Optical fiber temperature sensor used for oil-immersed transformer winding

An oil-immersed transformer, optical fiber temperature technology, applied to thermometers, thermometers, instruments and other directions with physical/chemical changes, can solve the problems of limited test range, unreliability, installation space requirements, etc., to achieve simple and reliable packaging, insertion The effect of low losses and no temperature drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

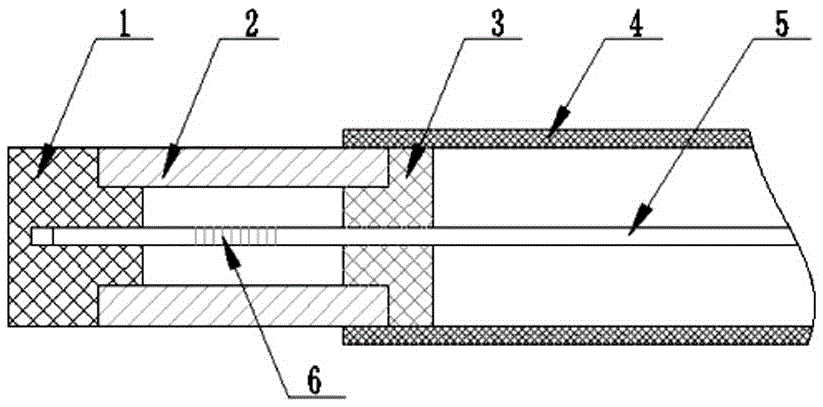

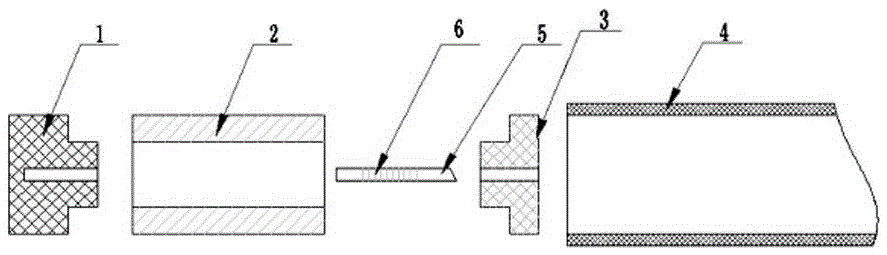

[0034] Figure 1 is a schematic diagram of the overall structure of an optical fiber temperature sensor for an oil-immersed transformer winding in the present invention; Figure 2 is a schematic diagram of the split structure of an optical fiber temperature sensor for an oil-immersed transformer winding in the present invention;

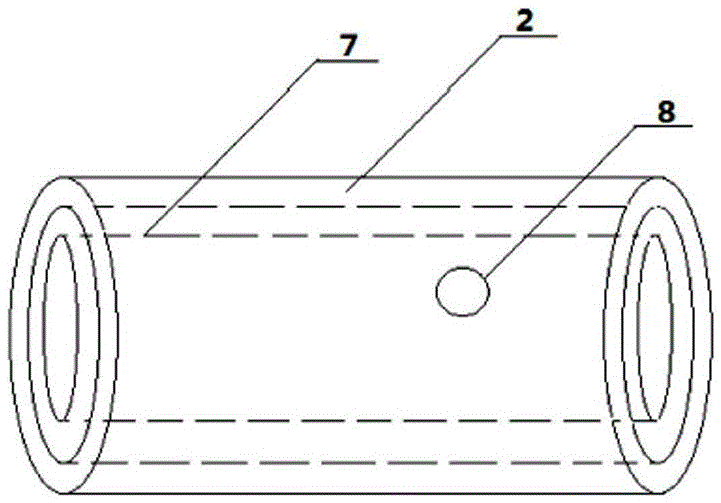

[0035] As shown in Figure 1 and Figure 2: an optical fiber temperature sensor for an oil-immersed transformer winding, it is characterized in that: the optical fiber temperature sensor is composed of two protective tubes 2 and 4, two fixed caps 1 and 3 and transmission optical fiber 5 The transmission fiber 5 is provided with a fiber grating 6; the two protection tubes 2 and 4 are respectively connected to the two fixing caps 1 and 3, and the two protection tubes 2 and 4 are hollow; the One of the fixed caps 3 is provided with a central through hole 11, and the other fixed cap 1 is provided with a groove 12, and the transmission optical fiber 5 passes t...

Embodiment 2

[0052] Fig. 1 is a schematic diagram of the overall structure of an optical fiber temperature sensor for an oil-immersed transformer winding in the present invention; Fig. 2 is

[0053] A schematic diagram of a split structure of an optical fiber temperature sensor for an oil-immersed transformer winding in the present invention;

[0054] As shown in Figure 1 and Figure 2: an optical fiber temperature sensor for oil-immersed transformer windings, characterized in that: the optical

[0055] The fiber temperature sensor is composed of two protective tubes 2 and 4, two fixed caps 1 and 3 and a transmission fiber 5; the transmission fiber 5 is provided with a fiber grating 6; the two protection tubes 2 and 4 are respectively connected with two Two fixed caps 1 and 3 are connected, and the two protective tubes 2 and 4 are hollow; one of the fixed caps 3 is provided with a central through hole 11, and the other fixed cap 1 is provided with a groove 12 for transmission The optical f...

Embodiment 3

[0068] Figure 1 is a schematic diagram of the overall structure of an optical fiber temperature sensor for an oil-immersed transformer winding according to the present invention.

[0069] Fig. 2 is a schematic diagram of a split structure of an optical fiber temperature sensor for an oil-immersed transformer winding according to the present invention.

[0070] As shown in Figure 1 and Figure 2: an optical fiber temperature sensor for an oil-immersed transformer winding, it is characterized in that: the optical fiber temperature sensor is composed of two protective tubes 2 and 4, two fixed caps 1 and 3 and transmission optical fiber 5 Composition; the transmission fiber 5 is provided with a fiber grating 6; the two protection tubes 2 and 4 are respectively connected to the two fixing caps 1 and 3, and the two protection tubes 2 and 4 are hollow; the One of the fixed caps 3 is provided with a central through hole 11, and the other fixed cap 1 is provided with a groove 12, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com