Piezosurgery machine work tip used for alveolar bone cutting

A working tip and alveolar bone technology, applied in the direction of dental saws, etc., can solve the problems of long wound healing time, large wound, low cutting efficiency of the working tip, etc., and achieve the effect of shortening the healing time, making the wound smaller, and improving the cutting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

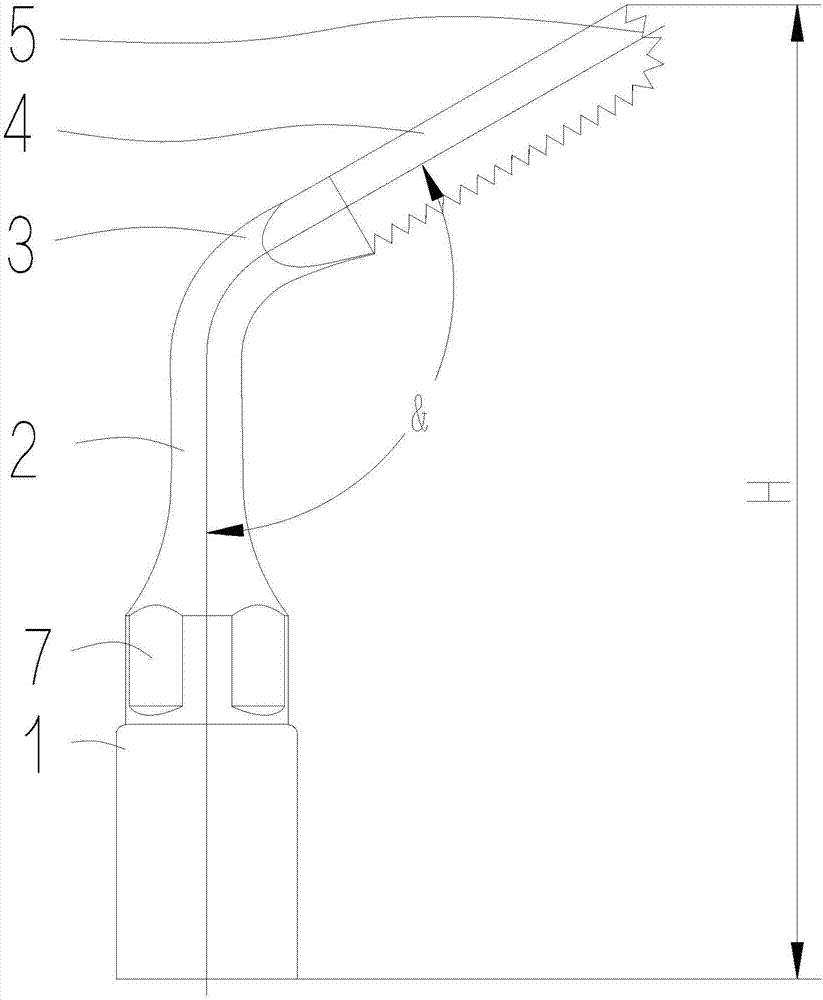

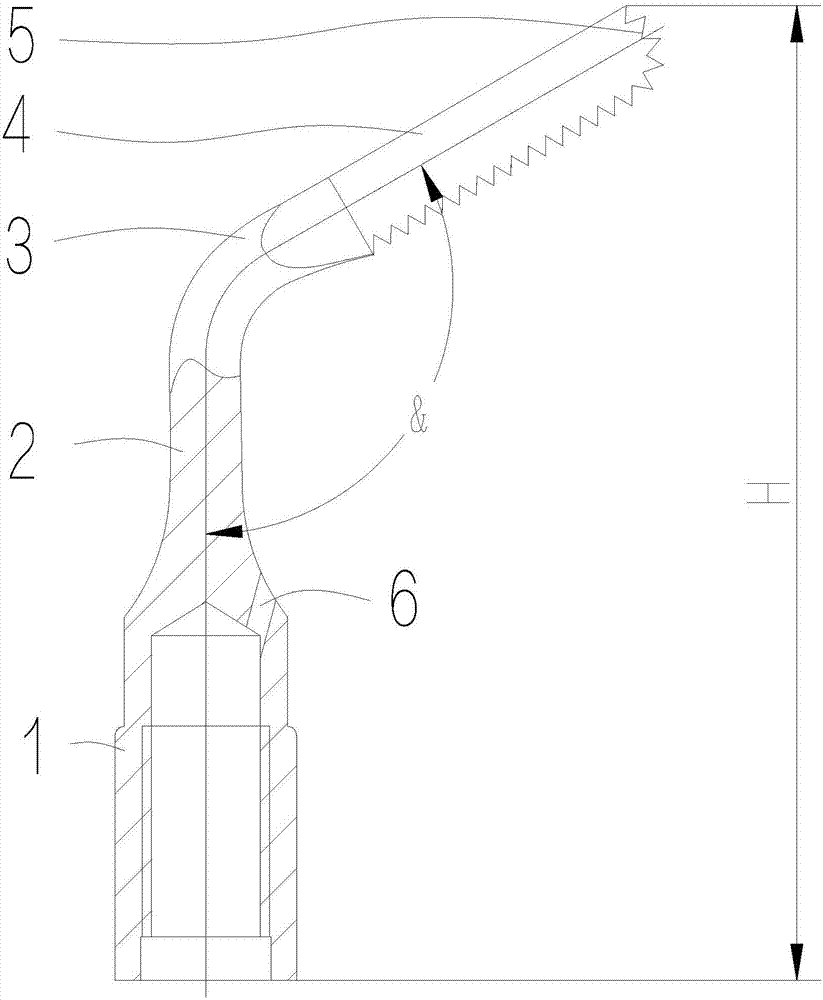

[0031] Such as figure 1 , 2 As shown in and 3, a working tip of an ultrasonic bone knife machine for alveolar bone cutting includes a working tip connecting part 1 which is threadedly connected with the ultrasonic bone knife machine and a working tip connecting part 1 which is fixedly connected sequentially in the same plane. The pointed neck 2, the working pointed part 3 and the working pointed working part 4 are integrally connected, the working pointed part 3 is arc-shaped, and one end thereof is connected with the end of the working pointed neck 2, and the working pointed working part 4 Smooth transition connection with the working tip 3, one end of the working tip 4 is connected to the other end of the working tip 3, the other end and the lower side of the working tip 4 are provided with a serrated blade part 5, the working tip works Part 4 is flat and long. The thread is arranged inside the working tip connection part 1 .

[0032] The corner where the other end of the...

Embodiment 2

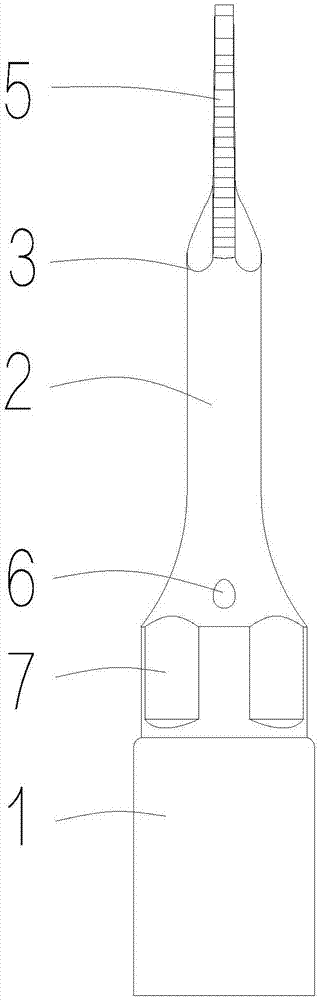

[0040] Such as Figure 4 , 5 As shown in and 6, the other end and the upper side of the working tip working part 4 are provided with a serrated blade part 5, the working tip working part 4 is flat and strip-shaped, and the other end of the working tip working part 4 is connected to the upper side The corners are substantially circular arc zigzag transitions, and the rest of the structure is the same as that of the first embodiment.

[0041] The blade parts 5 are arranged on different sides, which are convenient for splitting the alveolar bone in different orientations, effectively protect the periosteum at the edge of the alveolar bone, shorten the healing time, and have high cutting efficiency.

[0042] The beneficial effects of the present invention are: the structure of the working tip of the ultrasonic bone knife machine can well transmit the ultrasonic mechanical vibration effect to the working part of the working tip, and can cut to the deep part of the alveolar bone fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Vertical height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com