High-temperature optical fiber probe convenient for cooling protection

A fiber optic probe, high temperature technology, applied in the field of infrared detection, can solve problems such as errors, troublesome construction and maintenance, inability to secure certification, etc., to achieve the effects of accurate data, long running time, and error avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

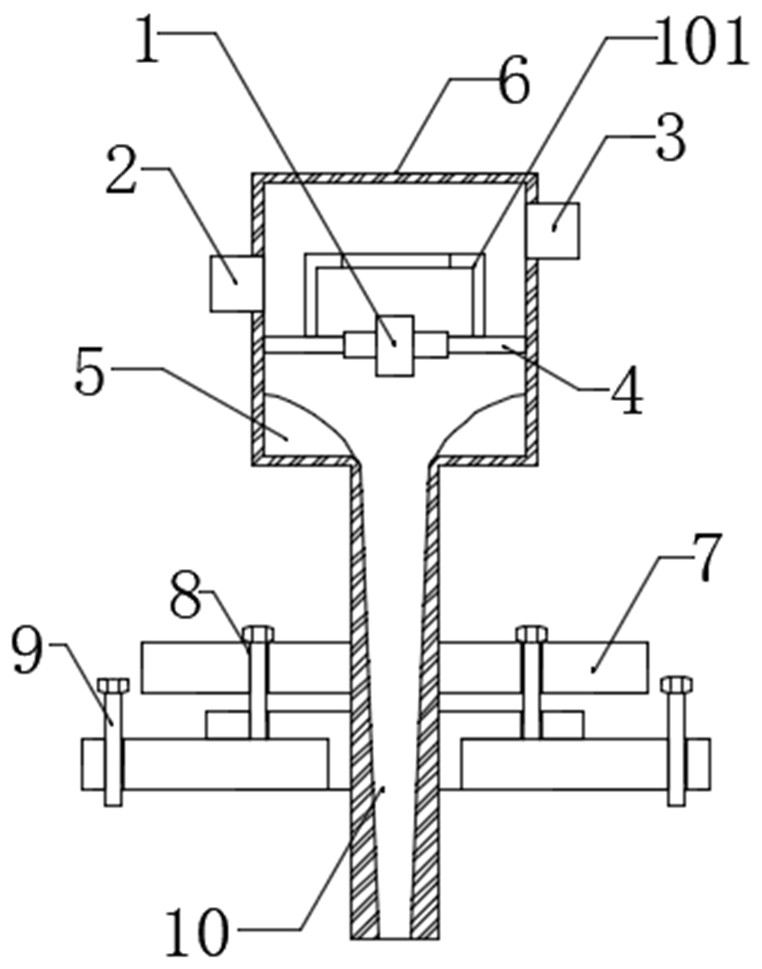

[0029] Such as figure 1 As shown, a kind of high-temperature optical fiber probe that is convenient for cooling protection includes an optical fiber collimator 1, a cooling protection casing 6 and an infrared radiation energy processing system, and the inside of the top of the cooling protection casing 6 is equipped with a first fixing flange 4, the first An optical fiber collimator 1 is installed inside the fixed flange 4, and the optical fiber collimator 1 is installed inside the cooling protective shell 6 through the first fixed flange 4;

[0030] A cooling air source inlet 2 is installed on one side of the cooling protective shell 6, and a high temperature optical fiber outlet 3 is installed on the other side of the cooling protective shell 6. The height of the cooling air source inlet 2 is not higher than the height of the high temperature optical fiber outlet 3.

[0031] In this embodiment, the pins of the detector 13 are connected to a circuit board, and the fiber colli...

Embodiment 2

[0036] Such as Figure 1-2 As shown, a kind of high-temperature optical fiber probe that is convenient for cooling protection includes an optical fiber collimator 1, a cooling protection casing 6 and an infrared radiation energy processing system, and the inside of the top of the cooling protection casing 6 is equipped with a first fixing flange 4, the first An optical fiber collimator 1 is installed inside the fixed flange 4, and the optical fiber collimator 1 is installed inside the cooling protective shell 6 through the first fixed flange 4;

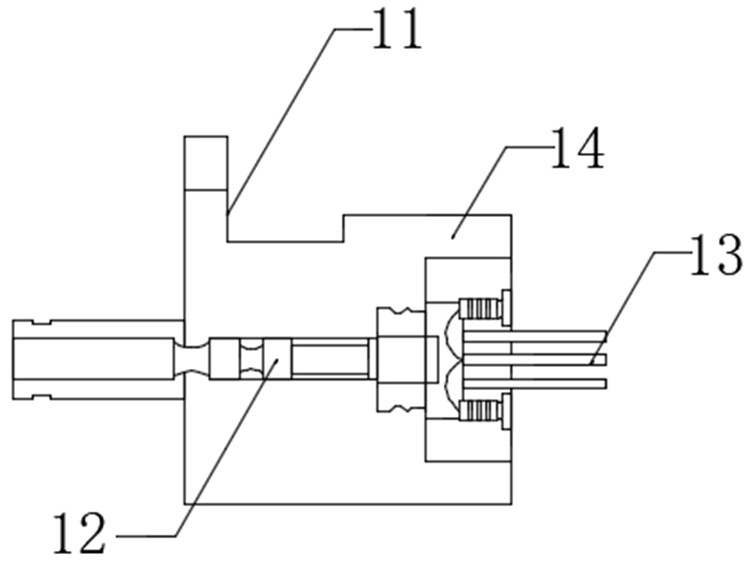

[0037] The infrared radiation energy processing system includes a detector 13, a focusing imaging mirror group 12 and a TE cooling plate. The detector 13 is fixedly installed on a detection base 14, and the bottom of the detection base 14 is equipped with a focusing imaging base 11, and a focusing imaging mirror group 12 One side is installed with a TE cooling plate.

[0038] In this embodiment, a cooling air source inlet 2 is instal...

Embodiment 3

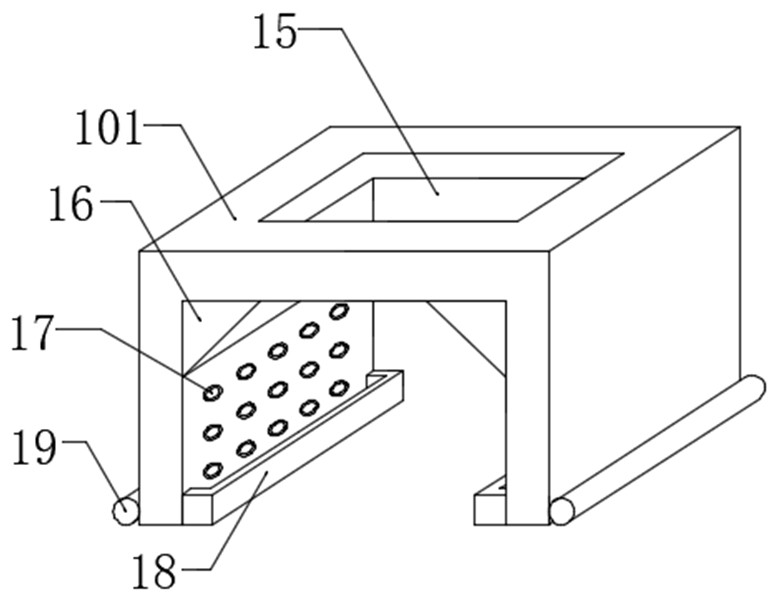

[0046] Such as figure 1 , image 3 with Figure 4 As shown, a kind of high-temperature optical fiber probe that is convenient for cooling protection includes an optical fiber collimator 1, a cooling protection casing 6 and an infrared radiation energy processing system, and the inside of the top of the cooling protection casing 6 is equipped with a first fixing flange 4, the first An optical fiber collimator 1 is installed inside the fixed flange 4, and the optical fiber collimator 1 is installed inside the cooling protective shell 6 through the first fixed flange 4;

[0047] In this embodiment, the infrared radiation energy processing system includes a detector 13, a focusing imaging lens group 12, and a TE cooling plate. The detector 13 is fixedly installed on a detection base 14, and a focusing imaging base 11 is installed on the bottom of the detection base 14. , one side of the focusing imaging lens group 12 is installed with a TE cooling plate.

[0048] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com