine in this embodiment is arranged outside the dispensing device 3 and is connected with the dispensing device 3 through a pipeline.

[0117] The injection device 3 of the washing machine is provided with an additive chamber 4, and the interior 3 of the injection device is embedded with a water inlet pipeline 2;

[0118] One end of the water inlet pipeline 2 communicates with the water outlet of the single water inlet valve 1 , and the other end divides into first and second pipelines 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com