Preparation method of hollow or solid spherical metal powder

A metal powder and metal powder technology, applied in the field of materials, can solve the problems of difficult control of powder particle size and shape, unfavorable industrial production, irregular powder shape, etc., and achieve high sphericity, improved powder purity, flow good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

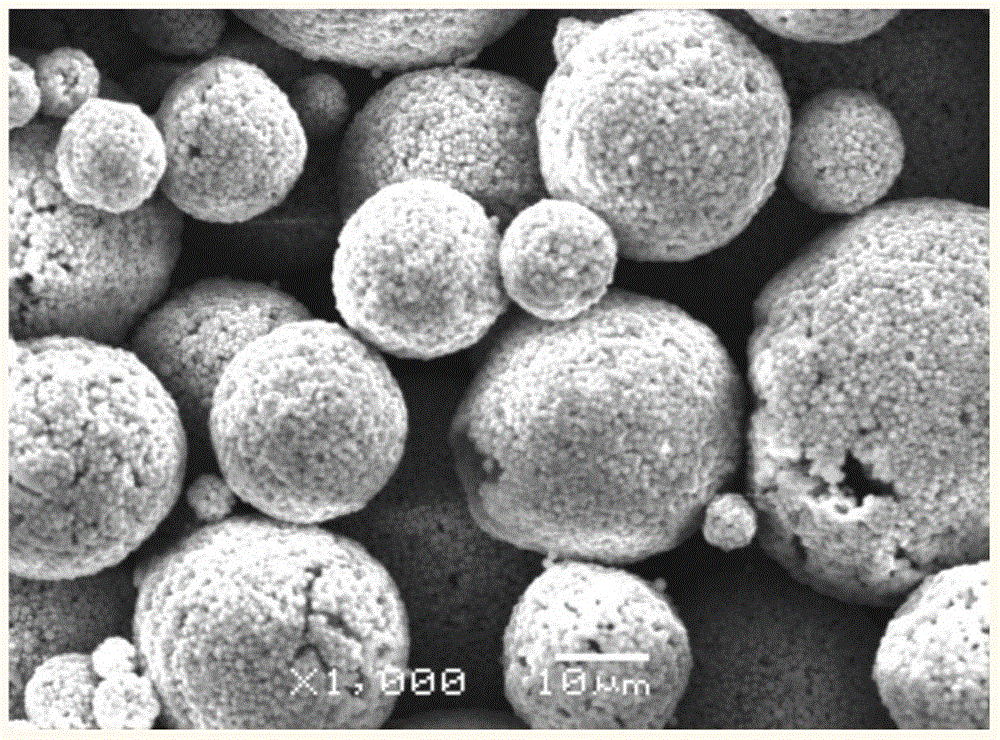

Embodiment 1

[0036] (1) Using Ni powder with an average particle size of 0.6 micron as raw material, mix Ni powder, water-based solvent, mixed binder and dispersant according to the mass ratio of 1:0.43:0.03:0.002, and put it into the basket sand Grind and disperse in a mill for 12 hours, and finally add n-butanol accounting for 0.1‰ of Ni powder as a defoamer, and continue stirring for 1 hour to obtain a slurry. Wherein, the water-based solvent is a mixed solution of deionized water and absolute ethanol with a mass ratio of 1:0.5; the binder is a mixed binder of polyvinyl alcohol and phenolic resin with a mass ratio of 1:1.

[0037](2) Use a centrifugal spray dryer to spray dry the slurry. The feed rate is 15kg / h, the inlet and outlet temperatures are adjusted to 300°C and 129°C respectively, and the rotation speed of the atomizing disc is 14000rpm. The particles are pumped away to obtain hollow spherical Ni powder.

[0038] (3) Put the obtained hollow dry particles into heat treatment e...

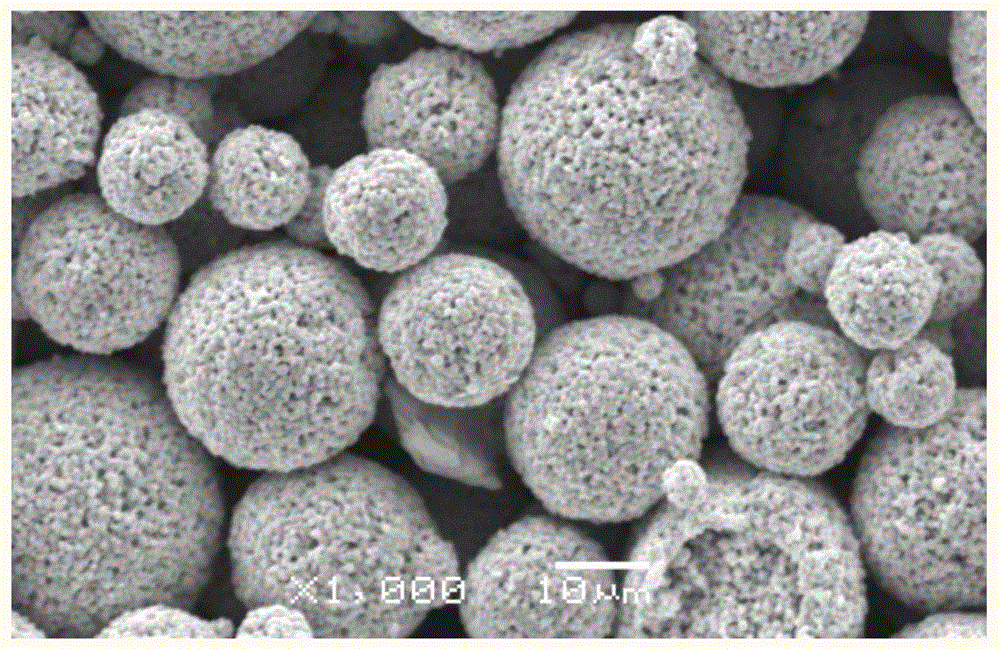

Embodiment 2

[0040] (1) Using Ni powder with an average particle size of 0.6um as raw material, mix Ni powder, water-based solvent, mixed binder and dispersant according to the mass ratio of 1:0.54:0.015:0.002, and put it into the basket sand Grind and disperse in a mill for 12 hours, and finally add n-butanol accounting for 0.1‰ of Ni powder as a defoamer, and continue stirring for 1 hour to obtain a slurry. Wherein, the water-based solvent is a mixed solution of deionized water and absolute ethanol with a mass ratio of 1:1; the binder is a mixed binder of polyvinyl alcohol and phenolic resin with a mass ratio of 1:1.

[0041] (2) Use a centrifugal spray dryer to spray dry the slurry. The feed rate is 18kg / h. The inlet and outlet temperatures are adjusted to 260°C and 103°C respectively. The rotation speed of the atomizing disc is 18500rpm. The particles are pumped away to obtain solid spherical Ni powder.

[0042] (3) Put the obtained solid dry particles into heat treatment equipment, h...

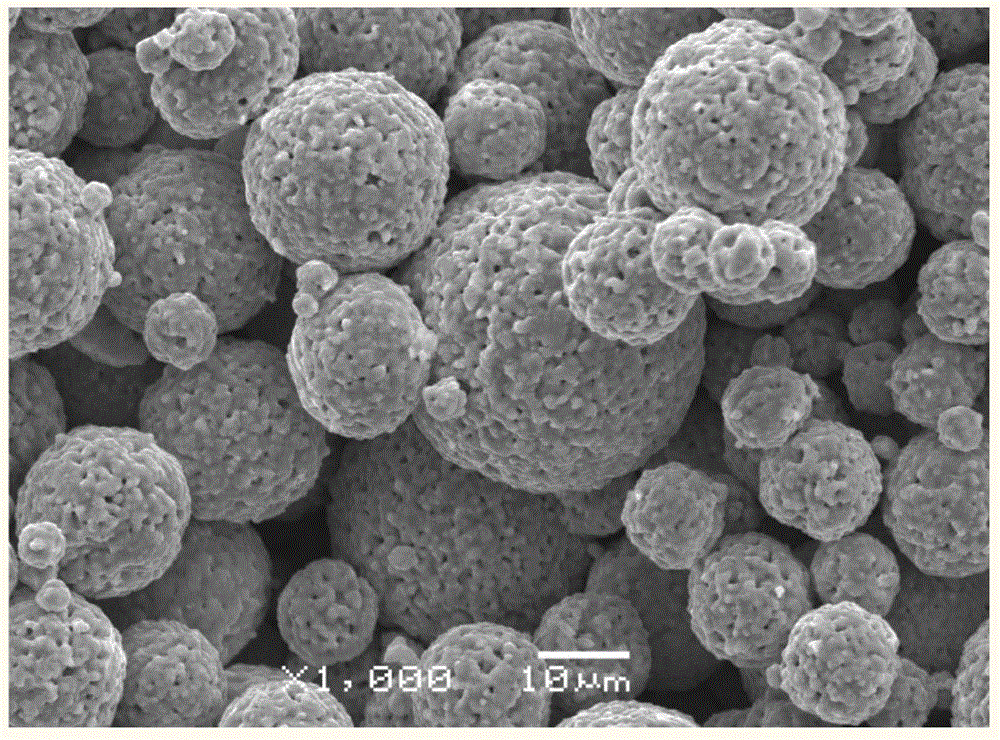

Embodiment 3

[0044] (1) Using CuMn alloy powder (about 25% Mn content) with an average particle size of 1.0um as raw material, mix CuMn alloy powder, water-based solvent, mixed binder and dispersant in a mass of 1:0.82:0.01:0.002 Proportionally mixed, put into a basket sand mill for grinding and dispersing for 12 hours, and finally add n-butanol accounting for 0.1‰ of the mass of Ni powder as a defoamer, and continue stirring for 1 hour to obtain a slurry. Wherein, the water-based solvent is a mixed solution of deionized water and absolute ethanol with a mass ratio of 1:0.67; the binder is a mixed binder of polyvinyl alcohol and phenolic resin with a mass ratio of 1:0.8.

[0045] (2) Use a centrifugal spray dryer to spray dry the slurry. The feed rate is 18kg / h. The inlet and outlet temperatures are adjusted to 300°C and 116°C respectively. The particles are pumped away to obtain solid spherical CuMn alloy powder.

[0046] (3) Put the obtained solid dry particles into heat treatment equip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com