Novel hydrogen peroxide multistage catalytic decomposition type gas generator

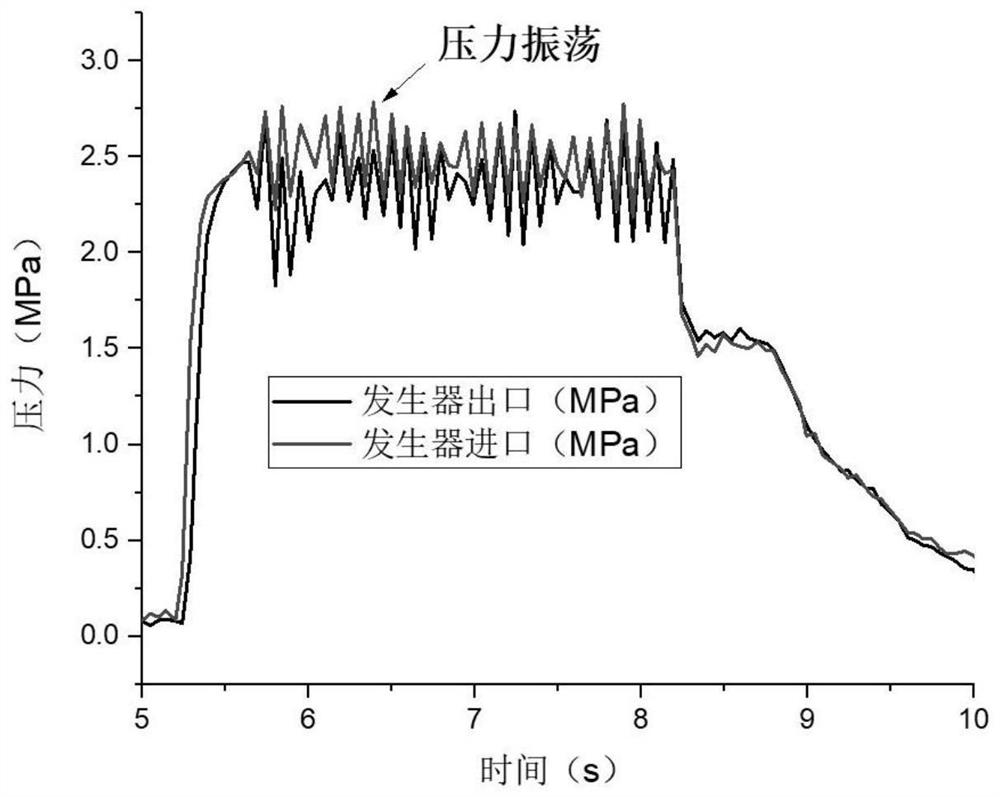

A technology of gas generator and hydrogen peroxide, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of pressure oscillation at the inlet and outlet of the generator, and temperature at the outlet of the generator Problems such as lowering and reducing the working efficiency of the generator, to achieve the effect of matching pressure drop, suppressing pressure oscillation, ensuring structural stability and flow resistance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

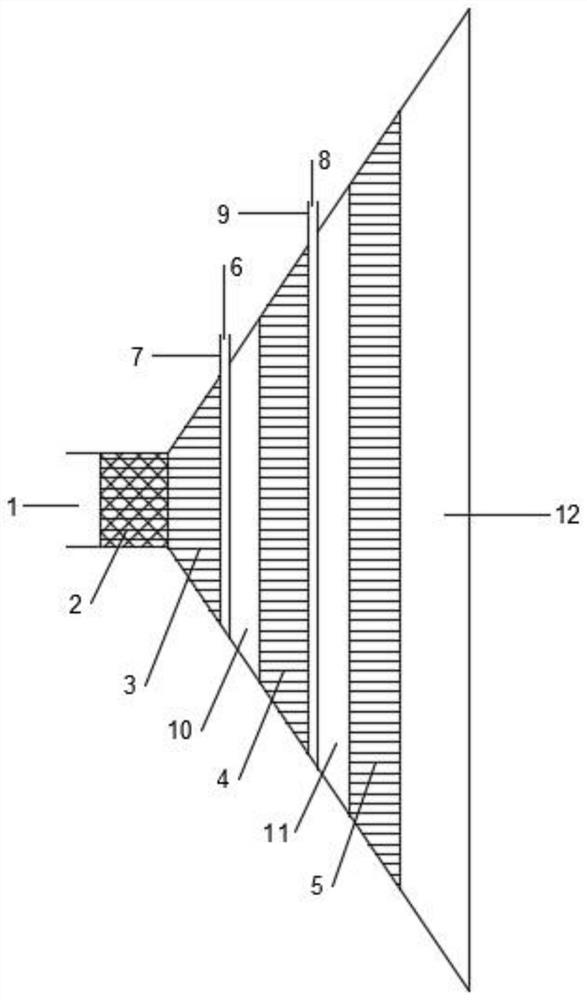

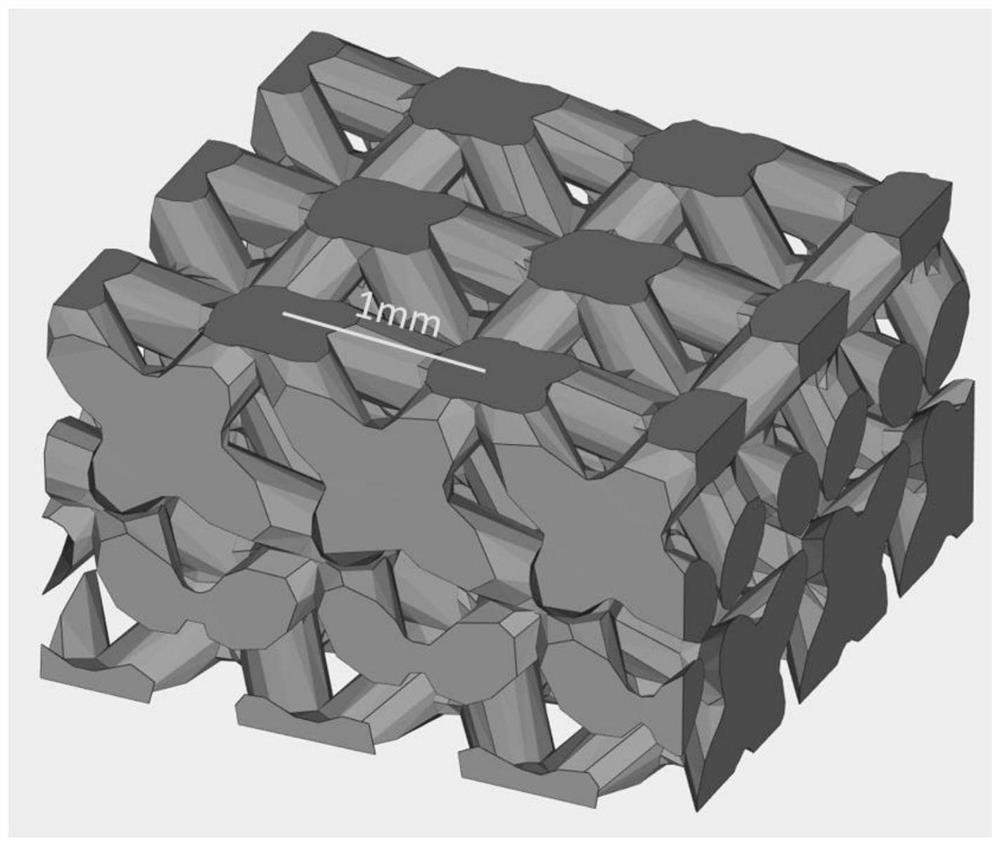

[0032] In this embodiment, as shown in Figure 2-4, a novel hydrogen peroxide multi-stage catalytic decomposition gas generator includes a first-stage hydrogen peroxide inlet 1, and the downstream of the first-stage hydrogen peroxide inlet 1 is sequentially provided with 1 Two-stage hydrogen peroxide silver mesh catalytic bed, one-stage lattice structure 3, two-stage hydrogen peroxide gas-liquid injection plate 7, two-stage downstream mixing chamber 10, two-stage lattice structure 4, three-stage hydrogen peroxide gas-liquid injection Injection disk 9, 3rd stage downstream mixing chamber 11, 3rd stage lattice structure 5 and generator outlet 12, 2nd stage hydrogen peroxide gas-liquid injection disk 7 is provided with 2nd stage hydrogen peroxide inlet 6, 3rd stage hydrogen peroxide gas A three-stage hydrogen peroxide inlet 8 is provided on the liquid injection plate 9 . The casing of the gas generator, the first-level lattice structure 3, the second-level lattice structure 4, the...

Embodiment 2

[0035] On the basis of embodiment 1, the using method of this novel hydrogen peroxide multistage catalytic decomposition type gas generator is as follows:

[0036] S1: Hydrogen peroxide enters the first-level hydrogen peroxide silver mesh catalyst bed 2 through the first-level hydrogen peroxide inlet 1, and after rectification and distribution, it is decomposed into high-temperature oxygen and water vapor and flows into the first-level lattice structure 3; in this step The time of hydrogen peroxide feeding is sufficient to fully activate the silver screen. When the gas at the outlet 12 of the generator is observed to change from white mist to transparent or when the temperature of the decomposed gas reaches the decomposition temperature, the hydrogen peroxide inlet 6 of the second stage can be passed through. into hydrogen peroxide;

[0037] S2: When the temperature of the decomposed gas at the outlet 12 of the monitoring generator reaches the decomposition temperature, hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com