Bridge incremental launching construction technology

A technology for jacking construction and bridges, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as obstruction of river and road traffic, inconvenience for residents to travel, etc., to improve jacking accuracy, fast construction progress, and simple construction process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

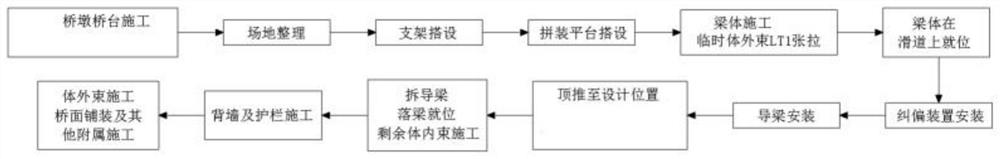

Method used

Image

Examples

Embodiment 1

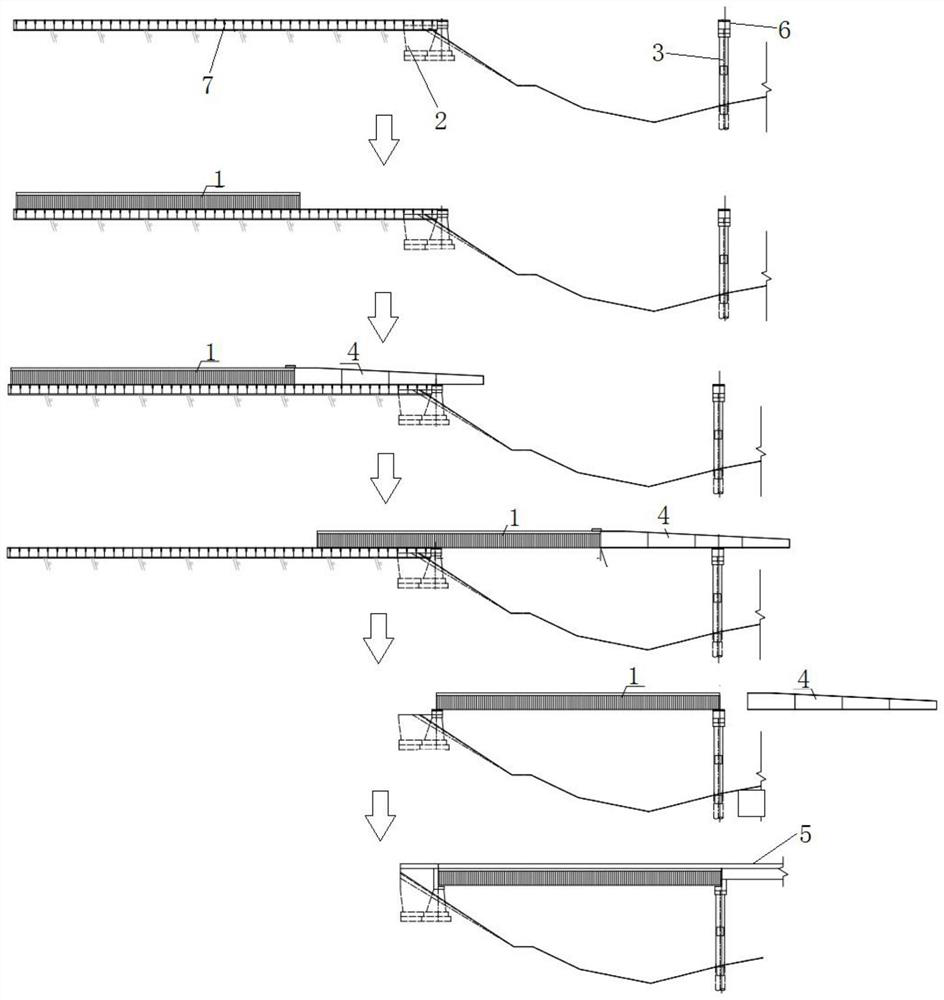

[0048] A bridge for the new bridge, the bridge is a river located in Alluvial terraces topography, elevation between 146.9-150.4m. Now the bridge across a river, a width of 40m during drilling construction, water depth of about 5m. The present embodiment is path and channel centerline intersection angle 98 °, the orthogonal bridge design. The main bridge 1 × 60m corrugated steel webs prestressed concrete box girder, bridge approach using 3 × 30m Fabricated Prestressed concrete T beam, with a total of two full bridge. Main bridge deck from the bottom layer of a flexible waterproof and 10cm thick asphalt concrete pavement, bridge deck slope bidirectional 2%; and on both sides of a first abutment provided at the pier D80 expansion joints, main bridge pot bearings, bridge approach using plate bearing pier pile using column, column diameter 1.8m, 2.0m diameter pile, pier foundation embedded using rock foundation, abutment gravity U-station, base expanded. Will now be changed to the mai...

Embodiment 2

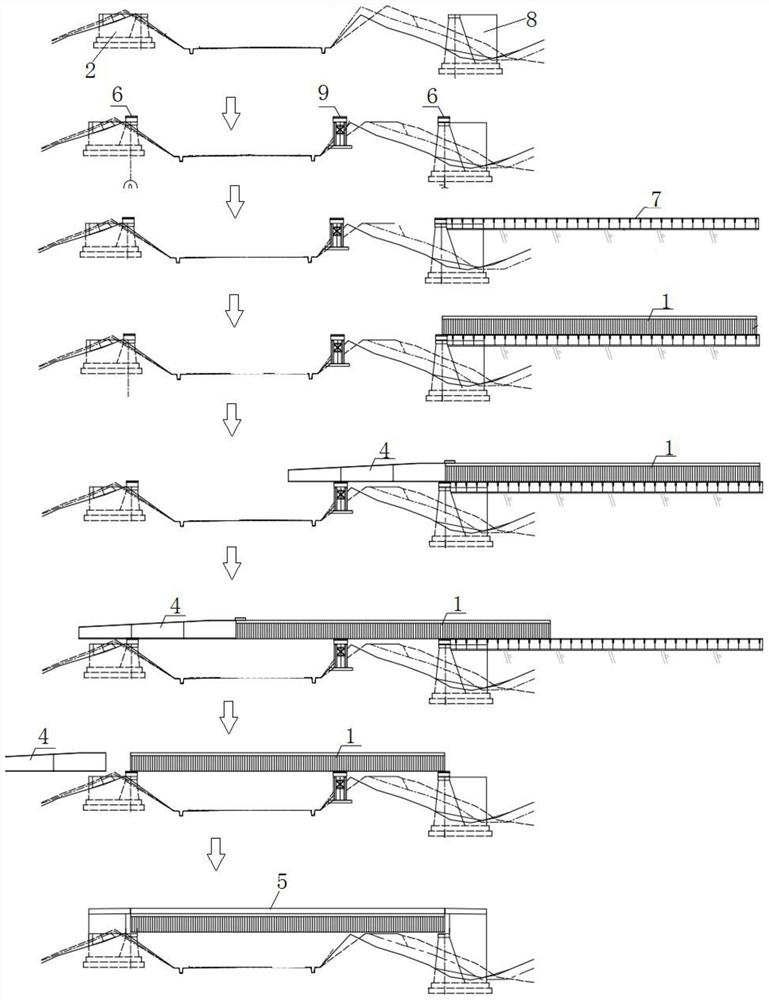

[0053] Status as a high-speed two-way 24.5m four-lane highway, there are eight-lane widening of the requirements according to the relevant departments of planning, after widening roadbed section is 43.25m, pass clearance of not less than 6m. The present embodiment the high speed line intersecting angle is 90 °, the orthogonal design bridge, simply supported span of 60 meters across the bridge structure, the bridge is oriented by the layer of a flexible waterproof and 10cm thick asphalt concrete pavement, bridge deck bidirectional 2 % slope, abutments are located on both sides of D80 expansion joints, the use of pot bearings, bridge abutment using gravity U station, broaden the base. Bridge superstructure original design double steel box - concrete composite beams (double channel steel box composite beam), steel specimens of single construction program - a combination of a span of the lifting mixed, so a greater impact on existing highway construction program, in order to ensure th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap