Fabric cutting equipment

A device and fabric technology, applied in the field of fabric cutting equipment, can solve problems such as cutting fabric errors and affecting cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

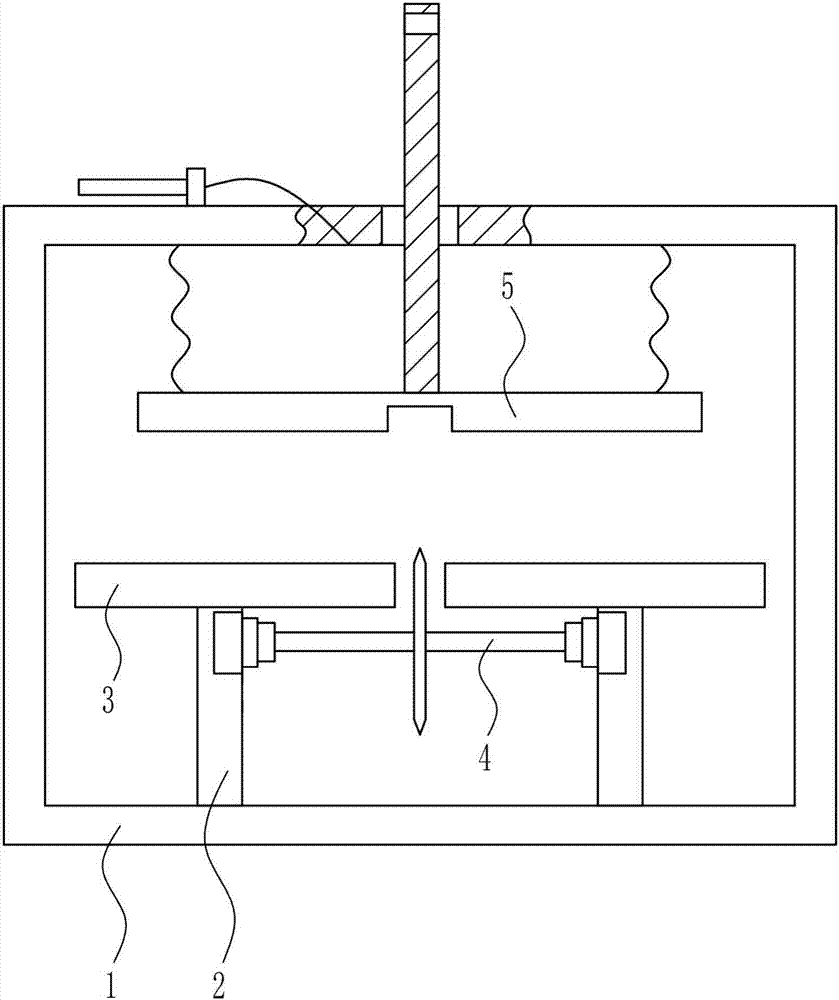

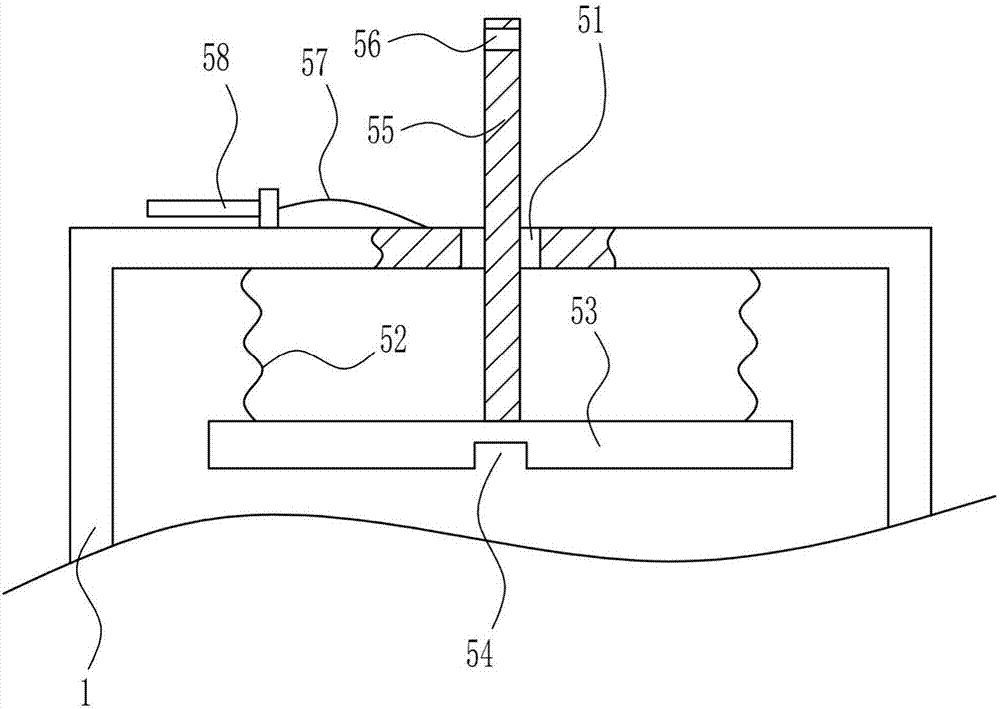

[0030] A cloth cutting device such as Figure 1-6 As shown, it includes a mounting frame 1, a support plate 2, a placement plate 3, a cutting device 4 and a fixing device 5. The bottom of the mounting frame 1 is symmetrically provided with a support plate 2, and the top of the support plate 2 is provided with a placement plate 3. A cutting device 4 is provided between the inner upper parts of the boards 2, and a fixing device 5 is provided on the inner top of the mounting frame 1.

Embodiment 2

[0032] A cloth cutting device such as Figure 1-6 As shown, it includes a mounting frame 1, a support plate 2, a placement plate 3, a cutting device 4 and a fixing device 5. The bottom of the mounting frame 1 is symmetrically provided with a support plate 2, and the top of the support plate 2 is provided with a placement plate 3. A cutting device 4 is provided between the inner upper parts of the boards 2, and a fixing device 5 is provided on the inner top of the mounting frame 1.

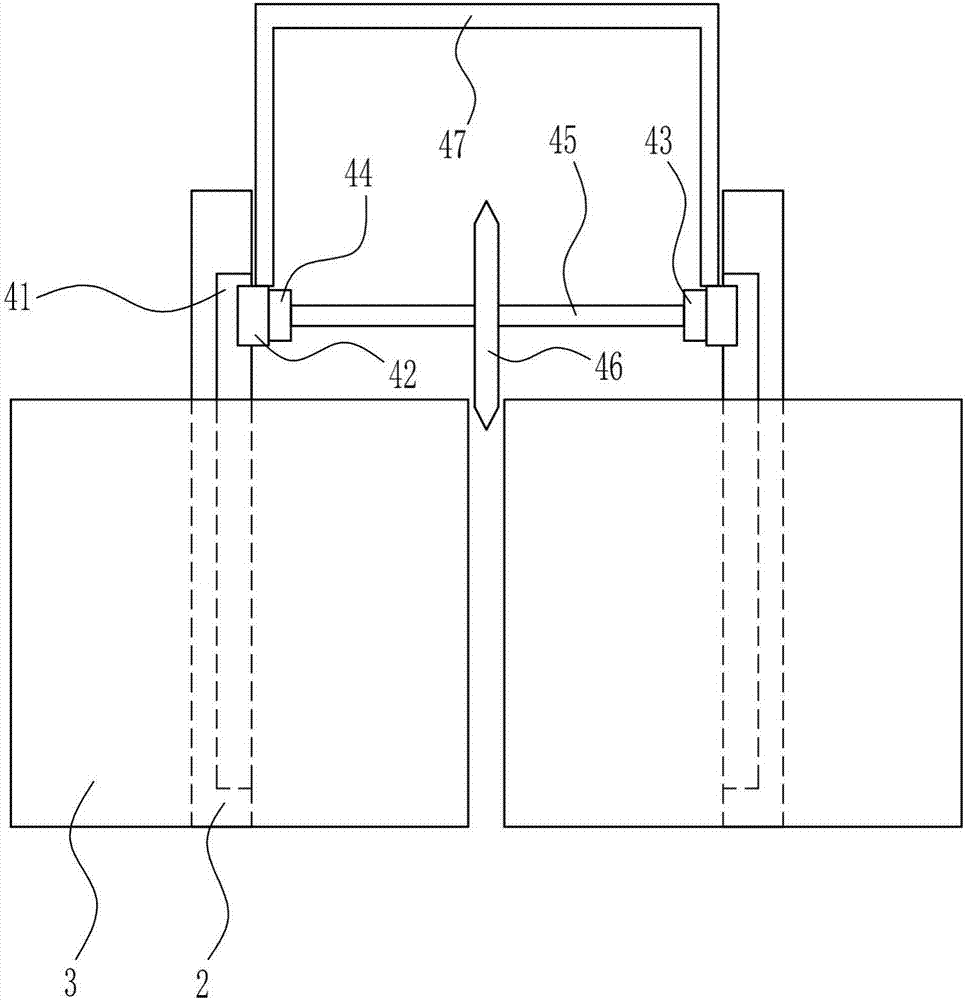

[0033] The cutting device 4 includes a first slide rail 41, a first slide block 42, a bearing seat 43, a motor 44, a rotating shaft 45, a cutting gear 46 and a concave push rod 47, and the upper part of the support plate 2 is embedded with the first slide rail 41. The inner side of the first slide rail 41 is slidably connected with the first slider 42, the inner side of the first slider 42 on the right side is provided with a bearing seat 43, the inner side of the first slider 42 on the left side i...

Embodiment 3

[0035] A cloth cutting device such as Figure 1-6As shown, it includes a mounting frame 1, a support plate 2, a placement plate 3, a cutting device 4 and a fixing device 5. The bottom of the mounting frame 1 is symmetrically provided with a support plate 2, and the top of the support plate 2 is provided with a placement plate 3. A cutting device 4 is provided between the inner upper parts of the boards 2 , and a fixing device 5 is provided on the inner top of the mounting frame 1 .

[0036] The cutting device 4 includes a first slide rail 41, a first slide block 42, a bearing seat 43, a motor 44, a rotating shaft 45, a cutting gear 46 and a concave push rod 47, and the upper part of the support plate 2 is embedded with the first slide rail 41. The inner side of the first slide rail 41 is slidably connected with the first slider 42, the inner side of the first slider 42 on the right side is provided with a bearing seat 43, the inner side of the first slider 42 on the left side ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap