LED constant-current drive circuit

A technology of constant current drive and circuit, which is applied in the field of LED constant current drive circuit, can solve the problems of high cost and complex circuit structure, and achieve the effect of low cost, less circuit electronic components, and low total harmonic distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

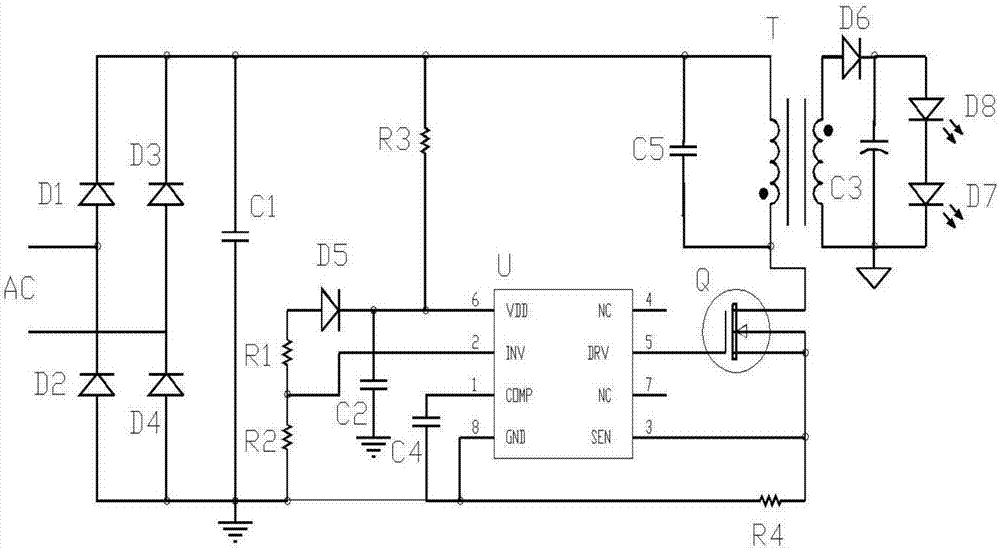

[0018] Such as figure 1 As shown, an LED constant current drive circuit, diodes D1~D4 and capacitor C1 are connected in parallel to form a rectifier filter module, resistors R1~R3 are connected in series with diode D5 and then parallel capacitor C2 is used to form a feedback sampling circuit, resistor R4, diode D6, capacitor C3 and C5, reverse transformer T and MOS tube Q form a flyback converter, U is a constant current drive control chip integrated with a PFC circuit, 1-pin COMP loop compensation, 2-pin INV feedback signal sampling, 3-pin SEN current sampling, 4 Pin and pin 7 NC are suspended, pin 5 is DRV external power MOS transistor gate drive pin, pin 6 is VDD chip power supply pin, pin 8 is grounded.

[0019] The AC mains input passes through the bridge rectifier circuit composed of diodes D1~D4 to output a half sine wave DC voltage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com