Numerical control grooving machine achieving automatic feeding and steering

A CNC slotting machine and automatic feeding technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as high production costs, low work efficiency, and uncertainty in product molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

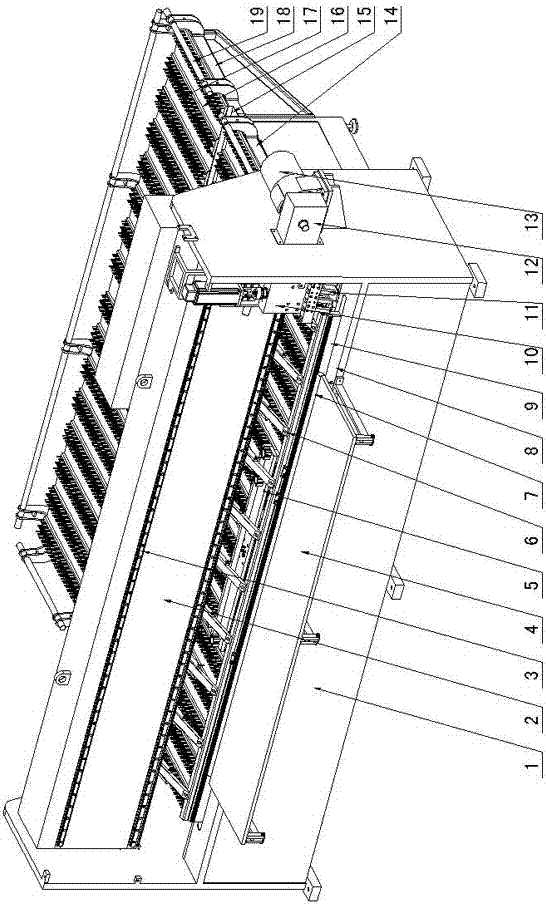

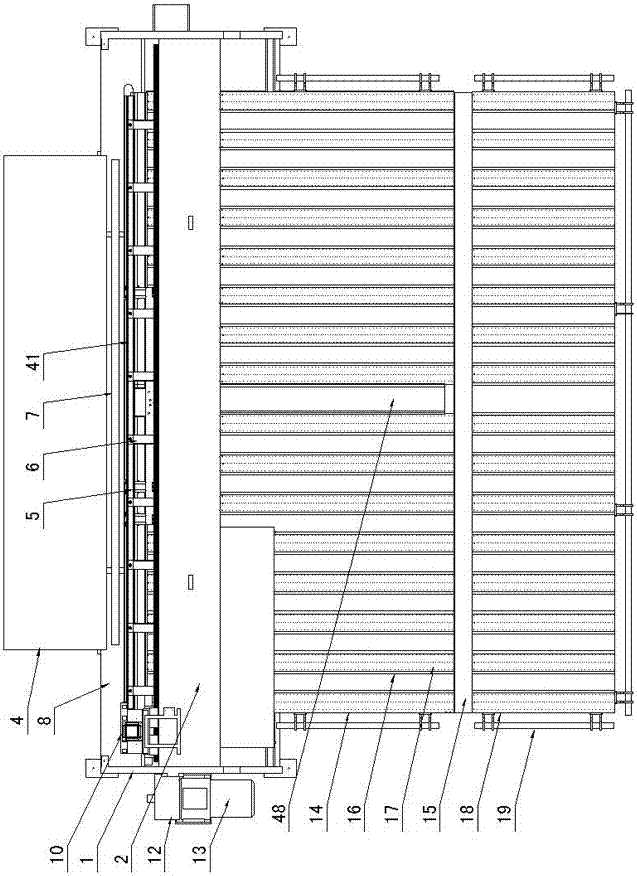

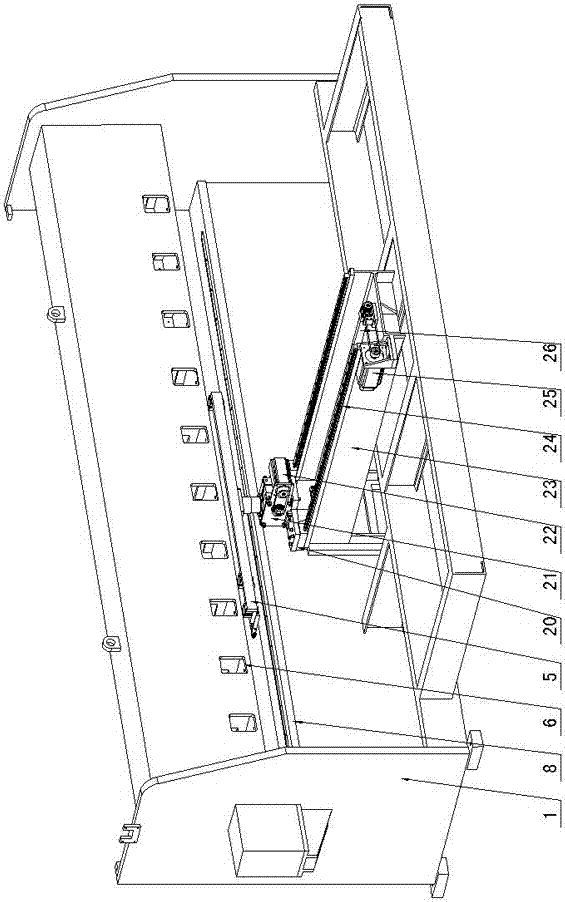

[0025] Figure 1 to Figure 6 Shown, for the present invention creates the specific embodiment of the numerically controlled slotting machine of automatic feeding steering, it comprises frame 1, upper beam 2 and workbench 8 fixed on the frame 1, pressure groove plate 41, slotting mechanism 10. Transmission mechanism 12 and working motor 13. The transmission mechanism 12 includes left and right transmission wheels arranged on both sides of the frame 1, and a transmission belt 29 connected to the left and right transmission wheels. The working motor 13 drives the transmission belt through the reducer and the transmission wheel 29 rotations, the transmission wheel at the other end is provided with the tensioning mechanism that adjusts the tightness of transmission belt 29, and working motor 13 drives slotting mechanism 10 to move left and right on upper beam 2 through transmission mechanism 12, and the front and back of described workbench 8 are correspondingly provided with There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com