Propeller forward and reverse rotation device of side thruster

A propeller, forward and reverse technology, applied in the direction of propulsion transmission, transmission with synchronous propulsion components, ship propulsion, etc., can solve the problems of large space required, large equipment layout size, unreasonable force on gear pairs, etc. The effect of avoiding reversal, improving service life and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the embodiment shown in accompanying drawing:

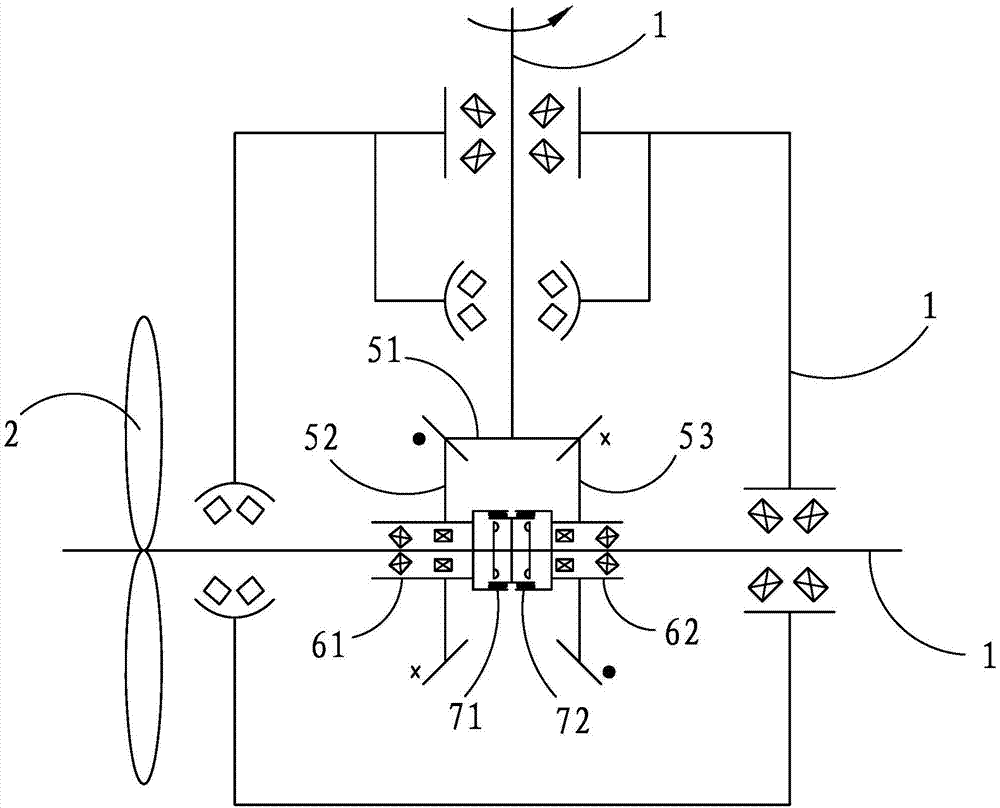

[0013] See attached figure 1 As shown, a side propeller propeller 2 forward and reverse device, which includes a gearbox 1, a transmission assembly arranged in the gearbox 1, and a propeller 2 arranged on the gearbox 1, and the transmission assembly includes a vertically arranged input The shaft 3 and the output shaft 4 arranged horizontally, the input shaft 3 and the output shaft 4 are connected through bevel gear transmission, the propeller 2 is fixedly arranged on the output shaft 4, the lower end of the input shaft 3 is provided with a first bevel gear 51, and the output shaft 4 is provided with a first sleeve 61 and a second sleeve 62 for rotation, the first sleeve 61 is provided with a second bevel gear 52 which meshes with the first gear, and the second sleeve 62 is provided with a The third bevel gear 53 meshing with each other, the second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com