Multi-segment indoor ore drawing equipment capable of automatically adjusting height and bottom structure and method thereof

A bottom structure and automatic adjustment technology, applied in the field of simulated mine drawing, can solve the problems of long test period, material waste and high test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

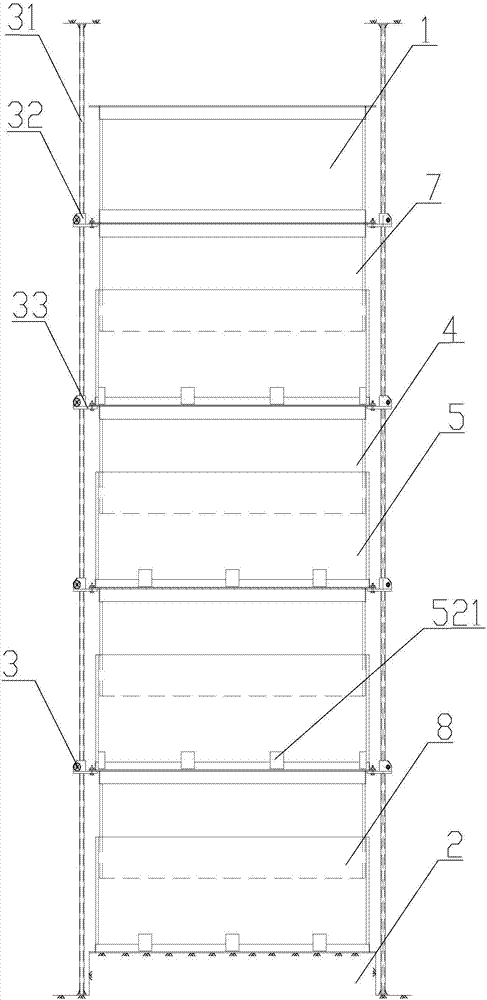

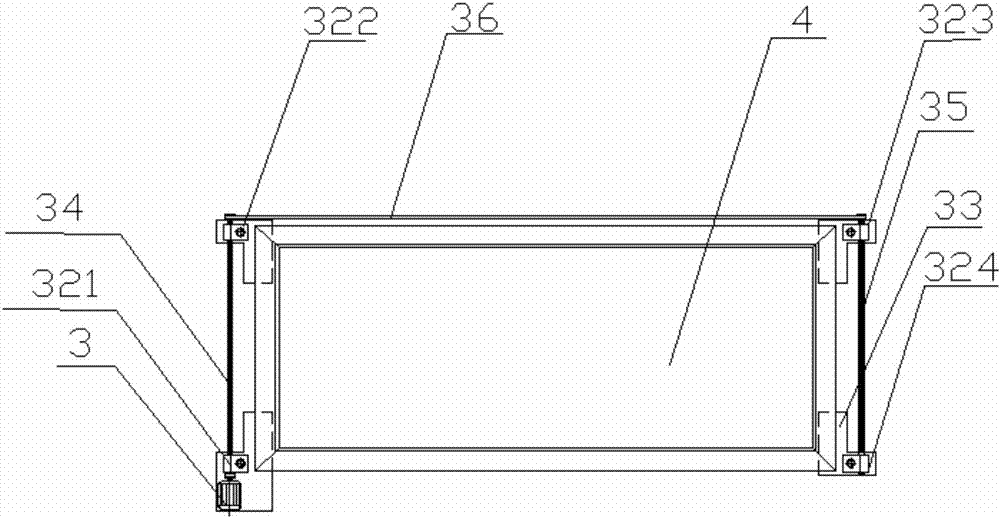

[0069] A multi-section indoor ore drawing device with automatic adjustment of height and bottom structure, consisting of Figure 1-7 As shown, including model waste rock box 1, several ore boxes, base 2 and elevator;

[0070] The model waste rock box 1 and several ore boxes are placed from top to bottom, and the bottom ore box is set on the base 2;

[0071] The waste rock box 1 is a box structure without an upper box plate and a lower box plate; the ore box is composed of an upper box body 4 and a lower box body 5, and the upper box body 4 has no upper box plate and a lower box plate , consisting of a front panel, a rear panel, a left side panel, and a right side panel, and the lower box body 5 has no upper box panel and a lower box panel, and is composed of a front panel, a rear panel, a left side panel, and a right side panel. The bottom of upper box body 4 is inserted lower box body 5 by the top of lower box body 5, and the size of all upper box body 4 is identical, and th...

Embodiment 2

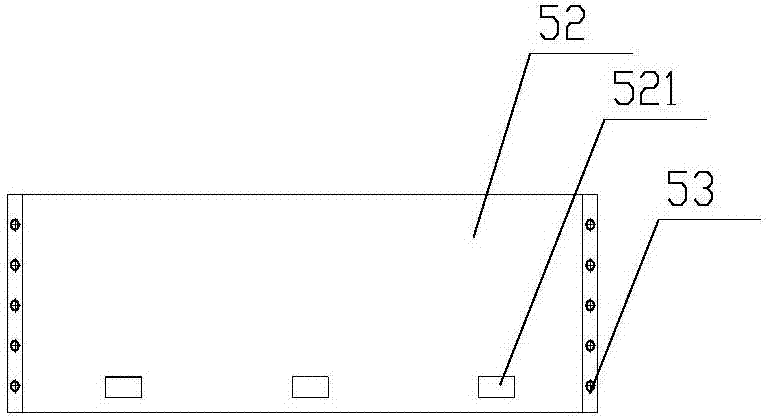

[0091] A multi-section indoor ore drawing device with automatic height adjustment and bottom structure, the structure is the same as that of Embodiment 1, further, the rear panel 51 and front panel 52 of the lower box body 5 of the ore box are fixedly connected to the lower box body 5 through a disassembly assembly 53 The box body 5, the disassembled components are bolts and screw holes, snap ring buckles or bolts and nuts corresponding to each other; the ore drawing bottom structure 6 is a disassembled bottom ore drawing assembly;

[0092] The front panel 52 is uniformly provided with several outlets of the ore-discharging approach along the transverse direction;

[0093] Several insertion holes 511 for inserting the peach-shaped columns corresponding to the outlets of the ore-out access road are evenly provided on the rear panel 51 in the transverse direction;

[0094] Further, the bottom ore drawing assembly is specifically composed of plate A62, plate B63 and plate C64;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com