Method of Machining Impeller by Numerical Control Using Macro Program

A technology of macro program and impeller, which is applied in the field of CNC machining of impeller by using macro program, which can solve the problems of inconvenient program search and modification, difficulty in timely reset, time-consuming transmission, etc., and achieves convenient program search and modification, short debugging preparation time, and improved production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

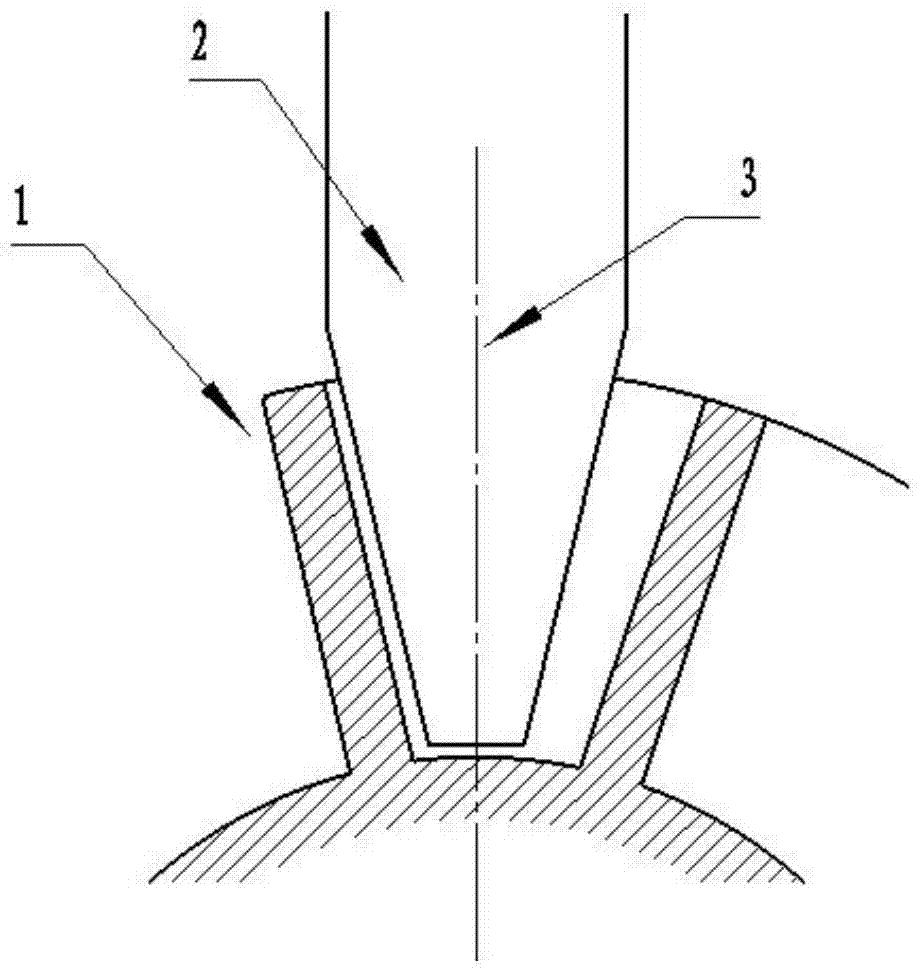

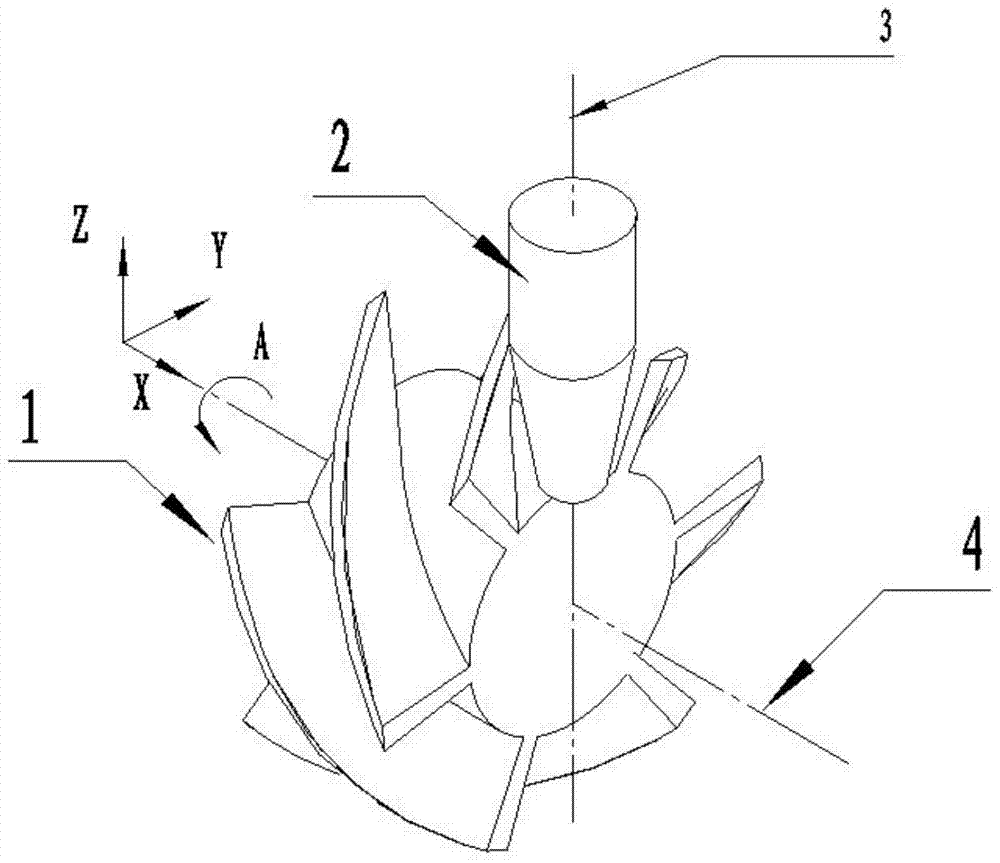

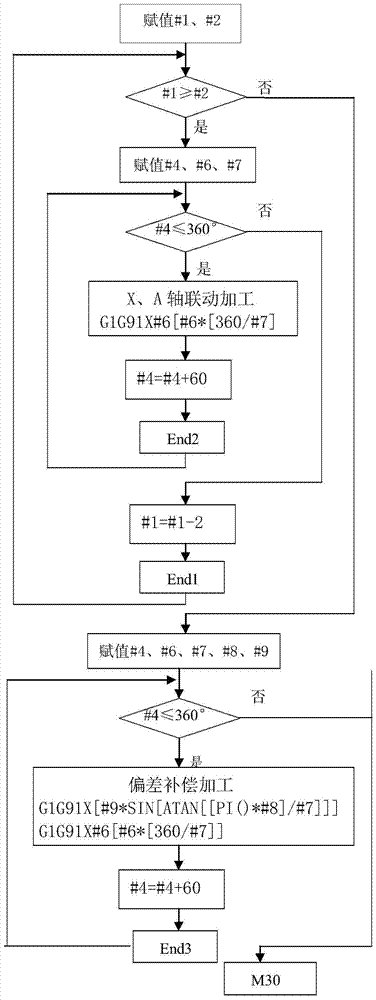

[0019] refer to figure 1 . The impeller part 1 is composed of uniformly distributed blades on the curved surface of the impeller. According to the present invention, the composition characteristics of the blades on the curved surface of the impeller part 1 are analyzed to determine the processing route. In the establishment of the mathematical model and the cycle body, establish the motion trajectory function formula A=[X*[360 / impeller lead]] between the impeller machining rotary axis A and the linear motion axis X; in the macro program compilation, set #1 =18, #1 is the Z-direction assignment of the processing depth; #2=6, #2 is the lowest point of the processing depth; the program nesting between the impeller processing depth and the processing angle is determined by the processing depth condition judgment statement WHILE[#1GE# 2] DO1, and blade processing angle cycle judgment statement WHILE[#4LE360]DO2; use G91 relative value command G1G91X#6A[#6*[360 / #7]]F500 to carry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com