Testing system and method for phase consistency among frequency variable T/R assembly channels

A test system and consistency technology, applied in transmission systems, electrical components, transmission monitoring, etc., can solve problems such as limiting the accuracy of test results, poor versatility, and increasing system construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0108] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

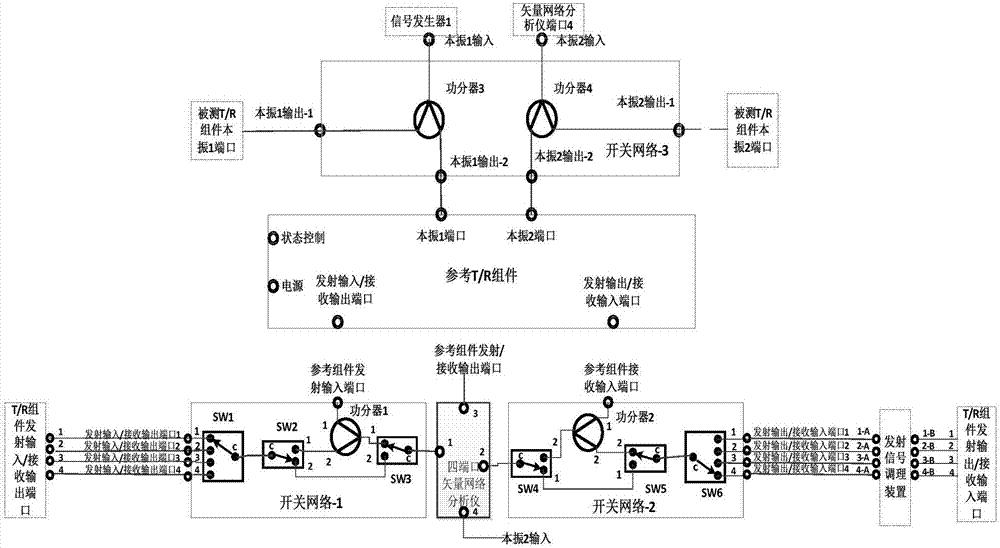

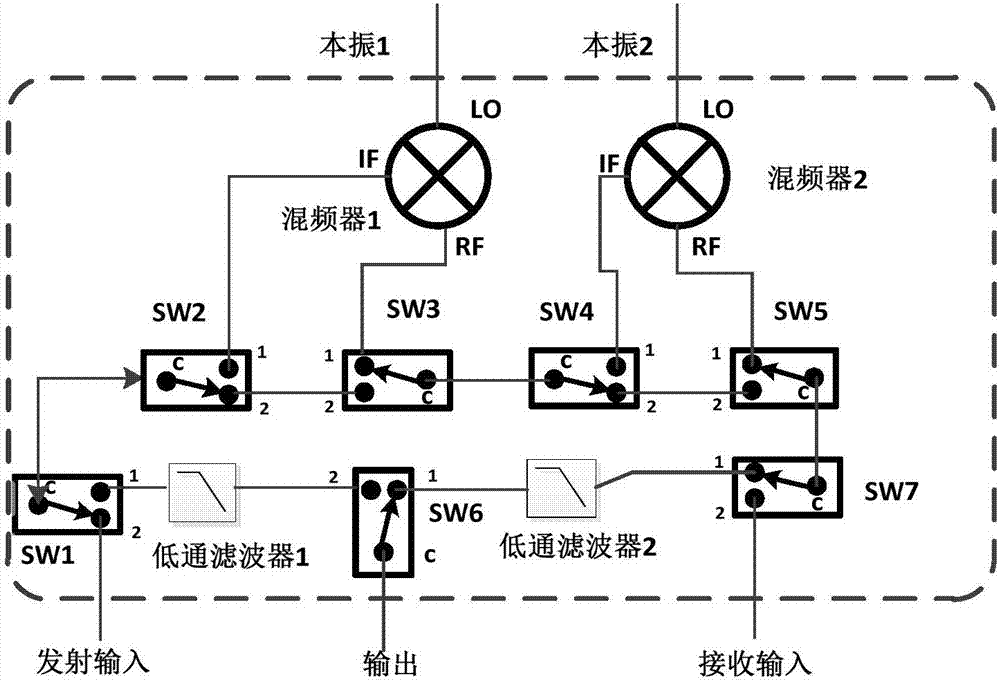

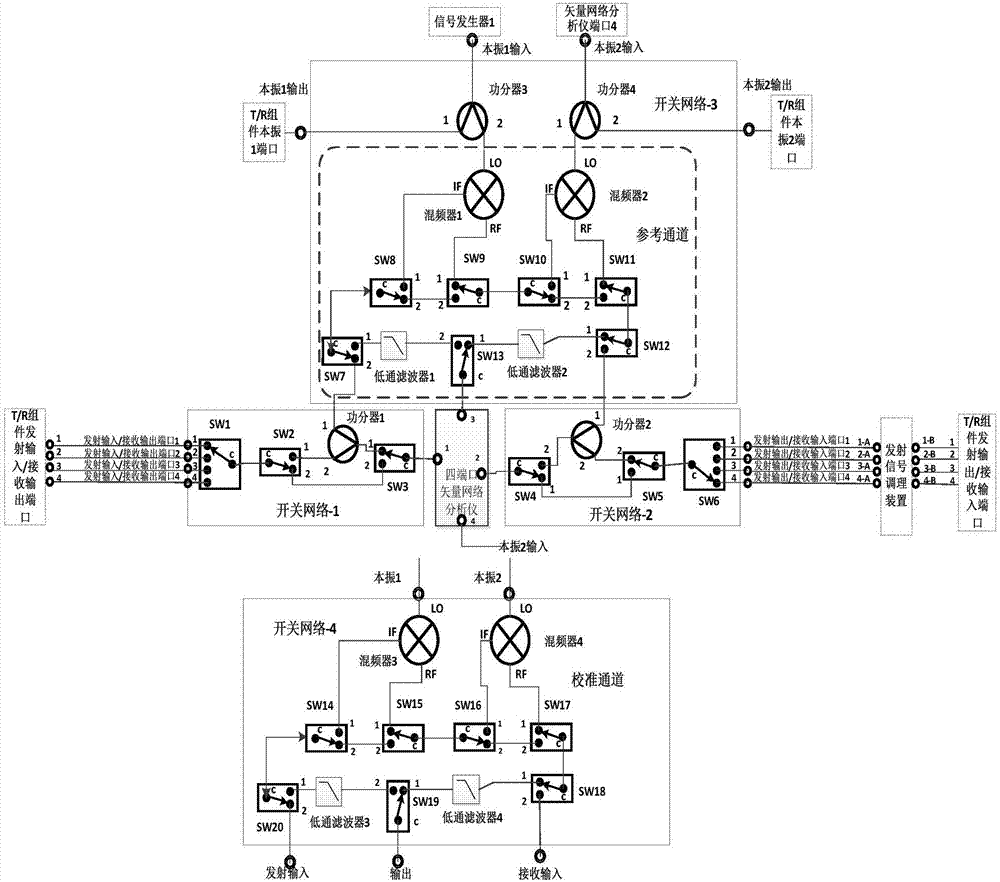

[0109] In view of the shortcomings and disadvantages of the current testing method and device, the present invention proposes a reference channel and a calibration channel based on a double-balanced mixer, and on this basis realizes the test of the phase consistency between the channels of the variable frequency T / R component. The present invention no longer uses the component under test as the reference component and the calibration component, but according to the frequency conversion T / R component is generally a two-stage frequency conversion working system, two-stage mixers are used in series as the reference channel and the calibration channel, and the reference channel and the calibration channel Channels are completely consistent. In practical applications, both the reference channel and the calibration channel can be built into the switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com