CNC machine tool magazine

A technology for CNC machine tools and tool magazines, applied in the field of tool magazines, can solve the problems of slow response speed, complex structure, low rotation indexing accuracy, etc., and achieve the effects of fast response speed, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below by means of drawings and embodiments.

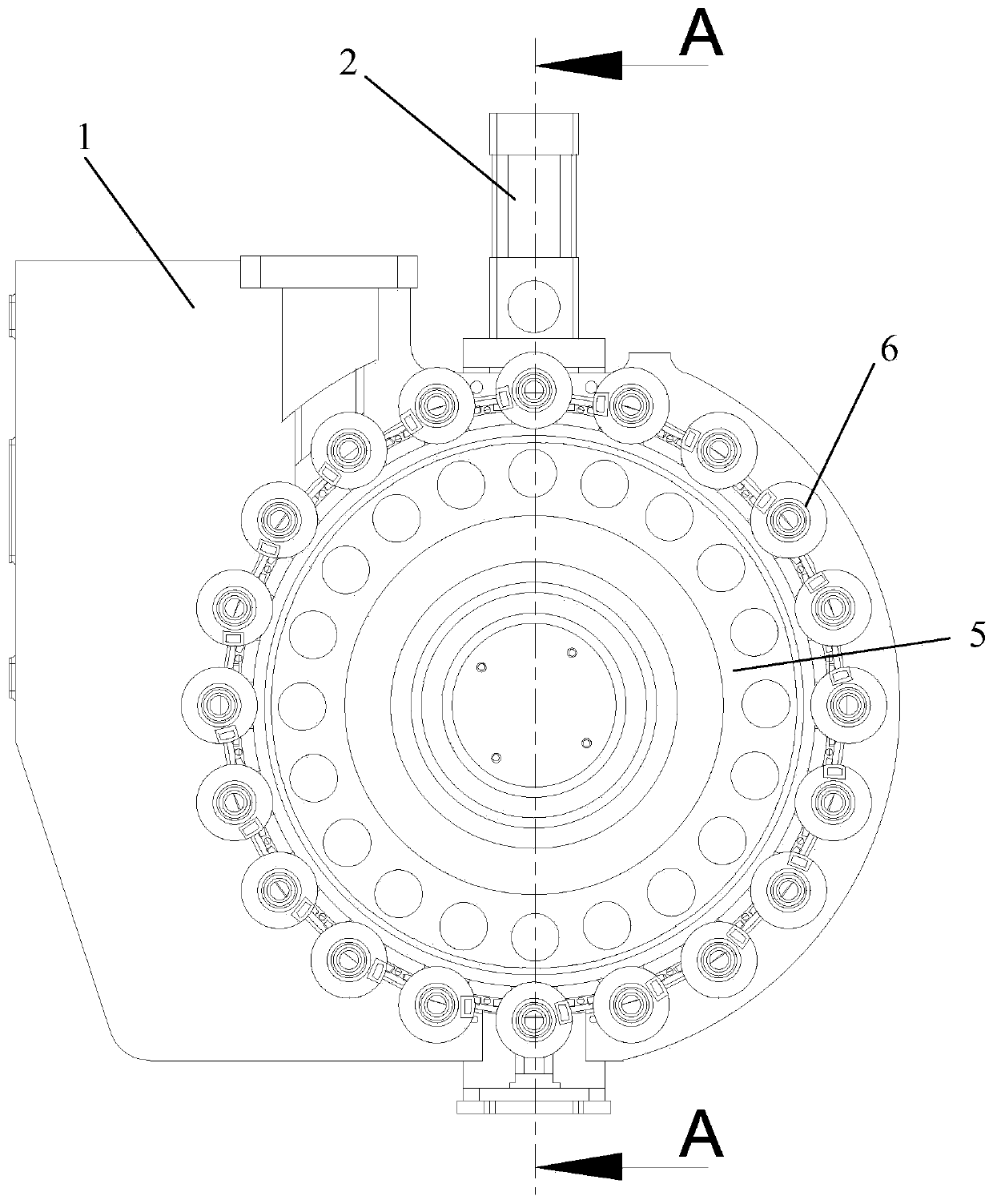

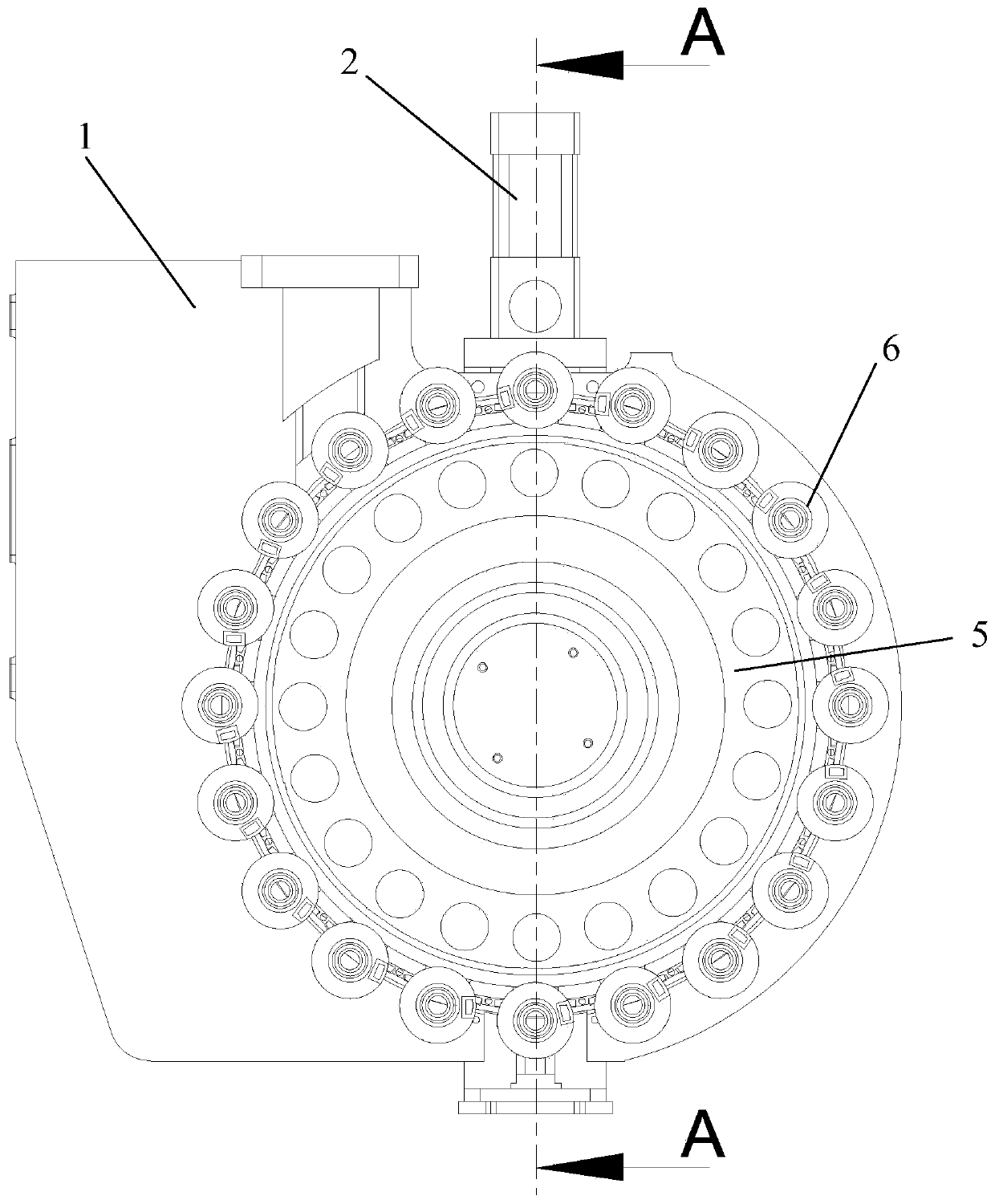

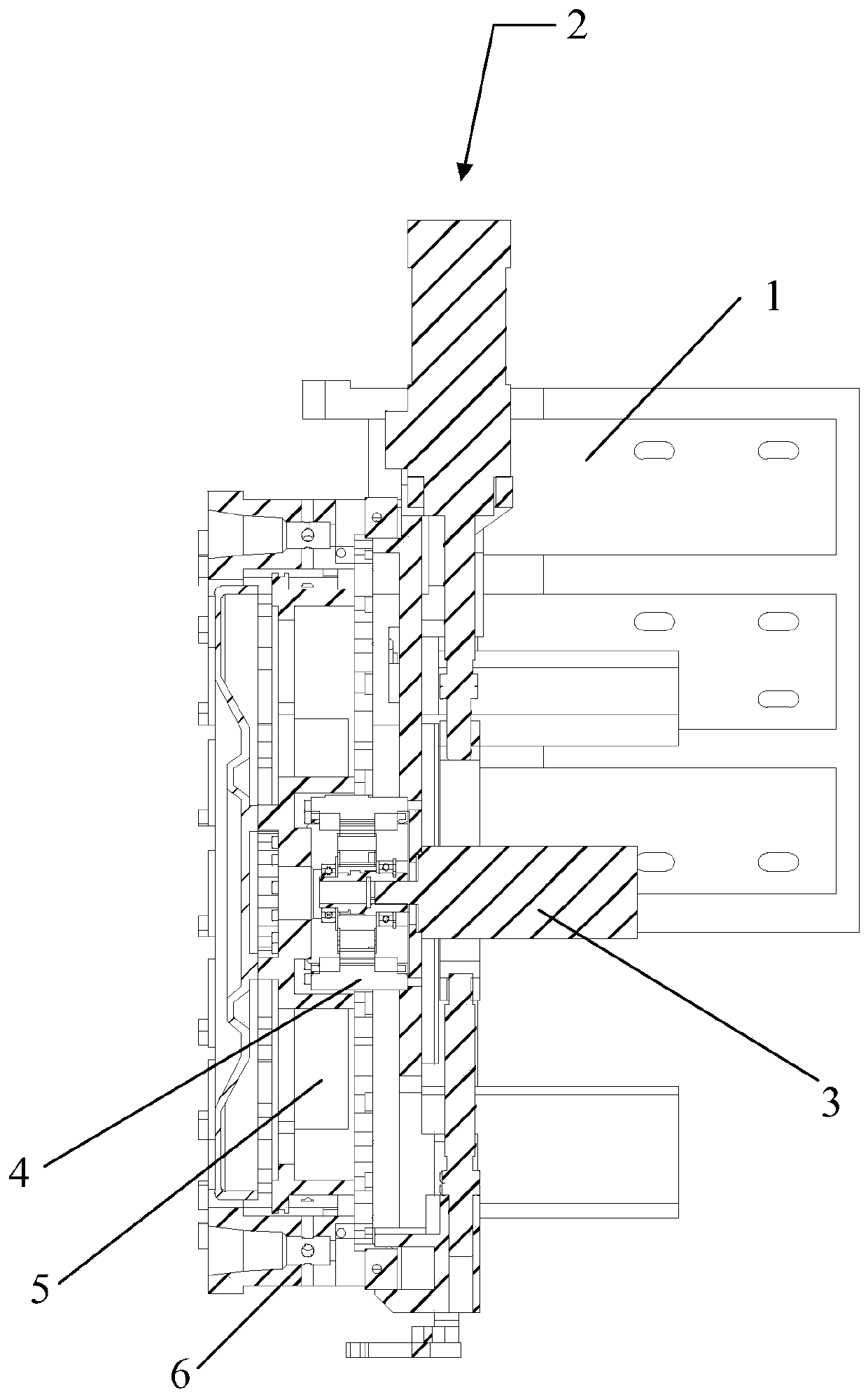

[0030] refer to Figure 1-Figure 4 , figure 1 It is a schematic front view of the CNC machine tool magazine according to the first embodiment of the present invention, figure 2 yes figure 1 The schematic diagram of the back of the CNC machine tool magazine in image 3 yes figure 1 The schematic diagram of the cross-section of the CNC machine tool magazine along A-A, Figure 4 yes figure 1 An exploded schematic diagram of the CNC machine tool magazine in . In this embodiment, the CNC machine tool magazine includes a body support 1 , a knife driving unit 2 , an indexing unit 34 , a cutter head 5 and a tool holder 6 .

[0031] The cutter disc 5 and the cutter cover 6 are located on one side of the body support 1 , and the indexing unit 34 and the knife striking unit 2 are located on the other side of the body support 1 . The cutter cover 6 is located on the circumferenc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap