A positioning device and laser processing equipment

A positioning device and positioning arm technology, used in metal processing equipment, laser welding equipment, welding equipment and other directions, can solve the problems of glass edge damage, inability to precisely control the clamping force, slow speed, etc., to achieve short replacement time, clamping Constant force, easy to control, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

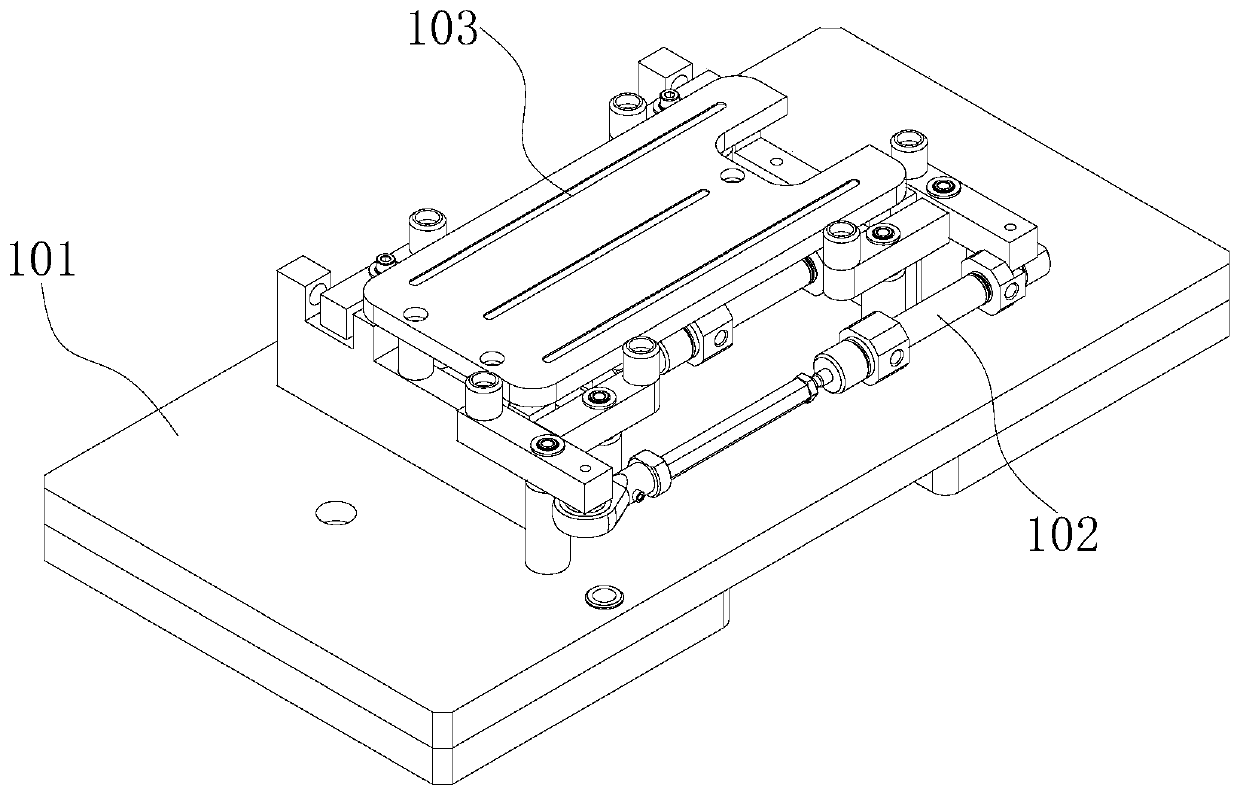

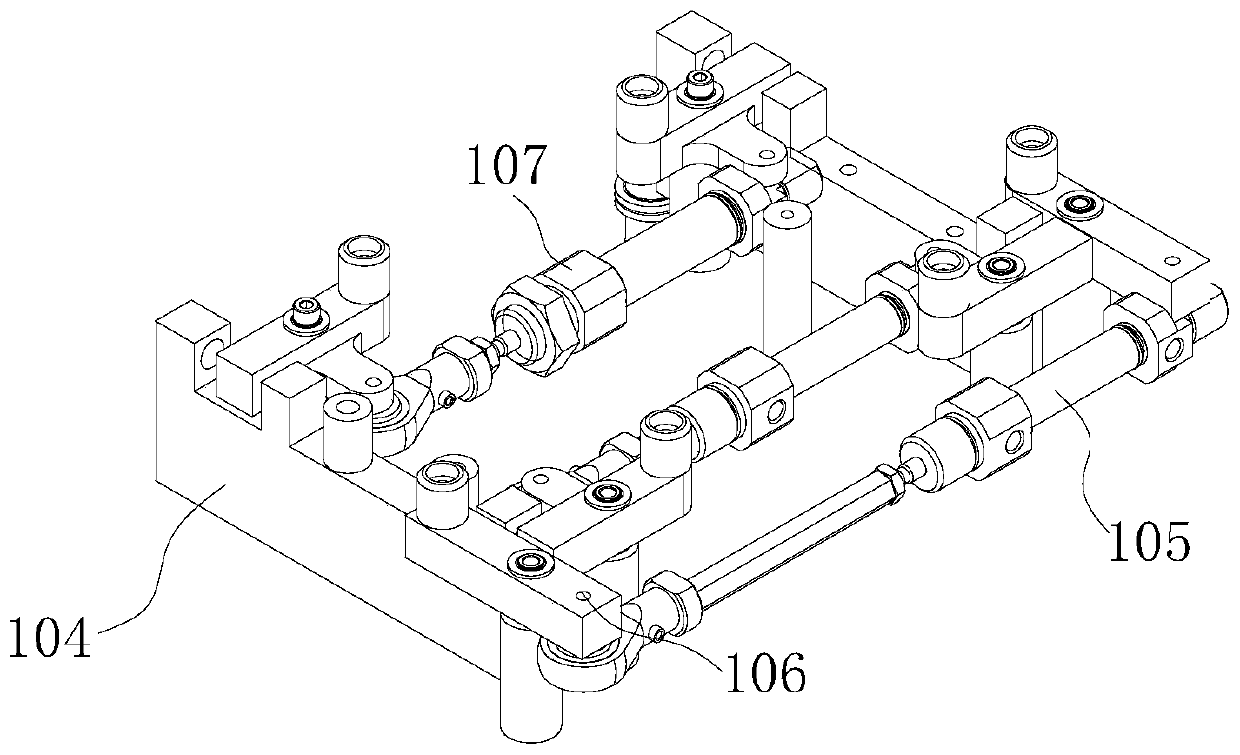

[0043] refer to Figure 1 to Figure 5 , this embodiment provides a positioning device 11, including a support plate 101, a clamping positioning system 102 and a fixing system 103;

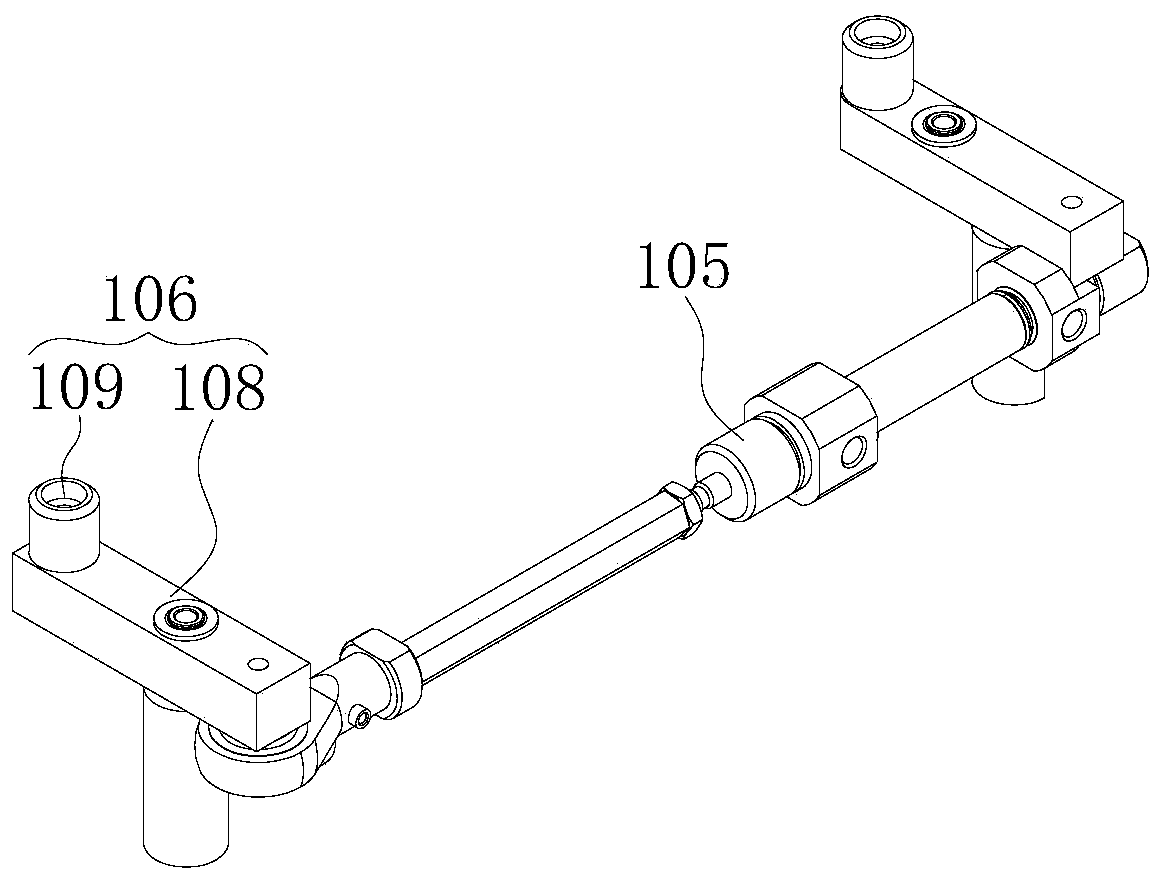

[0044] The clamping positioning system 102 includes a limiting part 104, a first telescopic structure 105, two first clamping parts 106 and two second clamping parts 107, the limiting part 104 is installed on the support plate 101, and the two first clamping parts The tightening part 106 is arranged oppositely, and the two second clamping parts 107 are arranged oppositely, and the connecting line of the two first clamping parts 106 and the connecting line of the two second clamping parts 107 are perpendicular to each other; The two ends are respectively connected with two first clamping parts 106, the second clamping part 107 includes a second telescopic structure 110 and a clamping mechanism, the clamping mechanism is installed on the position limiting part 104, and the second telescopic structure...

Embodiment 2

[0064] refer to Figure 6 , this embodiment also provides a positioning device 11, this embodiment is a further improvement on the basis of the technical solution of embodiment 1, the technical solution described in embodiment 1 is also applicable to this embodiment, embodiment 1 has been disclosed The technical solution is no longer described repeatedly.

[0065] Specifically, the difference between this embodiment and Embodiment 1 is that the positioning device 11 of the positioning device 11 provided by this embodiment includes two clamping positioning systems 102 and two fixing systems 103, two clamping positioning systems 102 and two The two fixing systems 103 are installed on the support plate 101 respectively, the two fixing systems 103 are arranged at intervals, and the two clamping and positioning systems 102 cooperate with the two fixing systems 103 respectively.

[0066] The positioning device 11 provided in this embodiment is provided with two identical devices, w...

Embodiment 3

[0068] This embodiment provides a laser processing device, including a processing device and the above positioning device 11, and the positioning device 11 is located at the output end of the processing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com