Flexible containers with easily variable sizing

A flexible container, container technology, applied in the direction of flexible container, rigid container, soft tubular container, etc., can solve the problems of unsightly, limit the size and shape of decoration, increase the cost of the container, etc. the effect of making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

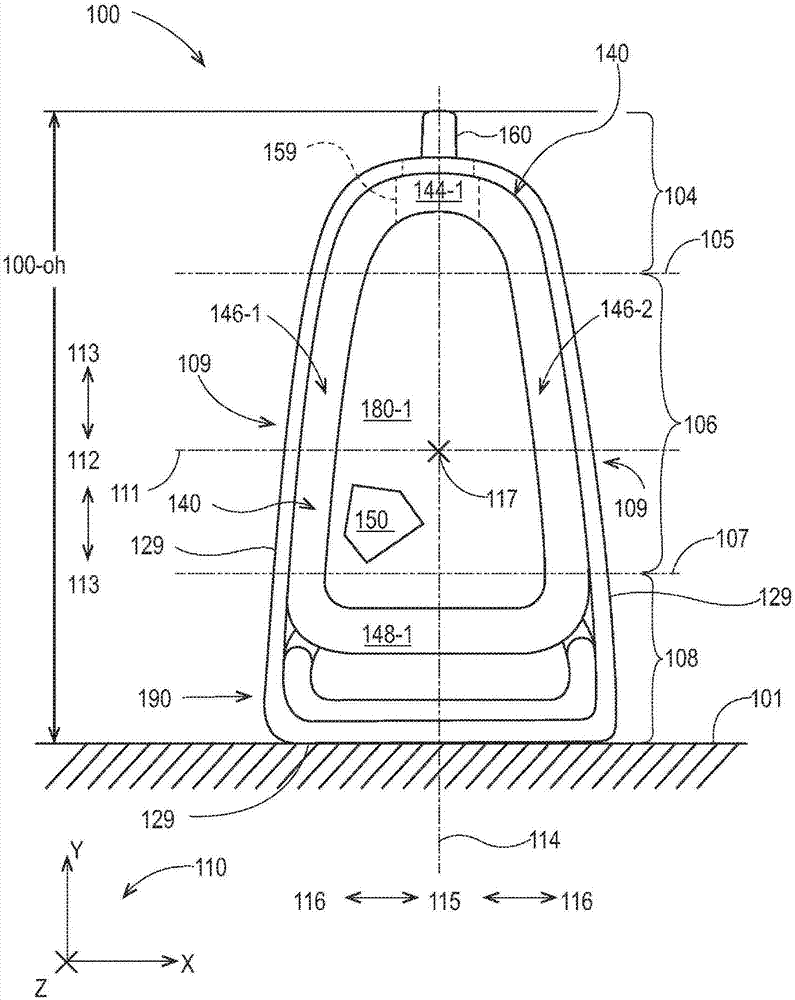

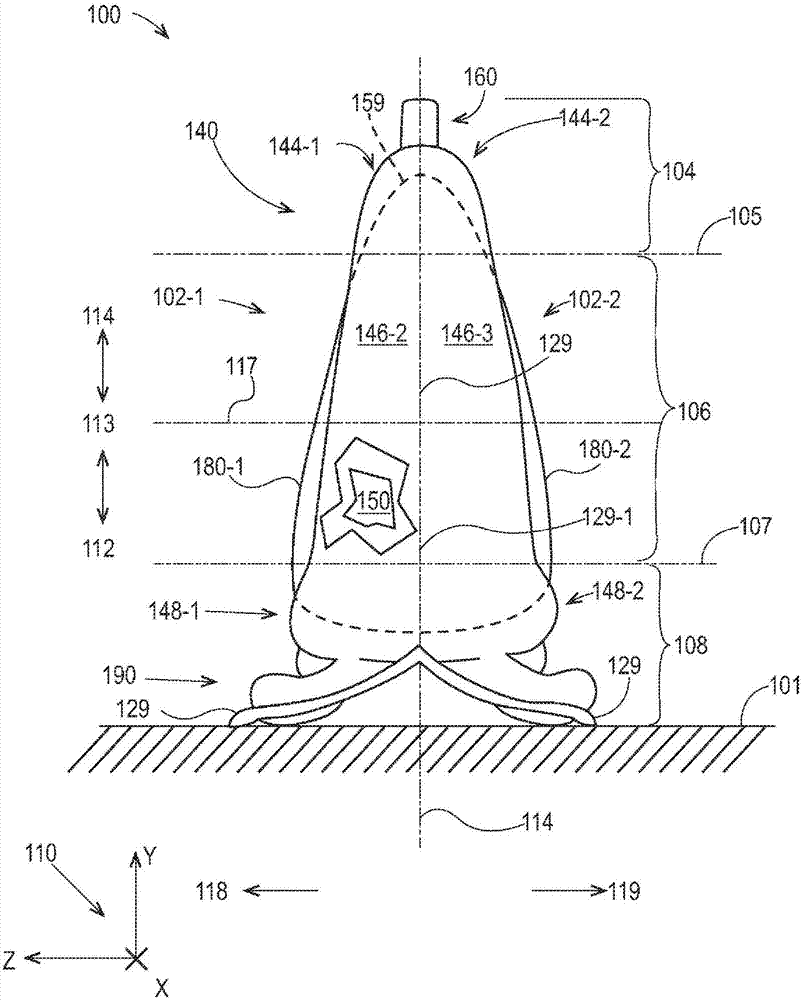

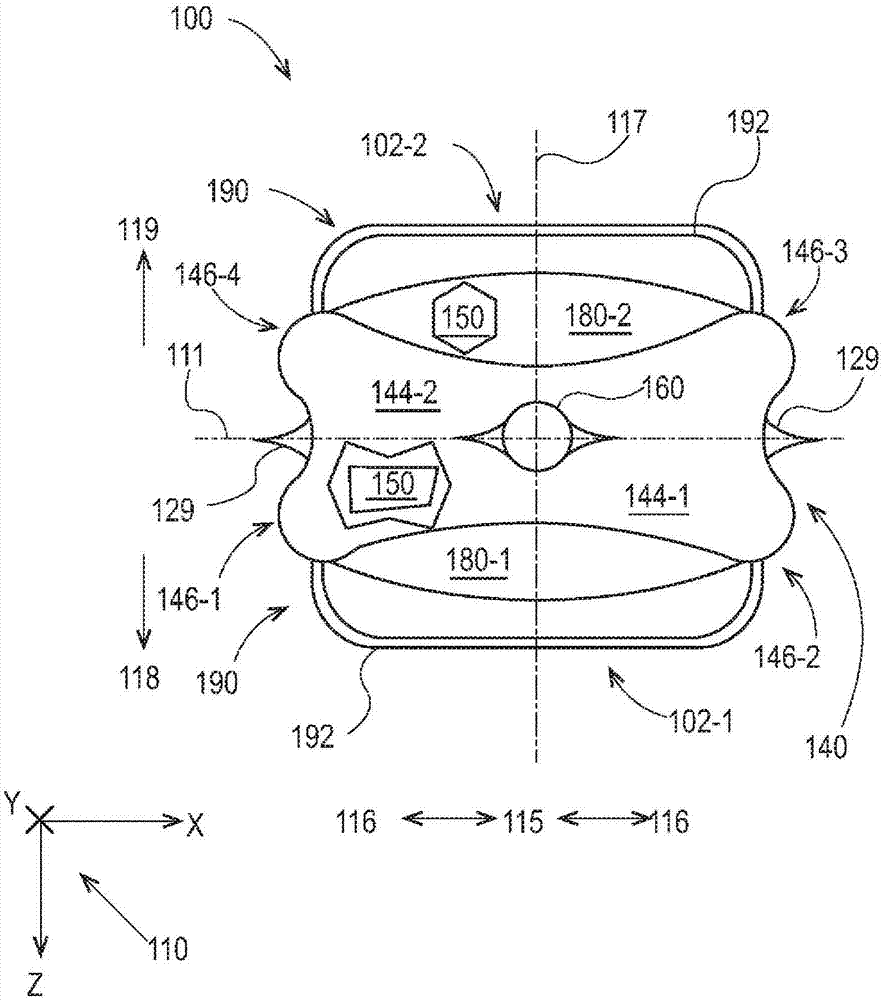

[0175]The present disclosure describes various embodiments of containers made from flexible materials. Because these containers are made of flexible materials, these containers offer several advantages when compared to conventional rigid containers. Specifically, these flexible containers can be configured to be easily resized, thereby allowing product manufacturers to resize products with less expense, less time, and with less fitting when compared to conventional rigid containers. The product size can be changed at low cost because the flexible container processing equipment can be designed to change from one size to another without the need to purchase new equipment. Product dimensions can be changed in less time because flexible container processing equipment can be changed in hours or minutes (or even on the fly) rather than waiting for new equipment. Product dimensions can be changed with less adaptation because flexible containers can be designed with different interna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com