An environmentally friendly thermoplastic circular tube composite board

A composite board and round tube technology, applied in the field of composite boards, can solve the problems of low strength of paper honeycomb, small application range, high price and weight of aluminum honeycomb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For better understanding and implementation, the present invention will be described in detail below in conjunction with the accompanying drawings.

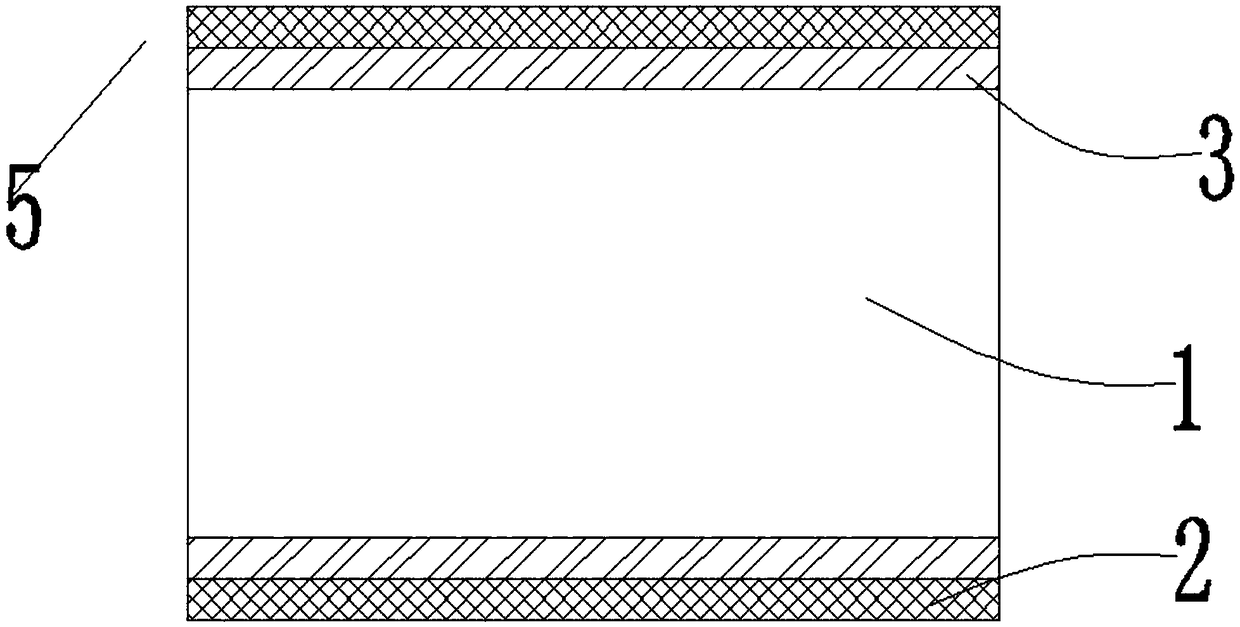

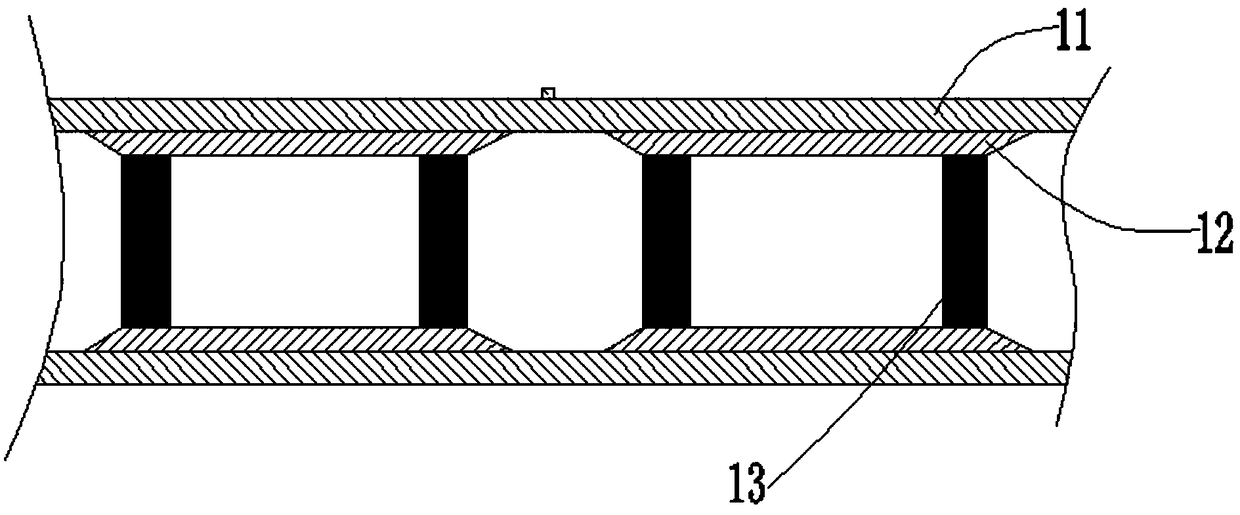

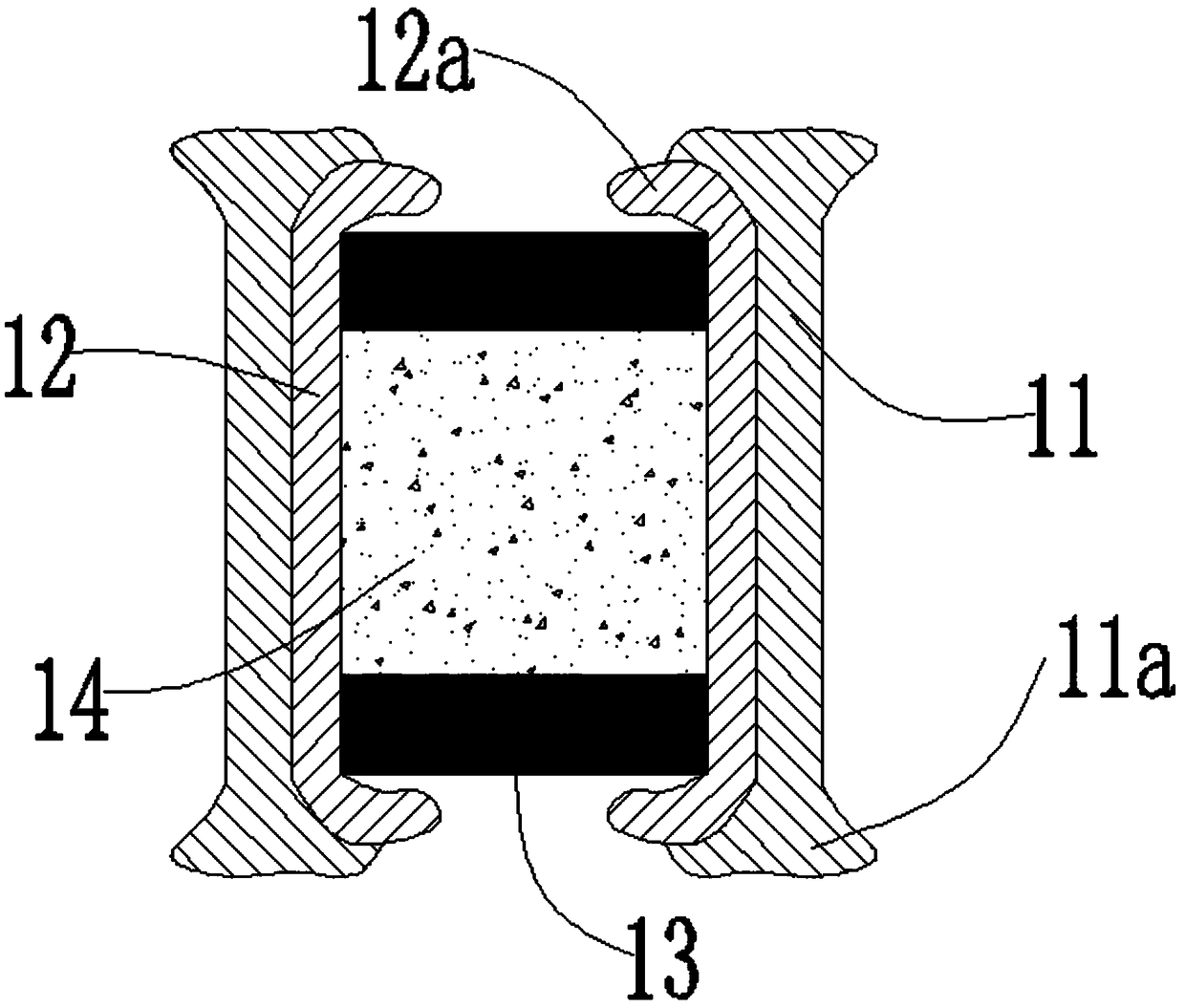

[0021] Such as figure 1 , figure 2 , image 3 As shown, an environment-friendly thermoplastic circular tube composite panel comprises a composite circular tube layer 1 and a panel layer 5, and the panel layer 5 is fixed on both ends of the composite circular tube layer 1 by heat bonding, and the composite circular tube layer Layer 1 is composed of an inner tube layer 12 and an outer tube layer 11, the inner tube layer 12 is a high melting point material layer, the outer tube layer 11 is a low melting point material layer, and the outer tube layer 11 is two After the end is heated by thermal bonding, a large gelatinous end 11a is formed, and the large gelatinous end 11a is bonded to the panel layer 5; the inner circular tube layer 12 is a high melting point material layer, and the inner circular tube The layer 12 is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com