Manufacturing method for upper groove chamber of split vacuum groove chamber of vacuum refining device

A technology of vacuum refining and manufacturing method, applied in the field of vacuum refining devices, can solve the problems of high processing cost and low processing efficiency, and achieve the effects of high processing efficiency, improving processing efficiency and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

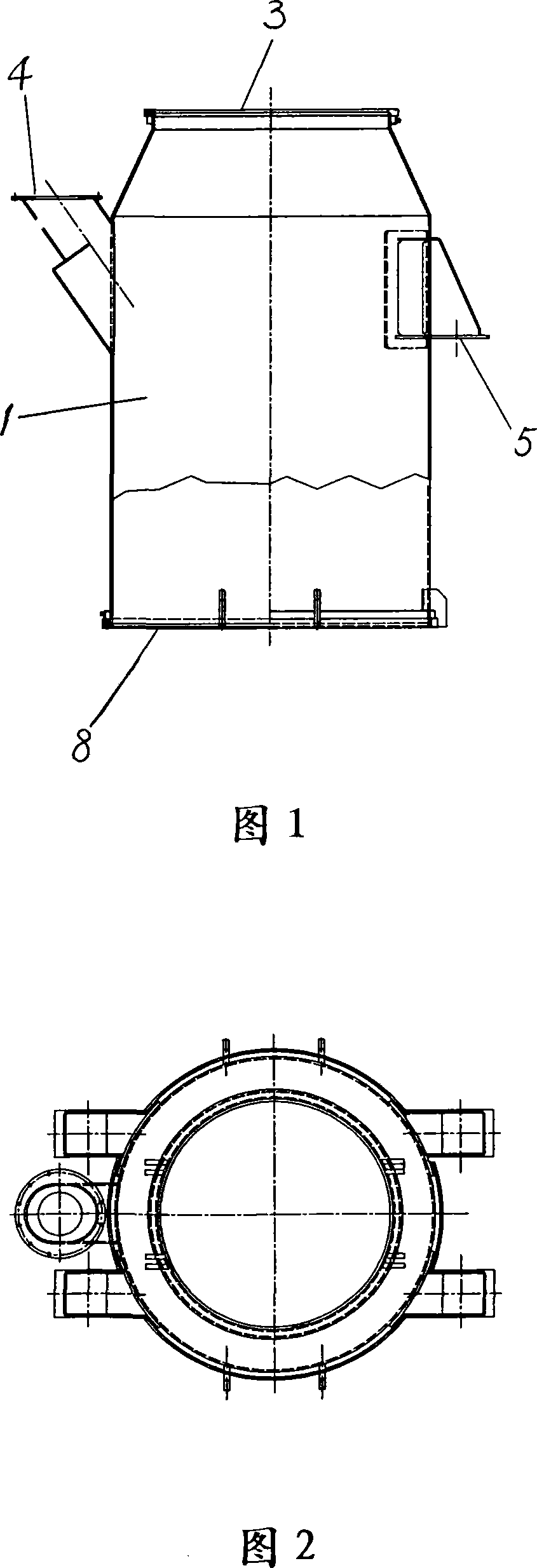

[0020] Referring to the upper tank chamber of the split-type vacuum chamber of the vacuum refining device of Fig. 1 and Fig. 2, the upper tank chamber of the split-type vacuum chamber of the vacuum refining device is manufactured according to the manufacturing method of the present invention, and processed according to the following steps , taking the 300-ton RH vacuum refining unit as an example:

[0021] 1. Divide the upper vacuum chamber 1 of the split type vacuum chamber into upper and lower sections for manufacture, and the joints of the two sections adopt full penetration butt welding joints, and conduct 100% ultrasonic or radiographic testing. The height from the upper flange to the bottom is in the range of 3000-3400mm as the upper section, and the height of the rest is taken as the lower section. The height of the upper section of the split-type vacuum chamber from the top flange 3 to the bottom is in the range of 3000-3400mm, and the upper section includes the top fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com