Device and method for preparing non-polar indium nitride nanocrystalline thin film

An indium nitride nanometer and a technology for preparing devices, which are applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of unsuitability for commercial development, poor quality of InN films, unfavorable thermal stability, etc. The effect of poor thermal stability, uniform morphology and size, and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

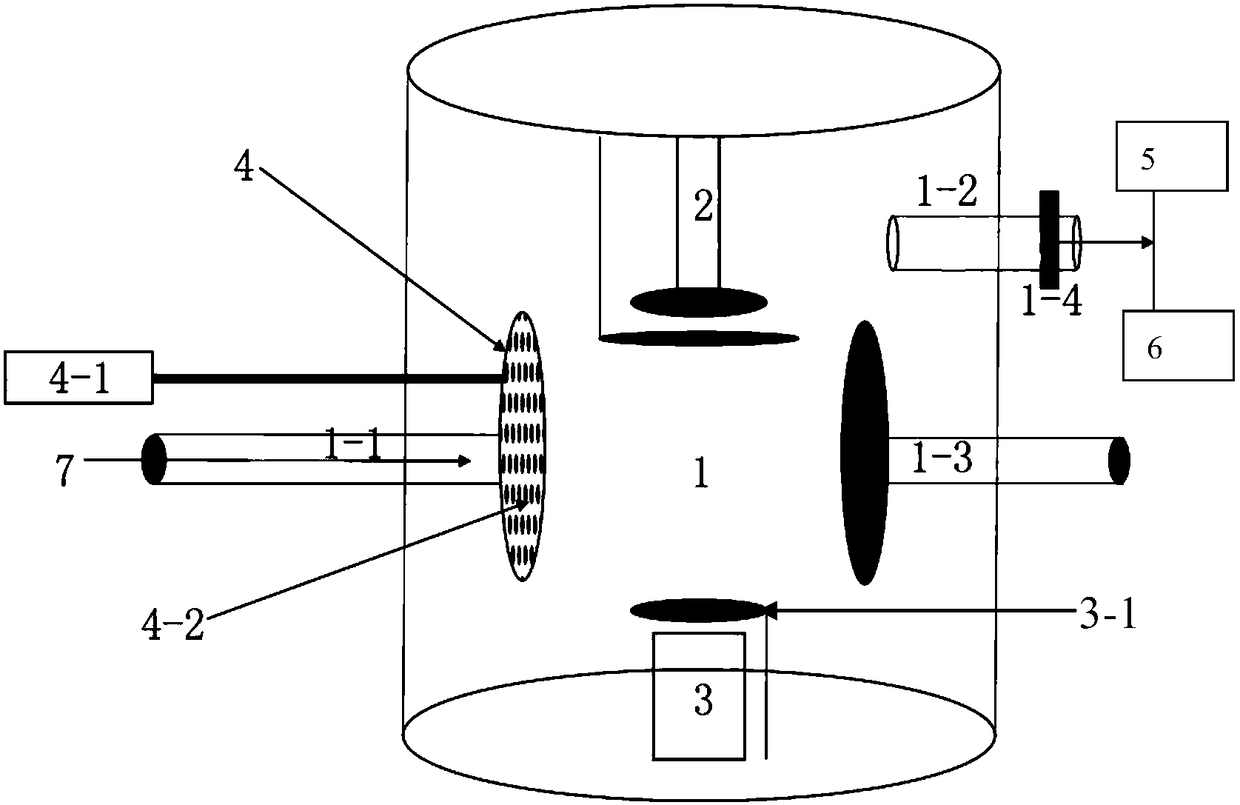

[0055] A device for preparing a non-polar indium nitride nanocrystalline thin film, the schematic diagram of which is shown in figure 1 , specifically including a reaction chamber 1, a substrate substrate sample stage 2, a beam source furnace 3, a radio frequency electrode 4, a vacuum mechanical pump 5, a molecular pump 6 and a nitrogen gas supply system 7;

[0056] The reaction chamber 1 is a closed chamber, wherein the substrate sample stage 2, the beam source furnace 3 and the radio frequency electrode 4 are all arranged in the reaction chamber 1; wherein the substrate sample stage 2 is arranged on Above the reaction chamber 1, the beam source furnace 3 is arranged below the reaction chamber 1;

[0057] The two sides of the reaction chamber 1 are provided with an air inlet 1-1, an air outlet 1-2 and a grounding port 1-3, the air inlet 1-1 is opposite to the grounding port 1-3, and the air outlet 1-2 is set in the reaction chamber Above the opposite side of the body air inl...

Embodiment 2

[0079] A preparation device for non-polar indium nitride nanocrystalline thin film, same as embodiment 1.

[0080] A method for preparing a non-polar indium nitride nanocrystalline thin film, using the above-mentioned device, including the same steps as in Example 1, except that the substrate used is a quartz plate.

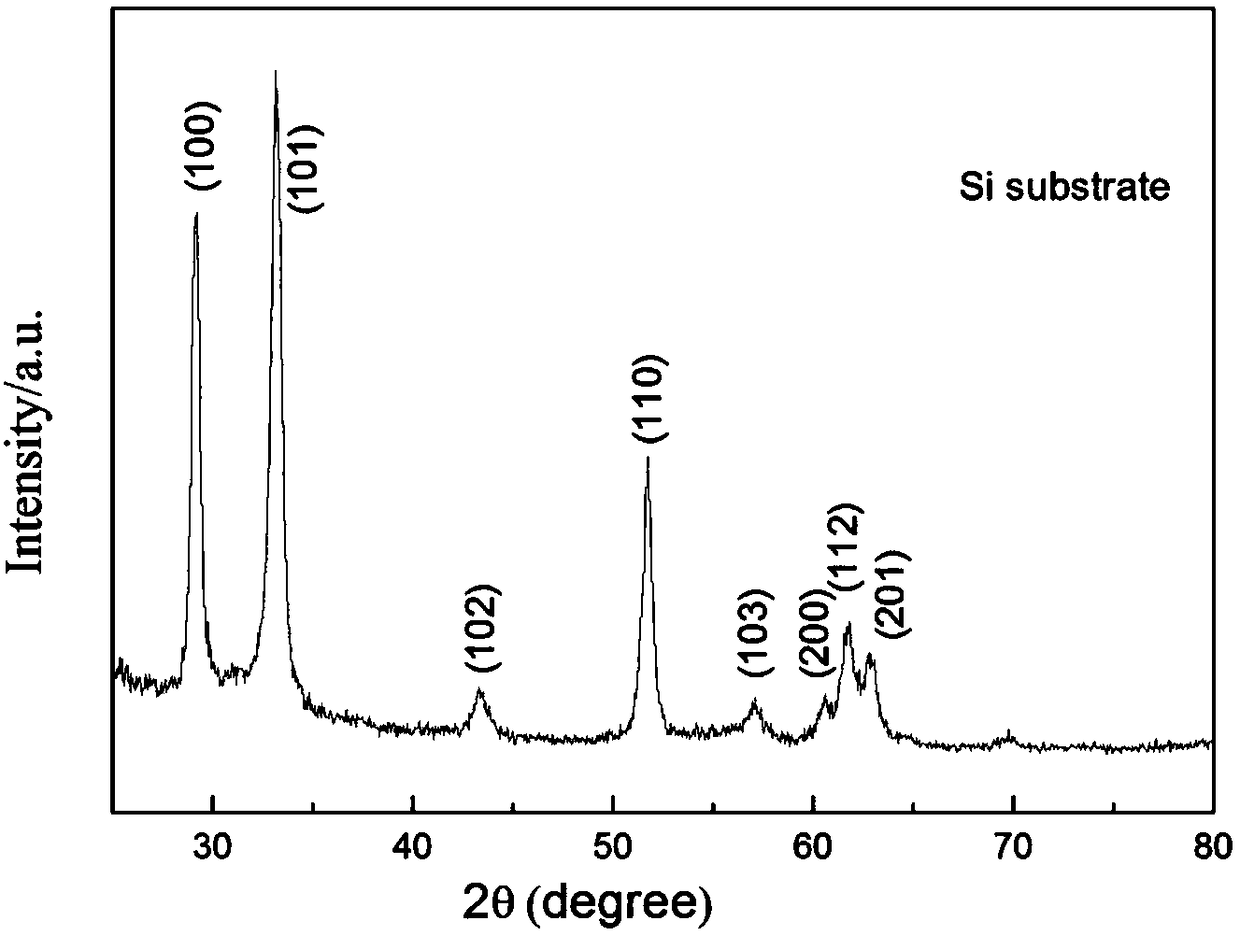

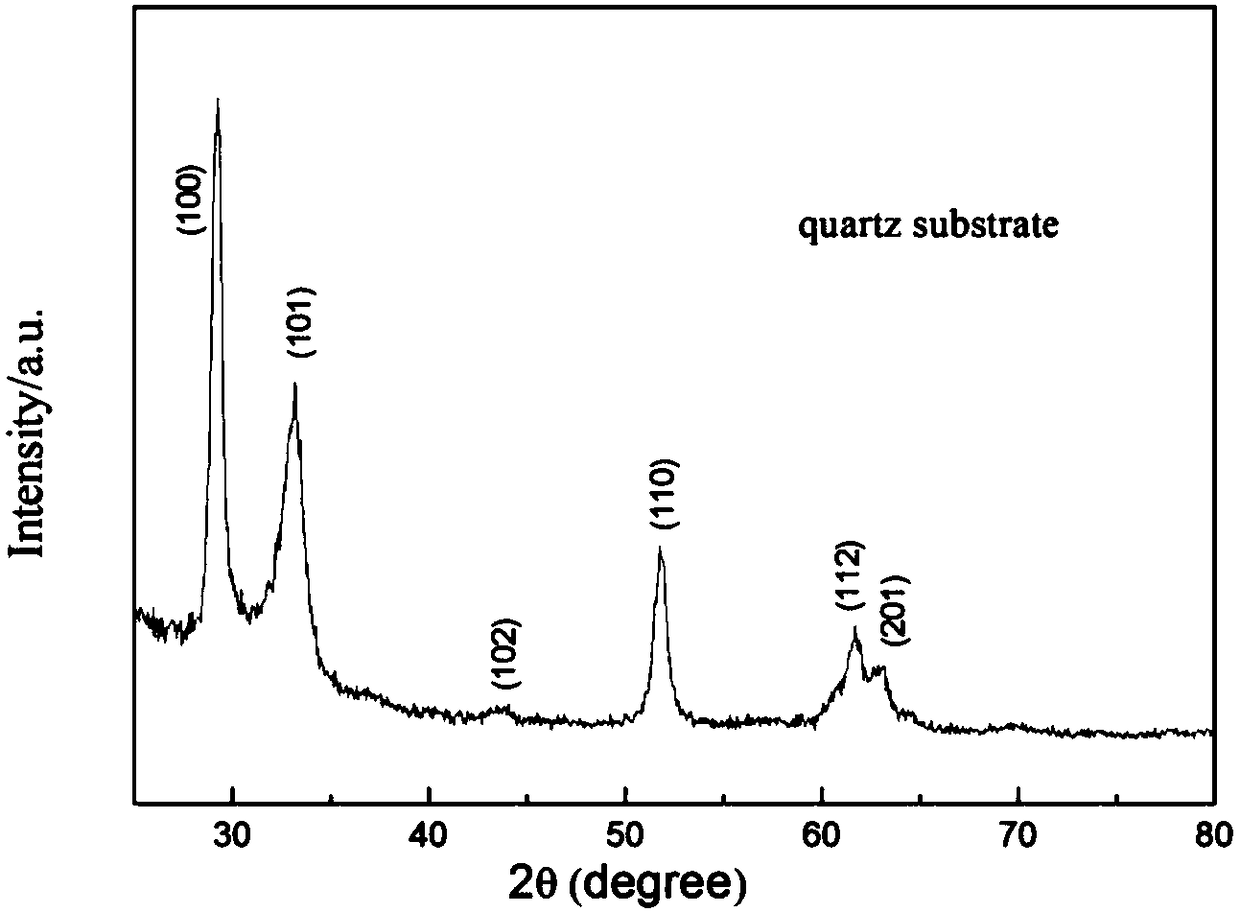

[0081] The XRD spectrum of the InN nanocrystalline film prepared on the quartz substrate in this embodiment is shown in image 3 ,from image 3 In the XRD analysis, it can be seen from the figure that there are obvious characteristic peaks, corresponding to (100), (101), (102), (110), (112) respectively, and the diffraction peaks are obvious, which is wurtzite The structure of the InN crystal, analyzed by Jade software, is consistent with the diffraction peak of the standard InN, indicating that the prepared InN nanocrystalline film has high crystal quality, high purity, and no impurity peaks.

[0082] The SEM image of the InN nanocrystalline film prepared on t...

Embodiment 3

[0084] A preparation device for non-polar indium nitride nanocrystalline thin film, same as embodiment 1.

[0085] A method for preparing a non-polar indium nitride nanocrystalline thin film, using the above-mentioned device, including the same steps as in Example 2, except that the temperature of the substrate sample stage is 450°C.

[0086] The SEM image of the InN nanocrystalline film prepared on the quartz substrate in this embodiment is shown in Figure 7 ,from Figure 7 , it can be seen that the prepared InN nanocrystalline thin film has uniform morphology and size, and is closely arranged on the quartz substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com