Rolling type end face seal dissepiment

An end-face sealing, rolling technology, applied in the direction of the engine seal, diaphragm, engine components, etc., can solve the problems of not working properly, reducing the technical indicators of equipment design, and the end face diaphragm not considering the influence of axial force, etc., to achieve the scope of application Wide, improve technical indicators and production efficiency, good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

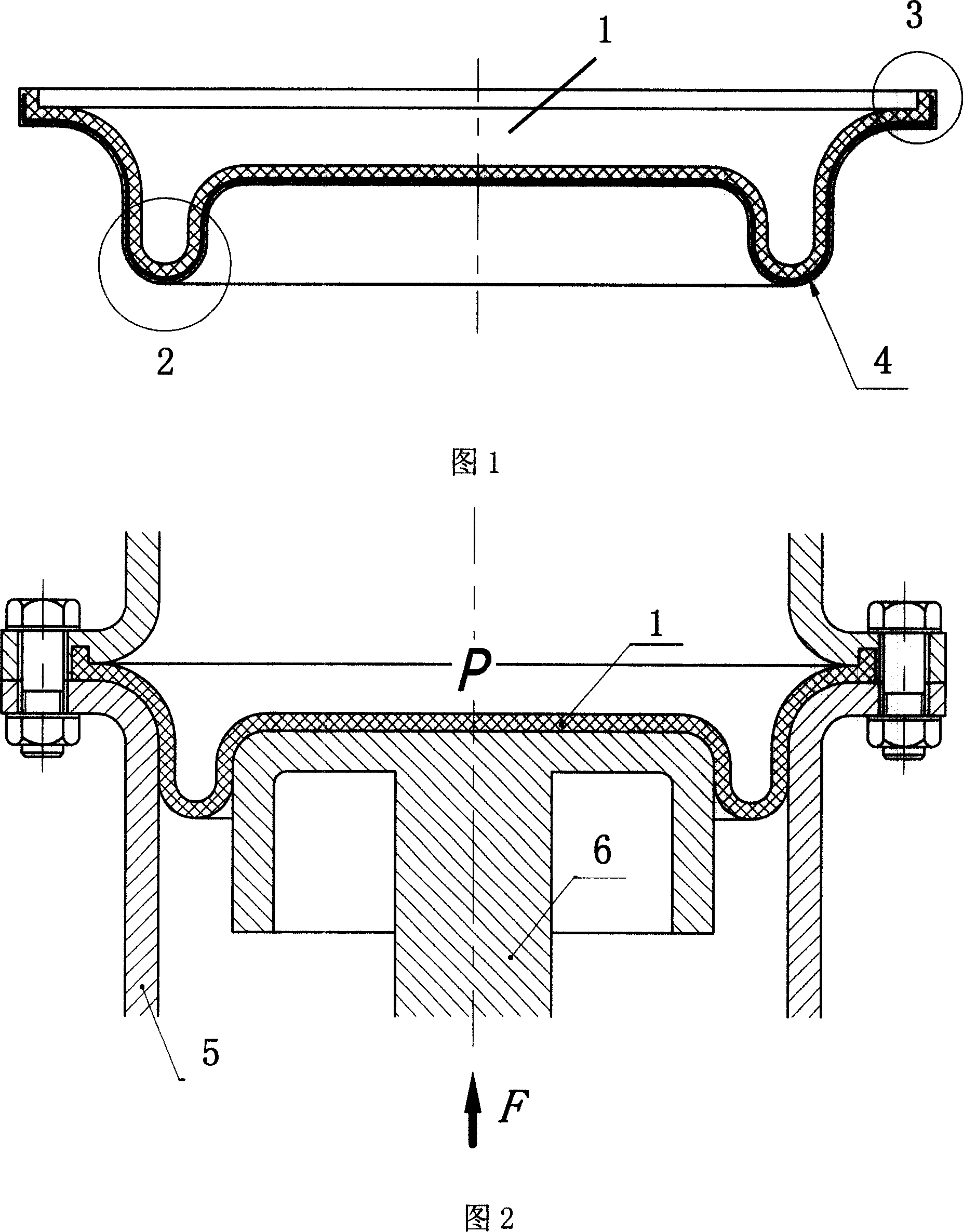

[0014] As shown in FIG. 1 , the rolling type end face sealing diaphragm 1 is in the shape of a disc, with an annular arc boss 2 on the inner surface and a flange 3 on the outer circumference. The rolling end face sealing diaphragm is made of two kinds of materials, the inner and outer layers are sealing diaphragm, and the middle layer is mesh braid 4; the sealing diaphragm is made of rubber and other materials with high elasticity, and the mesh braid is made of high strength Cotton thread, carbon fiber and other materials.

[0015] As shown in Figures 1 and 2, the rolling end face seal diaphragm works like this: the flange 3 on the outer circumference of the rolling end face seal diaphragm is installed on the cylinder body 5, which acts as a seal equivalent to the ○ ring, and the The high-pressure chamber in the cylinder body 5 is isolated from the normal pressure chamber; when the piston 6 in the cylinder body 5 moves axially within a certain range, the diaphragm at the ring-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com