Motor vehicle rear parcel shelf made of composite material

A technology for composite materials and trunks, which is applied in the field of rear trunk partitions of motor vehicles, and can solve problems such as reducing vehicle quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

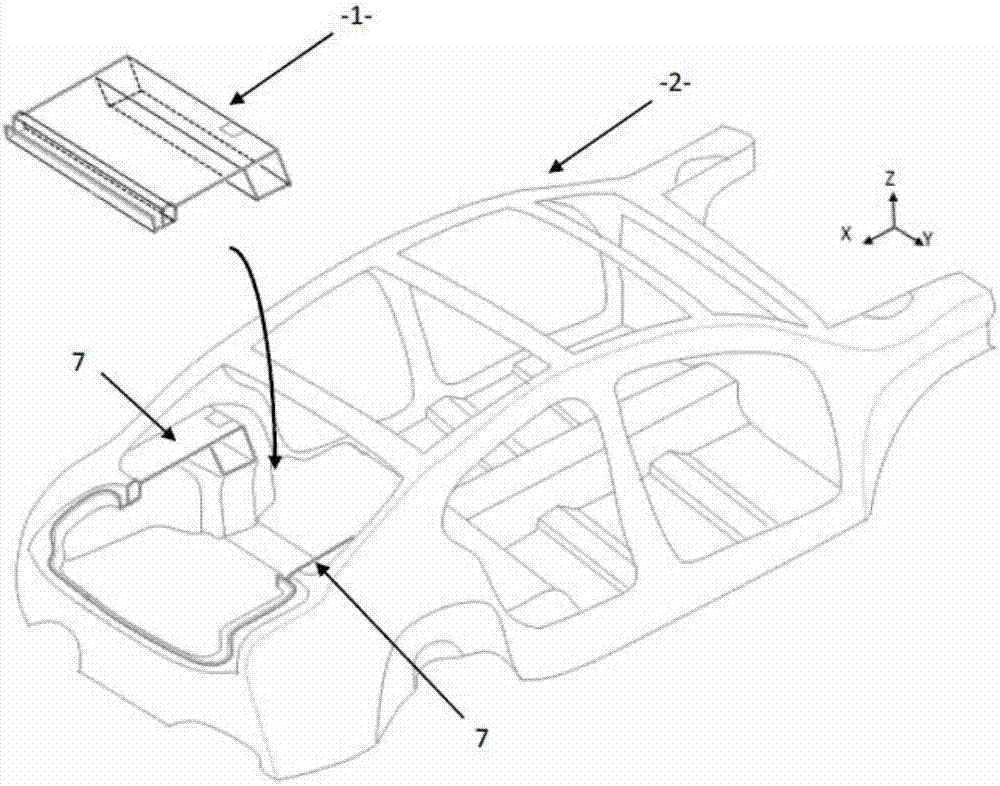

[0037] now refer to figure 1 , which shows a body in white 2 of a motor vehicle and a trunk partition 1 of a motor vehicle according to the invention for separating a passenger compartment of a motor vehicle from a trunk of a motor vehicle.

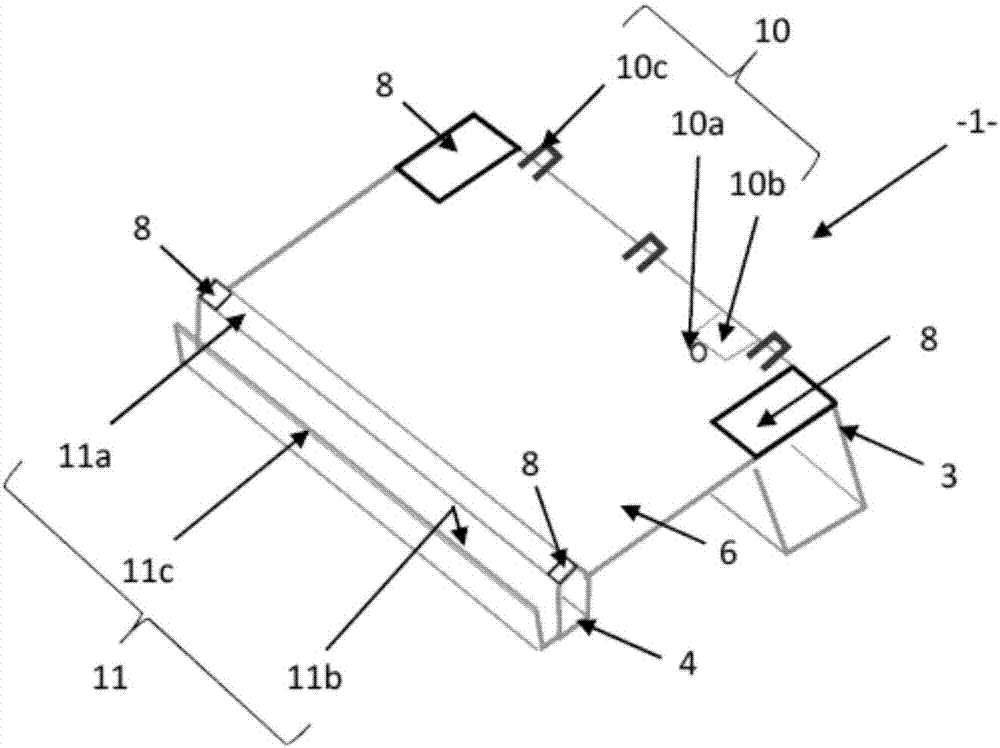

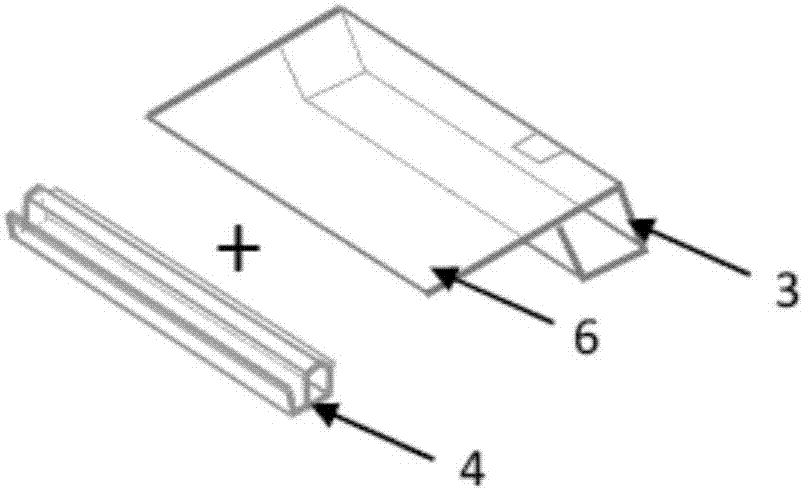

[0038] exist Figure 2A to Figure 2E Among them, more specifically, the rear trunk bulkhead 1 includes the following elements:

[0039] - a first beam 3 consisting of at least one skin made of composite material adapted to be connected in a rigid manner to both body sides 7 (side walls) and which may comprise a connection with the first a first set of functional interfaces 10 molded together by the beams 3;

[0040] - a second beam 4 consisting of at least one skin made of composite material adapted to be connected in a rigid manner with the two body sides 7 and which may comprise molding with the second beam 4 a second functional interface group 11 together, at least one of the beams 3, 4 comprising a set of stiffening ribs 5; and

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com