Gilled radiator

A radiator and chip technology, applied in the field of chip radiators, can solve problems such as inability to change, inability to adjust internal excessive pressure, small space, etc., and achieve the effect of improving operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0035] The invention includes cooling fins, air intake pipes, liquid return pipes, gas storage tanks and the like.

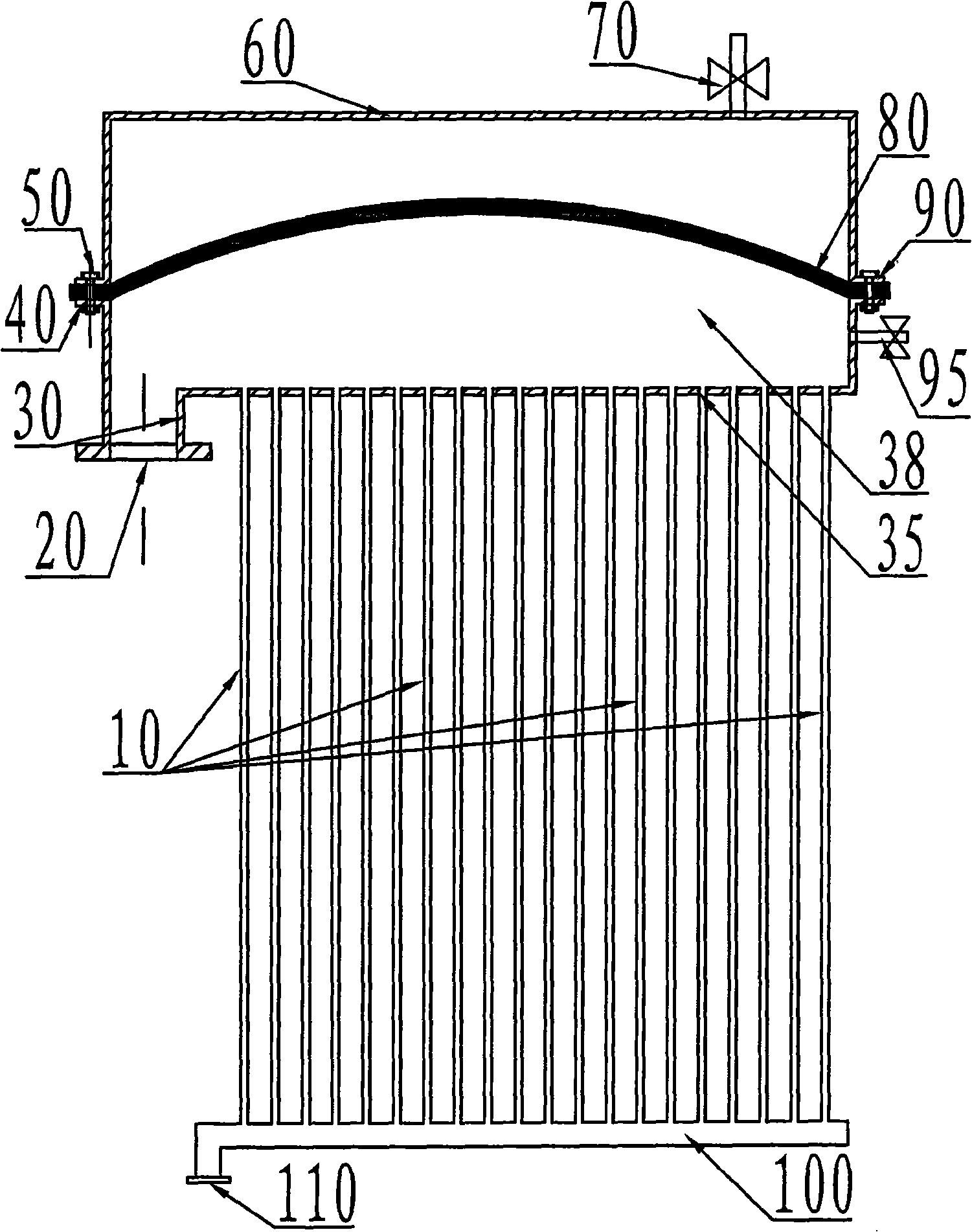

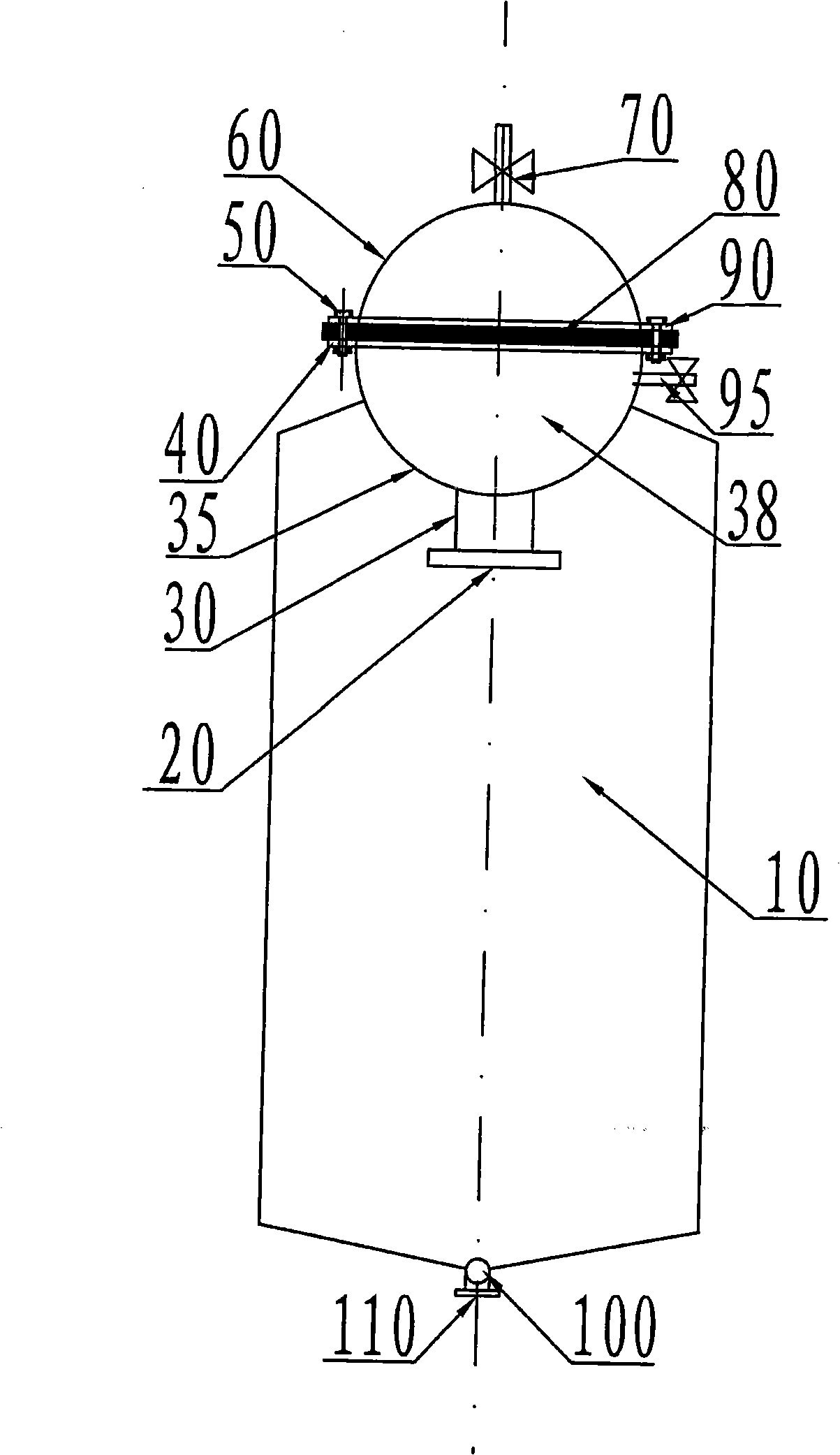

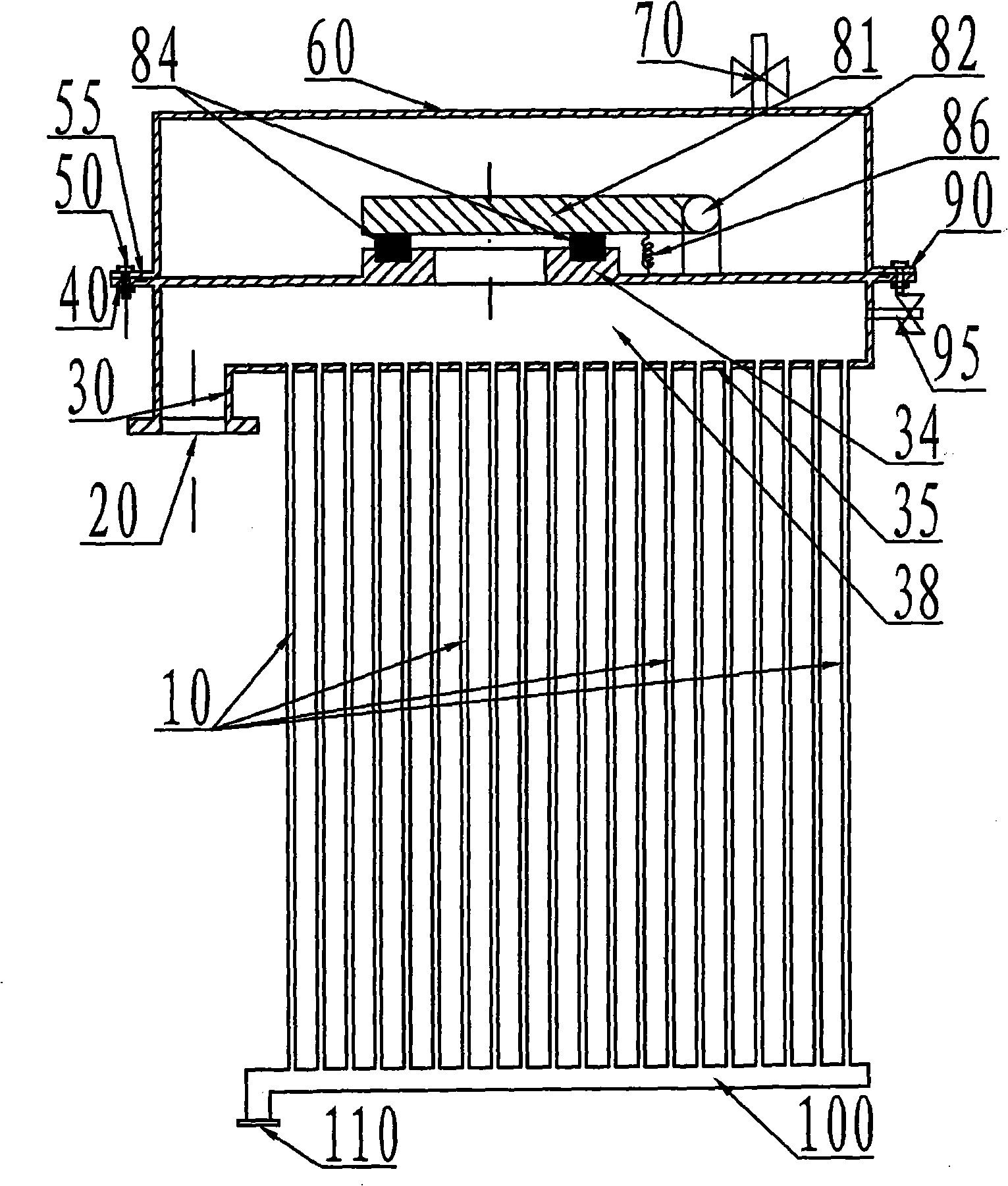

[0036] figure 1 and figure 2 Shown is one of the specific embodiments of the present invention. like figure 1 and figure 2 As shown, the heat sink 10 is a sealed container made of a thin metal plate with a cavity inside through welding and other processes, and can withstand a certain internal pressure. The surface of the sheet metal can have ridges or fins of various shapes. In order to reduce corrosion, the inner wall can also be painted. For a fin radiator, its radiator consists of several groups. The upper end of a group of cooling fins is connected with the gas storage tank through welding, casting and other processes, and the lower end is connected with the liquid return pipe 100 through welding, casting and other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com